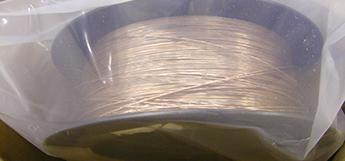

VCI stands for Volatile or Vapor Corrosion Inhibitors. ZERUST® applies VCI technology to inhibit corrosion on metal surfaces. VCI film is packaging that generally consists of polyethylene film that has been impregnated with chemical formulations that are unique to each manufacturer. While the underlying formulations can vary significantly, the finished products function similarly in that they release very low concentrations (typically in parts per ten-thousandth) of invisible corrosion inhibiting vapors into the surrounding air. The vapor molecules subsequently condense onto exposed metal surfaces and form a molecular corrosion shield that can protect against rust and other forms of corrosion for many years. Typical service life is up to three (3) years and even longer in some cases. When the VCI packaging is later removed, all vapor corrosion inhibiting molecules rapidly evaporate. This leaves the metal parts clean and ready for immediate use.

ZERUST® Natur-VCI® Film

The ZERUST®/EXCOR® Natur-VCI® series is a patented (No.11,939,423), internationally certified, fully biodegradable VCI, and compostable packaging material designed to protect against corrosion damage for metals in shipping, storage, and work-in-progress. Natur-VCI® products, with a thickness of 60 microns (2.3 mil) or less, pass the NACE Standard TM0208 VCI corrosion protection test, meet the international standards for compostable plastics, including ASTM D6400, EN 13432, and are certified 100% compostable by TUV Austria.

Features

- Certified Compostable

- Powerful and safe corrosion protection and packaging combined in one step

- Provides enhanced mechanical performance properties in terms of tensile strength, resistance to tearing, elongation at tear, and puncture resistance in conformity with DIN EN ISO 527-3/2/200 and ASTM D1709/A. In many cases, these properties allow the implementation of thinner films (i.e. 2.3 mil rather than 4 mil), allowing customers to reduce the environmental impact

- Metals components are ready for use and assembly directly after being taken out of the packaging

Product Description

End-of-Life Disposal

Natur-VCI®, a fully biodegradable and compostable VCI film, is designed for safe disposal in professional composting facilities. Micro-organisms use the film’s carbon as food, breaking it down completely into humus, water, and CO2. This humus serves as a natural fertilizer or soil amendment in agriculture. Furthermore, Natur-VCI® adheres to the ASTM D6400 standard for aerobically compostable plastics in municipal or industrial facilities. TUV Austria also certifies it (Cert # TA8012004702) under the European EN 13432 standard for compostable and biodegradable packaging.

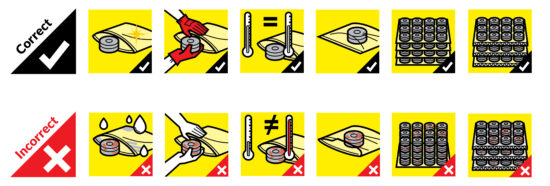

Natur-VCI® fully biodegradable and compostable VCI film diffuses invisible, odorless, and non-toxic ZERUST® Vapor Corrosion Inhibitors (VCI). As a result, these VCI molecules settle onto exposed metal surfaces inside the packaging or enclosure. Once removed from the biodegradable and compostable packaging, the VCI will dissipate from the metal surface. This allows immediate painting, welding, or further processing. Use Natur-VCI® to protect metal components, machined and cast parts, engines, molds, and more from rust and corrosion. Engineered for a broad range of applications, Natur-VCI® is available in a multimetal protection formulation and various packaging types, including rolls, sheets, tubing, and bags, ensuring an ideal packaging solution. Whether in storage or transit, ZERUST® Natur-VCI® Film delivers unparalleled performance.

Biodegradable and Compostable VCI Film Provides Carbon Savings

Replacing 100 metric tons (100,000 kg) of conventional polyethylene plastic VCI packaging with Natur-VCI® achieves the following equivalent environmental benefits.**

|

|

|

|

| 118-ton reduction in CO2 emissions for every 100 metric tons. | CO2 emissions reduction is equivalent to 25 cars driven annually for every 100 metric tons. | Reduction in CO2 emissions equivalent to the consumption of 50,262 Liters of gasoline for every 100 metric tons. | Reduction in CO2 emissions equivalent to the carbon sequestered by 1,951 tree seedlings grown for 10 years for every 100 tons. |

**WARN MODEL. Source: US EPA Greenhouse Gas Equivalencies Calculator (as of September 2019).

Biodegradable and Compostable VCI Film Provides Zero-Waste

End-users can reuse the shipped Natur-VCI® bags to collect food scraps at their facility and send them to their local compost site*. Natur-VCI® meets ASTM D6400 and is certified by TUV Austria (Cert # TA8012004702).

*You can only coat parts with rust preventative oils if the oil is certified compostable.

Why Choose ZERUST®?

For over 50 years, beginning with the invention of Vapor Corrosion Inhibiting (VCI) film, ZERUST® has led the market in quality corrosion solution products. Furthermore, we dedicate ourselves to providing expert corrosion management services and further adding solutions for our customers. In addition, ZERUST® users have access to on-site support from ZERUST®/EXCOR® representatives in more than 70 countries. As a result, our customers have peace of mind when they choose ZERUST® for corrosion control management.

Resources

Availability

ZERUST®/EXCOR® Fully Biodegradable and Compostable Natur-VCI® Film is a made-to-order product with a wide range of custom options, subject to minimum order quantities. For further ordering information, contact your ZERUST®/EXCOR® representative.

| Part Number | |

|---|---|

| Custom Order |