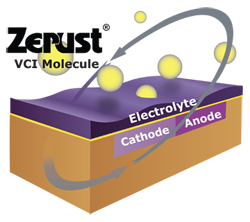

The short answer is “yes if used correctly.” VCI and desiccants function in different ways in reducing the risk of corrosion. VCI emits a corrosion inhibiting chemistry designed to protect the surface of the metal. Desiccant is designed to absorb atmospheric moisture, reducing the electrolyte that accelerates corrosion. VCI and desiccant do not interfere with each respective function, meaning VCI will not stop a desiccant from absorbing moisture, and desiccant will not stop VCI chemistry from emitting.

|

|

The long answer lies in relation to using the desiccants correctly. How can something so simple as absorbing moisture be misused? If not used properly, desiccants can accelerate corrosion on parts inside the package.

|

Many human factors come into play that can affect the efficacy of the desiccant. The two most prevalent are; the storage and handling of desiccant and the placement of the desiccant inside the package.

We have all been in facilities and seen boxes, pails, and drums of desiccant sitting at the packaging workstation, with no lid or covering on the container. The desiccant will begin to absorb moisture out of the atmosphere when exposed to an open environment. Therefore, the desiccant is already absorbing moisture from the facility’s atmosphere before it is ever placed inside the shipping container. Depending upon the humidity level inside the facility, the life and efficacy of the desiccant can be significantly compromised before it is placed in the shipping container. The simple solution to storing and handling desiccants properly is to keep the lid on the container of desiccants closed.

The careful placement of desiccant inside a shipping container is very crucial. First, it’s important that desiccant is NOT placed in contact with bare metal. As the desiccant begins to absorb moisture inside the package, it will draw the moisture to the surface of the metal. The higher moisture concentration at the point of contact with the metal will accelerate corrosion.

An effective, proven packaging design using VCI and desiccants for overseas shipments is to use 2 liner bags in the container with desiccants placed between the two bags. The inner bag liner, closest to the parts, needs to be VCI, and the outer bag liner can be plain poly. The desiccant placement between the two liner bags will reduce moisture inside the container without compromising the protection of the metal.

ZERUST®/EXCOR® offers a full line of corrosion inhibitor packaging and rust solutions. ZERUST® is the inventor of Volatile Corrosion Inhibitor (VCI) poly technology and offers expert on-site support in over 70 countries worldwide. For nearly 50 years, ZERUST® has helped customers reduce the cost and problems associated with corrosion. Have a challenging corrosion prevention need, such as overseas shipping or storage in corrosive environments? Trust ZERUST® to help you manage corrosion in your operations.