Container Shipments

In industrial industries, container shipments are the most common way to transport metal parts and equipment overseas. This kind of transportation is so common because of its low cost, but it’s also the slowest form of transportation. During these long journeys, shipping containers are subject to extreme environmental variations such as temperature and relative humidity. With these variations, condensation forms along the inner walls of the shipment containers. This condensation will drip from the walls and ceiling onto the packages inside the container. In addition, if the metal parts are poorly packaged, humidity can enter the packaging and accelerate corrosion.

ZERUST® Z-CIS® Methodology

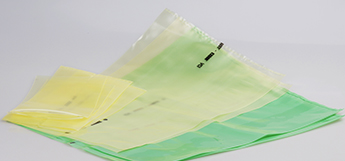

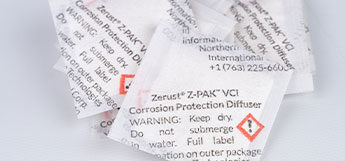

Using the ZERUST® Z-CIS® approach, our rust experts have the skills to design the right packaging solution to protect your parts. Our wide range of Contact Rust Preventative Coatings, Volatile Corrosion Inhibitor (VCI) Protective Packaging, and VCI Emitters provide the framework to develop a custom packaging solution to fit your needs.

Request InformationTypically, logistic companies hang large desiccants inside the container to absorb the condensation built up during transit. While the desiccants help absorb the container rain inside, they do not protect the metal parts inside of the shipment. Once a desiccant reaches its maximum life, it will no longer absorb condensation. Instead, it will release moisture back into the container and, even worse, drip onto the parts.

With the current pandemic affecting industries worldwide, container shipments take longer than ever before to reach their destination. They are frequently left in the port for weeks before they’re even loaded onto the cargo ships. So, the desiccants are reaching their maximum capacity more frequently and faster than ever, as they are subjected to salt water and moisture while waiting at the port. With the main benefit of container shipments being the cost savings, companies quickly learn these savings can evaporate when their parts arrive at their destination rusted and useless.

ZERUST® Vapor Corrosion Inhibitors (VCI)

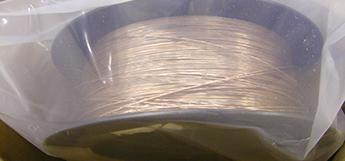

With the use of ZERUST® Vapor Corrosion Inhibitors (VCI) products, companies no longer have to rely on desiccants to absorb the moisture in the containers, as the compounds of ZERUST® VCIs release into the container airspace and actively prevent corrosion by forming strong bonds with the metal surfaces of the parts stored in the container promoting and maintaining the natural and healthy passive oxide layer on the metal. In addition, the VCI layer that forms is invisible and does not affect the physical properties or functionality of the metal in any way, allowing the metals to be painted, treated, and/or used straight out of the ZERUST® package without further cleaning.

- Effective corrosion protection and packaging combined in one step

- Metals are ready for use and assembly directly out of the packaging

- Suitable for new equipment and to protect the reliability of existing equipment.

- Available in many different formulations and sizes

- Provides safe and effective ZERUST® VCI protection

- Does not affect the circuit boards or electrical components.