How VCI Protection Activates Inside Packaging

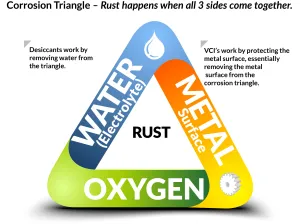

VCI packaging releases corrosion-inhibiting molecules that spread throughout the enclosed space once users seal the metal parts inside.. Furthermore, these molecules bond to the metal surfaces, creating a microscopic protective layer. This layer interrupts the electrochemical reactions that cause rust and corrosion, even in humid or fluctuating environments, providing insights into how VCI works.

A sealed enclosure maintains the vapor concentration, and opening the packaging allows the VCI molecules to safely dissipate into the air without leaving residue. This illustrates the full cycle of how VCI’s protective process functions.

Types of Vapor Corrosion Inhibitor Products

VCI technology comes in multiple formats, allowing users to tailor corrosion protection to specific applications, package sizes, and handling requirements. Understanding VCI’s versatility in different formats is crucial to grasping how it works in varying environments and applications.

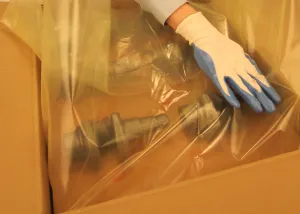

Vapor Corrosion Inhibitor Films

VCI Packaging Films incorporate corrosion-inhibiting compounds directly into polyethylene film. These films continuously release VCI molecules inside sealed bags, liners, or wraps. They are commonly used for parts, pallets, export shipments, and long-term storage. VCI films protect ferrous, non-ferrous, or multimetal assemblies while maintaining clean, dry surfaces. By knowing this, you can understand how VCI films work to safeguard diverse metal types.

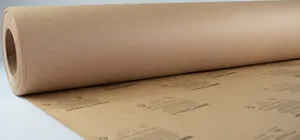

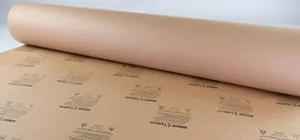

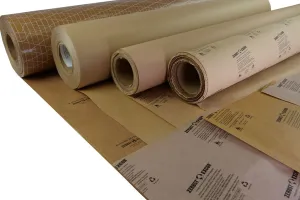

Vapor Corrosion Inhibitor Packaging Paper

Vapor Corrosion Inhibitor Packaging Paper

VCI Kraft Packaging Paper provides corrosion protection through direct contact and vapor-phase action. The paper emits VCI molecules into the surrounding airspace while also separating metal surfaces to prevent abrasion. It is frequently used for interleaving, wrapping individual components, lining boxes, or protecting machined parts during storage and transit. Recognizing this function helps us understand how VCI operates to prevent corrosion in challenging conditions.

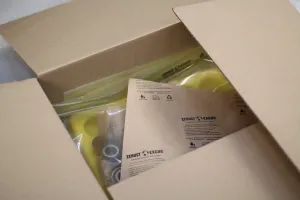

Vapor Corrosion Inhibitor Emitters and VCI Diffusers

Vapor Corrosion Inhibitor Emitters and VCI Diffusers

VCI Emitters & Diffusers deliver corrosion protection in larger or hard-to-seal enclosures where films or paper are impractical. These devices release a controlled amount of VCI vapor into cabinets, electrical enclosures, control panels, void spaces, and equipment housings. They are especially effective for protecting internal surfaces and complex assemblies without direct contact, demonstrating how VCI functions in unique settings.

Our corrosion experts can help you select the best VCI solution based on your metals, environment, and storage or shipping needs.

What Metals Does VCI Protect?

VCI technology is formulated to protect a wide range of metals, including carbon steel, cast iron, aluminum, copper, brass, bronze, and other common alloys. In addition, Multimetal VCI formulations are designed to prevent corrosion in assemblies containing dissimilar metals, making them suitable for automotive, industrial, aerospace, and export packaging applications. Understanding the metals VCI protects answers the question of how VCI can work across different metal types.

Why Vapor Corrosion Inhibitors Leave No Residue

Because VCI protection relies on vapor-phase chemistry rather than physical coatings, it does not build up on the metal surface. The molecular layer is self-renewing inside sealed packaging and completely dissipates once the enclosure is opened. Consequently, this is why VCI-protected parts remain clean and ready for immediate use, reducing labor, rework, and downstream processing costs. A residue-free usage illustrates how VCI works efficiently.

Why Choose VCI Instead of Traditional Rust Preventatives?

Traditional corrosion protection methods often require manual application and removal, adding time, cost, and waste. VCI packaging works passively once installed, protecting metal surfaces throughout storage and shipment. By eliminating cleaning steps and reducing corrosion-related failures, VCI technology supports more efficient, reliable, and scalable corrosion prevention programs. This consideration shows why understanding how VCI works provides advantages over traditional methods.

Contact ZERUST® to get expert guidance on vapor corrosion inhibitor packaging, emitters, and rust prevention solutions.