Washes, rinses, machining coolants, lubricants, rust preventatives, and other metalworking fluids (MWFs) are frequently used in industrial manufacturing facilities. Proper maintenance of metalworking fluids is required to preserve the fluid’s health, increase the fluid’s lifetime, minimize corrosion risk, and even reduce wear and tear on tools and machines. Unfortunately, proper filtration is one of the more accessible aspects of metalworking fluids maintenance that is often forgotten about or overlooked.

A large variety of particulate contamination can get into metalworking fluids through regular use. Dirt, dust, fibers, plastic shavings, and metal fines or swarf are just some of the particulate matter that can contaminate fluids, causing a wide variety of issues:

- Clogged/damaged spray nozzles

- Quickly consumed corrosion inhibiting chemistry in metalworking fluids

- Damage to critical surfaces with tight tolerances

- Corrosion risk from the increased time of wetness and galvanic effects

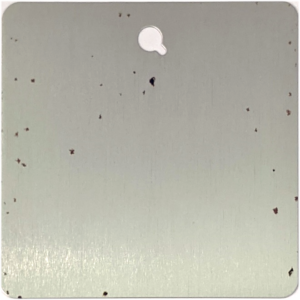

A poorly maintained machining coolant sample was collected to demonstrate the impact proper corrosion filtration can have. A portion of this fluid was then properly filtered to remove any particulate contamination present in the sample. One panel was coated in the dirty fluid, and one panel was coated in the filtered fluid. After a week in an accelerated corrosion testing environment (IEC 60068-2-30), the difference is clear – proper metalworking fluid filtration can help reduce corrosion!

|

|

|

If your manufacturing facility is struggling with corrosion issues, ZERUST® can help! We analyze the current state of your corrosion management needs and work with you and your team to implement the best and most cost-effective solution. ZERUST® can come to your facility and do a step-by-step analysis of your current process, including fluid audits, VCI and packaging process audits, and data logger analysis. Our mission is to provide you with the right products, processes, and procedures to ensure that you can achieve your desired results.