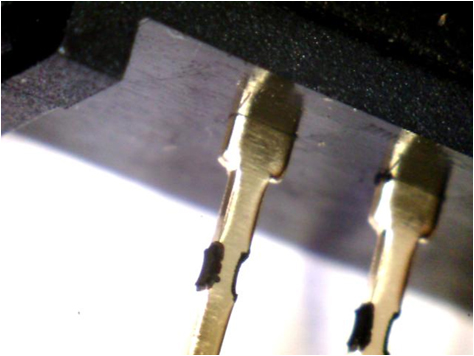

Who?

OEM parts and service supplier

What?

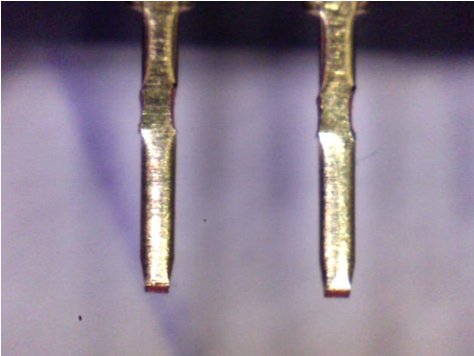

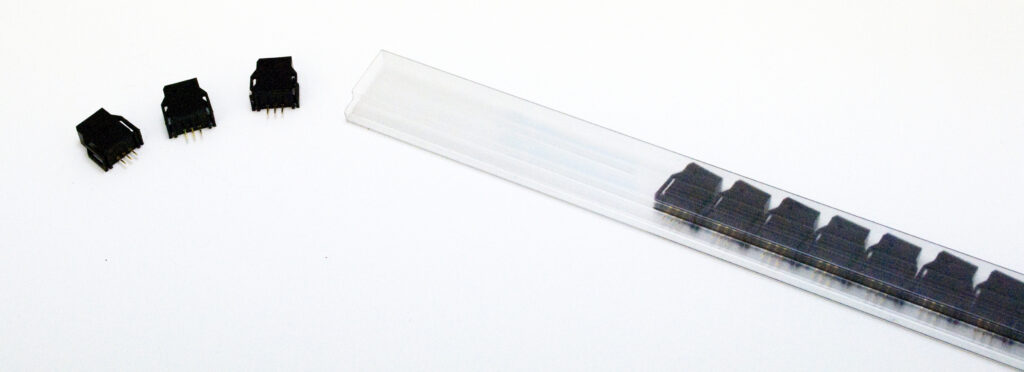

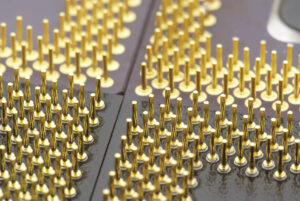

Recovery of tarnished sensors and protection from future corrosion

Why?

Restore sensors to fulfill warranty replacement part orders

How?

ZERUST® custom cleaned the sensors and protected them from future tarnish with ICT®520-CB1 Anti-Tarnish VCI Film