What is the concentration effect? We have all seen the concentration effect occur in our daily lives. With a kitchen sink full of soapy water used to wash dishes, the more dishes you wash in the water, the dirtier the water gets, and the less effective it becomes at cleaning dishes. As the water in the sink is used more times, the concentration of soap in the water decreases as it is used to clean dishes, and the concentration of contamination increases as dirt, oil, and food scraps are washed off the dishes. This buildup of contamination, coupled with the selective depletion of beneficial chemistry in a fluid, is the heart of the concentration effect.

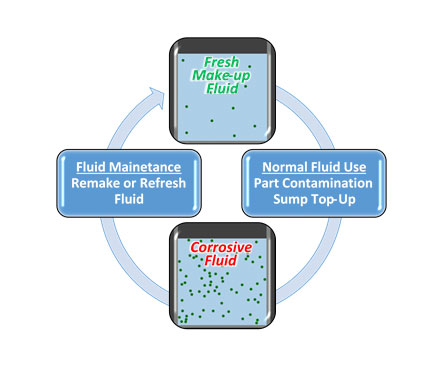

How does the concentration-effect change metalworking fluids? The concentration effect is the leading cause of the build-up of dangerous and corrosive contamination in metalworking fluids. Metalworking fluids, especially those that are diluted with water before use, are extremely susceptible to the concentration effect. Many metalworking fluids are formulated to be able to handle a certain amount of contamination, however, if the fluid isn’t maintained well enough, the corrosive contamination can begin to overpower the beneficial chemistry. Once the concentration-effect has occurred in a fluid, your metal components will be at risk for corrosion. Lubricants will leave corrosive residues on parts, wash fluids will not effectively clean parts, and rust preventatives will not effectively protect parts.

How can the concentration-effect be avoided? By using high-quality water (deionized or reverse osmosis water), the initial ionic contamination in the metalworking fluid can be avoided, and when make-up fluid is added because of evaporation and drag-out losses, no extra corrosive ionic contamination is added. Additionally, whenever a sump or central fluid reservoir is topped off or refilled, straight water should never be used – instead, a low concentration of the metalworking fluid should be added. This helps ensure any beneficial chemistry in the fluid that is naturally consumed during the fluid’s life cycle is replenished when the fluid is topped off. Finally, frequent fluid analysis, maintenance, and logs can minimize significant changes in fluid quality over time.