ZERUST® VCI Corrosion Solutions for the Military

The military frequently faces the challenge of corrosion, given that their equipment is often subjected to harsh conditions both in use and during storage. Consequently, without an effective method to inhibit corrosion, the equipment can become compromised, necessitating additional refurbishing costs and effort.

ZERUST®, boasting a wealth of experience, has carved a niche as a trusted name in the domain of corrosion prevention for the military. A significant number of ZERUST® VCI (Vapor Corrosion Inhibitors) and corrosion-inhibiting products not only meet Mil Specs but also carry NSN numbers, thereby bolstering our credibility. Furthermore, these products are extensively used by the armed forces, as evidenced by our CAGE number: 56758. This widespread usage underscores the effectiveness and reliability of ZERUST® products in providing top-tier corrosion protection.

VCI Military Solutions

Over the years, the military has consistently relied on Vapor Corrosion Inhibitors (VCIs) to shield metal equipment from corrosion. The application of these inhibitors serves a crucial purpose. Specifically, the use of VCIs in the military is driven by the need to protect metal equipment in harsh and challenging environments. Moreover, this practice aims to extend the life of the equipment, and ultimately, the overarching goal is to reduce maintenance costs.

How VCIs Work

VCIs operate in a unique way: they work by releasing a corrosion-inhibiting vapor into the surrounding environment. Upon release, the vapor forms strong bonds with a metal surface, promoting and maintaining the natural and healthy passive oxide layer on the metal. The VCI layer that forms is invisible, dry, and does not affect the physical properties or functionality of the metal in any way, effectively preventing the corrosion of metal. However, this protective layer isn’t permanent. In fact, it dissipates when the equipment is exposed to the environment (removed from the bag or enclosure), thus allowing the metal to be used, welded, painted, etc. Considering this dynamic nature, VCIs emerge as an ideal solution for military equipment, primarily because this equipment is often transported and stored in harsh environments.

Versatility and Effectiveness

VCIs are available in various forms. Firstly, they are available as paper, film, and emitters/diffusers. Not only can these be used to protect a wide range of metal equipment, but they also protect items such as firearms, ammunition, vehicles, and communications equipment. Furthermore, the use of VCIs in the military is on the rise. This increase is primarily due to the proven effectiveness of these products in preventing corrosion. Ultimately, their use extends the life of metal equipment, making them an invaluable resource in maintaining military gear.

Benefits of VCIs in the Military

One of the main benefits of VCIs is that they do not require special handling or maintenance. Particularly, this makes them an ideal solution for the military, where equipment is often handled by personnel with little training or expertise. Moreover, VCIs are also non-toxic and safe to use, thereby making them an attractive option for military personnel who need to protect their equipment in hazardous environments.

In addition to these benefits, VCIs are highly cost-effective. This is largely because, by protecting metal equipment from corrosion, VCIs can significantly extend the life of the equipment, reducing the need for repairs and replacements. Consequently, this can result in substantial cost savings for the military, as well as reduce the need for equipment to be taken out of service for maintenance.

Interestingly, VCIs are also very easy to use, further making them an ideal solution for the military. They can be easily integrated into existing storage and transport systems, and they can be readily applied to equipment in the field. This flexibility and convenience make VCIs a solution that can be adapted to a wide range of equipment and situations within the military.

Lastly, in addition to their cost-effectiveness and ease of use, VCIs are also environmentally friendly. Unlike other corrosion inhibitors, such as rust-preventative coatings, VCIs do not contain any harmful chemicals or solvents. This is particularly noteworthy as it makes VCIs an attractive option for the military, which is increasingly concerned about its environmental impact.

The Future of VCIs in the Military

In conclusion, the use of VCIs in the military is steadily increasing, largely due to their proven effectiveness in preventing corrosion and extending the life of metal equipment. On the financial side, VCIs are cost-effective. Moreover, they are easy to use. In terms of environmental considerations, they are also environmentally friendly, making them an ideal solution for the military. As time progresses, and as the military continues to search for efficient ways to protect its equipment and reduce maintenance costs, it becomes increasingly likely that the use of VCIs will continue to expand.

- ZERUST® Corrosion Solutions for the Military Brochure

- How to Use ZERUST® ICT® Weapon Protection Bags - For Extra-Large Equipment Bag

- How to Use ZERUST® ICT® Weapon Protection Bags - For Large Weapon Bag - Rifle Kit

- How to Use ZERUST® ICT® Weapon Protection Bags - For Small Weapon Bag - Handgun Kit

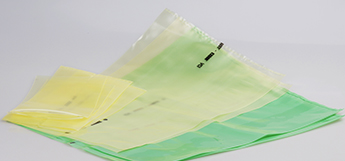

ZERUST® ICT®510-C VCI Military Anti-Rust Weapon Protection Bags are easy to use, lightweight, and high strength.

ZERUST® ICT®510-C VCI weapon bags are a proven solution for the military, primarily offering substantial protection for firearms and other metal equipment. Furthermore, these VCI bags, approved by the government, are designed to guard against rust and corrosion, thus extending the life of military weapons during storage and transport, even in harsh environments. Consequently, due to their effective and reliable results, ZERUST® VCI military bags have earned the trust of the armed forces.

Offering variety, the ZERUST® VCI military bags come in two different sizes. The small size is intended for safeguarding pistols and small accessories, while the larger size is designed specifically for rifles. Not only are these bags crafted using ZERUST® ICT®510-C ferrous film material, but they are also transparent, facilitating easy inspection. In conclusion, these bags provide a versatile and reliable solution for the protection of military equipment.

| Part Number | National Stock Number (NSN) | Dimensions x Thickness | Description | Quantity |

| 910-F-00006-KIT-100 | 6850-01-590-1665 | 14″ x 60″ x 6 MIL | Rifle, rubber bands & instructions | 100/Case |

| 910-F-00007-KIT-100 | TBD | 10″ x 18″ x 4 MIL | Handgun, rubber bands & instructions | 100/Case |

Supplement current corrosion-inhibiting methods by using ZERUST® VCI Military Vapor Capsules to protect the interior surfaces of your electronics.

ZERUST® Vapor Capsules are a highly effective and economical solution for protecting military equipment and electronics. The mechanism involves the release of a corrosion-inhibiting vapor that forms a thin, invisible layer on the metal surface. This process, in turn, prevents rust and corrosion. Notably, this method is greatly beneficial to the military, ensuring both the integrity and longevity of their assets.

In addition to this, ZERUST® VCI technology is approved and trusted by the government. Its distinctive capability to increase the lifespan of military systems under various conditions is remarkable. Regardless of being in storage or transport, VCI capsules offer reliable protection. They play a crucial role in safeguarding the armed forces’ equipment from harsh environments.

Lastly, applying ZERUST VCI military capsules leads to a significant increase in the operational readiness of military equipment. This crucial advantage contributes immensely to the overall effectiveness of the armed forces, underscoring the value of ZERUST VCI in military applications.

| Product Name / Part Number | National Stock Number (NSN) | Volume of Protection (Up to)‡ | Metal Protection | Quantity |

| VC1-1(s) / 375-M-00006 | 6850-01-426-3539 | 4 ft³‡ | Multimetal | 50/Case |

| VC1-1 / 375-M-00001 | 6850-01-338-1393 Prior: 4440-01-481-3150* |

4 ft³‡ | Multimetal | 50/Case |

| VC2-1 / 375-M-00002 | 6850-01-475-9949 Prior: 6850-01-345-7431* Prior: 4440-01-475-9949* |

35 ft³‡ | Multimetal | 25/Case |

| VC2-2 / 375-M-00003 | 6850-01-133-0373 | 35 ft³‡ | Multimetal | 10/Case |

| VC6-1 / 375-M-00004 | 6850-01-590-1676 | 900 ft³‡ | Multimetal | 4/Case |

| VC6-2 / 375-M-00005 | 6850-01-348-1090 Prior: 6850-01-348-1390* |

900 ft³‡ | Multimetal | 4/Case |

| ZAK-M22 / 375-M-00202 | N/A | 35 ft³‡ | Multimetal | 10/Case |

*Obsolete NSN

Reduce repair and maintenance costs by preventing corrosion within tubes, pipes, and gun barrels with the use of ZERUST® ICT® Tube Strips.

ZERUST® Tube Strips, a revolutionary product in the VCI military sector, certainly offer an effective solution for protecting military firearms and other pipes/tubes used in the field. These Tube Strips, uniquely infused with VCI, are strategically placed inside the tubes. Once inside, the VCI molecules act swiftly to form a protective layer on the internal metal surface of the tube/pipe, thus preventing rust and corrosion.

Notably, this method ensures the integrity and longevity of military assets, providing an economical and reliable solution for corrosion control. Further, ZERUST® Tube Strips are not only approved by the government but also tested rigorously to deliver the highest results in various environments.

In addition to being effective, they are also fast to apply, thereby increasing the management efficiency of army equipment. Ultimately, the use of ZERUST® tube strips extends the service life of military firearms and other metal systems. As a result, this leads to significant benefits for the armed forces, bolstering their readiness and capability on the field.

| Part Number | National Stock Number (NSN) | Volume of Protection (Up to)‡ | Metal Protection | Quantity |

|---|---|---|---|---|

| 475-F-00001 | 6850-01-590-1673 | 2″ (5 cm) diameter pipe‡ | Ferrous | 1000′ Roll |

ZERUST® Cor Tab® VCI Tablets ensure longevity and protection of military assets against corrosion.

ZERUST® Cor Tab® VCI Military Tablets offer a significant advantage in safeguarding military assets. Notably, these tablets provide effective corrosion control, thus ensuring the integrity and longevity of essential equipment. Additionally, when they’re strategically placed in storage or transport environments, they begin to release a vapor. This vapor consequently forms a protective layer on metal surfaces, effectively preventing rust and corrosion.

As a result, this economical solution significantly extends the life of metals, thereby leading to improved management efficiency. It’s noteworthy to mention that these tablets have received governmental approval for use, further testifying to ZERUST’s ability to deliver reliable results in asset protection.

Moreover, the successful application of VCI technology in the military sector stands as a testament to its efficacy and trustworthiness.

| Part Number | National Stock Number (NSN) | Tablet Size | Volume of Protection (Up to)‡ | Metal Protection | Quantity |

|---|---|---|---|---|---|

| 450-M-00001 | 6850-01-348-1092 | 0.25 gram | 0.25 ft³‡ | Multimetal | 600/bottle and 8 bottles/case |

| 450-M-00002 | 6850-01-349-7073 | 0.50 gram | 0.5 ft³‡ | Multimetal | 300/bottle and 8 bottles/case |

| 450-M-00003 | N/A | 1.00 gram | 1.0 ft³‡ | Multimetal | 150/bottle and 8 bottles/case |

Unleashing the power of ZERUST® Plastabs®: Transforming the landscape of VCI military asset protection and corrosion defense.

ZERUST® Plastabs®, a leading solution in VCI military asset protection, serves as an effective and economical method to prevent the corrosion of metals. Firstly, these plastic tabs release vapor corrosion inhibitors that form a protective layer on metal surfaces, thereby ensuring the integrity and longevity of military equipment. Furthermore, whether in storage or transport, ZERUST® Plastabs® provide the highest level of protection, even in challenging environments. In addition to this, their fast and easy application leads to increased control over asset management, consequently extending the service life of military assets. Finally, approved by the government and trusted by the army, ZERUST® Plastabs® significantly benefits the United States military’s corrosion prevention efforts.

ZERUST® Plastabs®, a leading solution in VCI military asset protection, serves as an effective and economical method to prevent the corrosion of metals. Firstly, these plastic tabs release vapor corrosion inhibitors that form a protective layer on metal surfaces, thereby ensuring the integrity and longevity of military equipment. Furthermore, whether in storage or transport, ZERUST® Plastabs® provide the highest level of protection, even in challenging environments. In addition to this, their fast and easy application leads to increased control over asset management, consequently extending the service life of military assets. Finally, approved by the government and trusted by the army, ZERUST® Plastabs® significantly benefits the United States military’s corrosion prevention efforts.

| Part Number | National Stock Number (NSN) | Size | Volume of Protection (Up to)‡ | Metal Protection | Quantity |

|---|---|---|---|---|---|

| 425-M-00001 | 6850-01-362-9256 | 1” x 1” | 0.4 ft³‡ | Multimetal | 1000/Package |

| 425-M-00002 | 6850-99-551-9054 | 0.75” x 0.75” | 0.2 ft³‡ | Multimetal | 1000/Package |

| 425-M-00003 | N/A | 0.50” x 0.50” | 0.1 ft³‡ | Multimetal | 1000/Package |

| 425-M-00004 | N/A | 0.75” x 0.75” (w/adhesive) | 0.2 ft³‡ | Multimetal | 1000/Package |

| 425-M-00010 | 6850-01-590-1667 | 1″ x 3″ (debossed) | 1.0 ft³‡ | Multimetal | 1000/Package |

Replace your current preservative lubricant grease with ZERUST® Axxanol™ Z-Maxx, reducing corrosion incidents and costs.

ZERUST® Axxanol™ Z-Maxx is a trusted military-grade grease. Primarily, it provides superior corrosion protection for military parts and components of machinery and equipment, even under extreme weather and salt-air conditions. Subsequently, when this grease coating is applied to metals, it forms a robust barrier against rust. As a result, it extends the lifespan of the equipment.

Interestingly, its economical and effective nature makes it a leading choice for military management. This is mainly because it outperforms most petroleum-based corrosion preventive coatings. Additionally, it is easier to apply and remove, thus saving on labor and maintenance costs.

Ultimately, the integrity and reliability of ZERUST® Axxanol™ Z-Maxx ensure the highest level of protection. Consequently, it plays a crucial role in safeguarding our military’s greatest assets.

| Part Number | Product | Indoor Protection Length (Up to)‡ | Outdoor Protection Length (Up to)‡ | Metal Protection | Quantity |

|---|---|---|---|---|---|

| 360-M-00001PL | Axxanol™ Z-MAXX | 3 years‡ | 1 year‡ | Multimetal | 5 Gallons |

| 360-M-00001DR | Axxanol™ Z-MAXX | 3 years‡ | 1 year‡ | Multimetal | 55 Gallons |

- Proven ZERUST®/EXCOR® corrosion protection

- Easy to use in the field

- Durable

- Economical to use

- Suitable for new equipment and to protect the reliability of existing equipment

- VCIs are also non-toxic and safe to use