VCI Corrosion Protection: Metal Stamping and Forming Industry

Metal stamping and forming companies commonly have corrosion issues with finished precision metal parts due to high humidity at the manufacturing facilities and improper handling/packaging. Corrosion is an issue not only with the finished goods but also with tooling and dies left in storage when not in use.

Every metal responds differently to metal stamping processes, with most finished metal parts requiring some form of a corrosion inhibitor to protect against atmospheric oxidation, the presence of water, or chemical reactions while the parts are in storage and shipping.

ZERUST® VCI Corrosion Solutions for Metal Stamping

ZERUST® has assisted many stamping and forming companies in protecting their parts and tooling against corrosion using VCI packaging products and corrosion-inhibiting coatings.

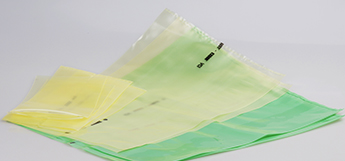

ZERUST® offers a wide array of VCI and corrosion-inhibiting products for the metal stamping and forming industry, ranging from VCI Packaging Films & Paper, VCI Emitters & Diffusers, Rust Removers, Industrial Cleaners & Degreasers, and Rust Inhibitors, Preventatives & Coatings. ZERUST® provides cost-effective and versatile protection against corrosion damage for metals in work-in-progress, shipping, and storage.

- VCI Packaging Film & Paper provides effective corrosion protection and packaging combined in one step

- Metals are ready for use and assembly directly out of VCI Packaging Film & Paper

- ZERUST® offers a wide range of rust inhibitor coatings ranging from oil-based, wax-based, water-based, and grease-based to oil additives

- ZERUST® VCI Products provide safe and effective corrosion protection