Corrosion protection in shipbuilding is a critical part of ensuring vessel integrity, safety, and operational efficiency. From steel hulls to electrical enclosures, components are constantly exposed to harsh conditions, including salt-laden air, humidity, and temperature fluctuations. Consequently, these parts face a high risk of corrosion.

Corrosion protection in shipbuilding is a critical part of ensuring vessel integrity, safety, and operational efficiency. From steel hulls to electrical enclosures, components are constantly exposed to harsh conditions, including salt-laden air, humidity, and temperature fluctuations. Consequently, these parts face a high risk of corrosion.

To meet these challenges, modern shipbuilders rely on a combination of solutions to achieve effective corrosion protection in shipbuilding, including protective coatings, greases, Vapor Corrosion Inhibitor (VCI) packaging and emitters, and cleaners/degreasers, all utilized in modern shipbuilding. However, no single solution fits every application. Instead, a layered, system-based approach offers the most reliable and cost-effective protection across fabrication, storage, transport, and maintenance.

Understanding the Risks of Corrosion in Shipbuilding

Corrosion is more than a cosmetic issue. As a result, it compromises the structural integrity of vessels, shortens equipment lifespan, and leads to extensive maintenance costs. Therefore, in an industry where downtime and delays are costly, proactive corrosion control is essential.

For example, common areas prone to corrosion include:

- Ballast tanks and enclosed void spaces

- Piping systems, heat exchangers, and condensers

- Engine assemblies, gearboxes, and bearings

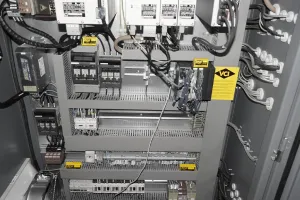

- Electrical panels and connectors

- Steel components in outdoor storage or international transit

Whether shipbuilders are constructing commercial cargo vessels, naval ships, or offshore platforms, they must protect critical assets from corrosion at every stage.

Advanced Corrosion Protection Methods Used in Modern Shipbuilding

To address these challenges, ZERUST® offers a comprehensive portfolio of corrosion solutions that support integrated protection strategies across all phases of the shipbuilding process:

1. VCI Products for Corrosion Protection in Shipbuilding

VCIs release protective molecules that bond to metal surfaces. As a result, it forms an invisible shield that prevents corrosion. Moreover, these products are ideal for enclosed or hard-to-reach areas and are especially effective during storage and global shipping.

Key VCI products:

|

VCI Films, Bags, and Tubing: Used to wrap large metal components and assemblies. |

|

VCI Emitters and Capsules: Designed for electrical boxes, void spaces, and control panels. |

|

VCI Paper: Ideal for packaging smaller metal parts. |

Benefits:

- Non-residue protection

- No surface cleaning required after use

- Effective in enclosed spaces and during transit

2. Rust Preventative Coatings and Oils

Specifically, for components that require durable, long-term protection, ZERUST® rust-preventative coatings and oils offer flexible options tailored to application conditions.

Key product lines:

|

Axxanol™ Rust Preventative Series: Light- to heavy-duty oils that protect internal components, engine parts, or items in storage. |

|

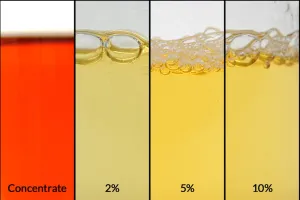

Axxatec™ Water-Based Inhibitors: Ideal for spray or fog applications, often used in tanks or closed-loop systems. |

|

Axxanol™ Grease-Based Coatings: Provide long-lasting protection for parts exposed to severe marine environments. |

Additionally, these coatings offer the flexibility required for corrosion protection in shipbuilding, with varied film thicknesses and surface finishes, and are easily removed prior to assembly or use.

3. Corrosion Inhibitor Tapes and Weld Joint Protection

In many cases, shipbuilding involves prolonged exposure of unfinished or temporarily joined metal sections. As a solution, ZERUST® provides Corrosion-Inhibiting Tapes to shield these vulnerable areas.

|

Corrosion-Inhibiting Tapes: Applied to weld seams or flanges to prevent rust. |

4. Surface Cleaners and Rust Removers

Before applying coatings or assembling components, thorough surface preparation is essential. Otherwise, protective products may fail to perform as intended. As a result, ZERUST® offers a full line of corrosion removers and degreasers that address various levels of rust severity and contamination.

|

AxxaClean™ ICT®625-RR: pH-neutral, acid-free chelating rust remover for recovering mildly to moderately rusted parts. |

|

AxxaClean™ 2048: Moderate-acting, non-hazardous rust remover designed to eliminate medium rust and tarnish, even in the most hard-to-reach cracks and crevices. |

|

AxxaClean™ 3048: Rapid-acting industrial rust remover designed to eliminate heavy corrosion and tarnish, even in the most hard-to-reach cracks and crevices. |

|

AxxaWash™ Industrial Cleaners & Degreasers: Effective surface prep solutions that remove oils and contaminants prior to applying rust preventatives. |

As a result, this supports a full-cycle corrosion control program from cleaning to protection.

5. Building Personalized Corrosion Protection Systems with Z-CIS®

Every shipbuilding environment presents unique corrosion challenges, driven by factors like humidity, temperature variation, material combinations, and exposure during transit or lay-up. Therefore, to address these complexities, ZERUST® offers a personalized, data-driven approach through its Z-CIS® (ZERUST® Corrosion Inhibiting System) methodology.

Z-CIS® enables shipbuilders to:

- Identify root causes of corrosion across their operational workflow

- Select optimal combinations of VCI, coatings, packaging, and surface prep products

- Validate protection performance through real-world testing and environmental monitoring

- Implement efficient and scalable corrosion management programs tailored to vessel type and location

This comprehensive system approach ensures every corrosion protection plan is engineered with precision, delivering maximum asset protection, reduced downtime, and long-term cost savings.

How ZERUST® Supports Corrosion Protection in Shipbuilding Applications

To support long-term vessel reliability, shipbuilders can implement ZERUST® products at key stages, such as:

- During fabrication: Apply rust inhibitors on partially completed sections.

- In modular construction: Wrap and ship blocks using VCI films and interior emitters.

- Pre-installation: Use protective oils or coatings on mechanical assemblies and engines.

- During lay-up or long-term storage: Fog closed systems with water-based inhibitors or VCI powders.

- For spares and consumables: Store parts in VCI bags.

Benefits of a Multi-Layered Corrosion Strategy

Therefore, by combining product categories, rather than relying on a single approach, shipbuilders gain:

- Comprehensive protection across multiple metals and exposure scenarios

- Faster commissioning and reduced downtime

- Cleaner work environments and less labor-intensive maintenance

- Lower total lifecycle cost of ship components

- Support for sustainability and regulatory compliance

Building with Confidence

Indeed, the stakes are high in shipbuilding. Ultimately, corrosion can compromise safety, delay schedules, and increase operational costs. That’s why leading shipbuilders are turning to advanced corrosion protection methods used in modern shipbuilding, leveraging everything from VCI and rust-preventative coatings to packaging and cleaning solutions.

Indeed, the stakes are high in shipbuilding. Ultimately, corrosion can compromise safety, delay schedules, and increase operational costs. That’s why leading shipbuilders are turning to advanced corrosion protection methods used in modern shipbuilding, leveraging everything from VCI and rust-preventative coatings to packaging and cleaning solutions.

For this reason, ZERUST® delivers a complete suite of corrosion control products, engineered to support shipbuilding operations from fabrication to deployment. Whether protecting an electrical panel or an entire engine block, our solutions are trusted worldwide for performance, reliability, and efficiency.

Need help designing a corrosion protection plan for your shipyard or manufacturing facility?

Contact ZERUST®/EXCOR® today to explore a tailored strategy that fits your shipbuilding workflow and environment.