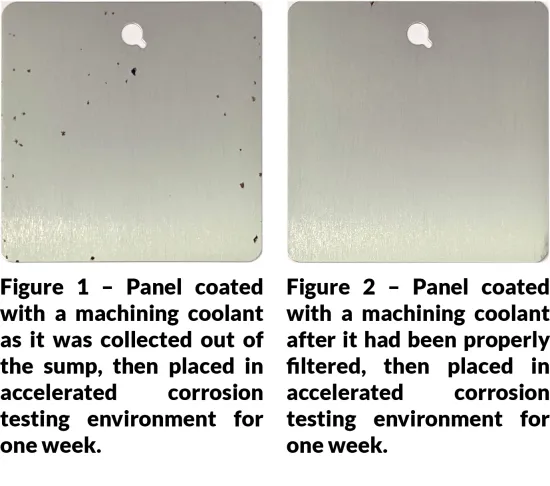

Cast metal surfaces coated with Axxanol™ 750 may potentially leave some brownish oil staining when exposed to hot, humid conditions and in direct contact with the PE bags. This is compared to Axxanol™ 758, which is a non-staining VCI oil, even when exposed to hot, humid conditions and in direct contact with the PE bags.

ZERUST® Axxanol™ 758 VCI Oil

ZERUST®/EXCOR® Axxanol™ 758 is a sprayable, non-staining rust preventative oil containing ZERUST® Intelligent Counter-Corrosion Technologies (ICT®), which consists of high-performance non-staining contact inhibitor with dual-action slow and fast release Vapor Corrosion Inhibitors (VCI). When shipped or stored in enclosed packaging, Axxanol™ 758 VCI Oil forms a clear, thin, oily film that provides a moisture barrier and contact inhibitor with ZERUST® VCI chemistry that migrates to metal surfaces in hard-to-reach voids, crevices, and chambers providing long-lasting corrosion protection.

Features

- Non-staining VCI oil

- All-in-one VCI, contact inhibitor, and barrier protection

- Sprayable rust prevention that is easy to remove

- Protects hard-to-reach voids, as well as chambers

- Multimetal protection

- Complies with Global Automotive Declarable Substance, TSCA, RoHS, and REACH SVHC requirements

Product Description

Use Axxanol™ 758 VCI Oil by spraying, misting, or fogging to protect metal components, machined and cast parts, engines, molds, and more for years‡ in applications using packaging. After application, we recommend packing the coated parts into ZERUST® VCI film for robust corrosion protection. As a result, the additional VCI molecules from the packaging complement the protection provided by Axxanol™ 758, with the VCI settling onto exposed metal surfaces inside the enclosure. Upon removal from the packaging, the VCI will dissipate from the metal surface, leaving behind a coating compatible with most engine oil lubricants. However, if the VCI oil coating needs to be removed for further processing, use a compatible ZERUST® AxxaWash™ product, commercial alkaline, or solvent cleaner. Furthermore, Axxanol™ 758 does not intentionally contain barium or heavy metals and complies with Global Automotive Declarable Substance, TSCA, RoHS, and REACH SVHC requirements.

Why Choose ZERUST®?

For over 50 years, beginning with the invention of Vapor Corrosion Inhibiting (VCI) film, ZERUST® has led the market in quality corrosion solution products. Furthermore, we dedicate ourselves to providing expert corrosion management services and further adding solutions for our customers. In addition, ZERUST® users have access to on-site support from ZERUST®/EXCOR® representatives in more than 70 countries. As a result, our customers have peace of mind when they choose ZERUST® for corrosion control management.

Resources

Availability

ZERUST®/EXCOR® Axxanol™ 758 VCI Oil is sold as a ready-to-use liquid product. For further ordering information, contact your ZERUST®/EXCOR® representative.

| Part Number | Quantity | Protection | |

|---|---|---|---|

| 350-M-00107PL | 5 Gallons | Multimetal | |

| 350-M-00107DR | 55 Gallons | Multimetal |