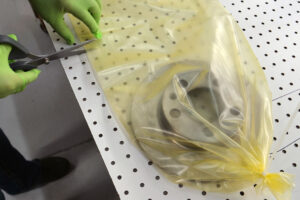

VCI stands for Volatile or Vapor Corrosion Inhibitors. ZERUST® applies VCI technology to inhibit corrosion on metal surfaces. VCI film is packaging that generally consists of polyethylene film that has been impregnated with chemical formulations that are unique to each manufacturer. While the underlying formulations can vary significantly, the finished products function similarly in that they release very low concentrations (typically in parts per ten-thousandth) of invisible corrosion inhibiting vapors into the surrounding air. The vapor molecules subsequently condense onto exposed metal surfaces and form a molecular corrosion shield that can protect against rust and other forms of corrosion for many years. Typical service life is up to three (3) years and even longer in some cases. When the VCI packaging is later removed, all vapor corrosion inhibiting molecules rapidly evaporate. This leaves the metal parts clean and ready for immediate use.

ZERUST® ICT®510-PCR30 Post-Consumer Recycled (PCR) VCI Film

ZERUST®/EXCOR® ICT®510-PCR30 Post-Consumer Recycled (PCR) VCI Film is a 30% recycled polyethylene film containing proven ZERUST® Vapor Corrosion Inhibitors (VCI). As a result, providing sustainable and versatile protection against corrosion damage for metals in shipping, in addition to storage.

Features

- Made with 30% post-consumer recycled polyethylene VCI film

- Effective corrosion protection, as well as packaging combined in one step

- Metals are ready for use, as well as assembly directly out of the packaging

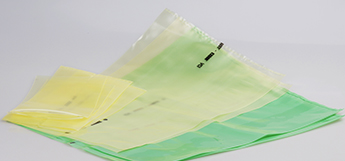

- Available in many different sizes and options to ensure optimal protection

- Provides safe and effective ZERUST® VCI protection, further enhancing product reliability

- Recyclable

Product Description

ZERUST®/EXCOR® ICT®510-PCR30 Post-Consumer Recycled (PCR) VCI Film – Advanced Corrosion Protection

The process of post-consumer recycling involves collecting, processing (sorting, washing, grinding, extruding), and reusing materials and products that consumers have used and then discarded. As a result, this approach is vital for reducing waste, conserving resources, and limiting the environmental impact of traditional disposal methods like landfills and incineration. Furthermore, use ZERUST® ICT®510-PCR30 Post Consumer Recycled (PCR) VCI Film to protect metal components and assemblies, cast parts, and more for years‡. Additionally, for added protection in challenging environments, ZERUST® VCI Film may be used with ZERUST® corrosion inhibitor liquid RPs and VCI emitter products. Lastly, ICT®510-PCR30 VCI Film comes in a formulation that offers protection against ferrous materials and is available in VCI bags, gusset liners, tote covers, and other packaging solutions to provide optimal protection.

Carbon Savings

Replacing 100 metric tons (100,000 kg) of conventional polyethylene plastic VCI packaging with ICT®510-PCR30 results in a remarkable carbon reduction of 26,000 kg (57,320 lbs.). Consequently, this achievement is equivalent to*:

|

|

|

|

| 95-ton reduction in CO2 emissions for every 100 metric tons. | CO2 emissions reduction is equivalent to 21 cars driven annually for every 100 metric tons. | Reduction in CO2 emissions equivalent to the consumption of 10,727 Liters of gasoline for every 100 metric tons. | Reduction in CO2 emissions equivalent to the carbon sequestered by 1,576 tree seedlings grown for 10 years for every 100 tons. |

*WARN MODEL. Source: US EPA Greenhouse Gas Equivalencies Calculator (as of February 2024).

Why Choose ZERUST®?

As a leader in corrosion prevention and rust protection solutions, ZERUST® recognizes the importance of environmental responsibility and has taken significant steps to implement post-consumer recycling technology across our VCI poly solutions. As a result, ZERUST® VCI film has proven its performance with customers worldwide for over 50 years. In addition, our PCR VCI Film offers exceptional rust prevention for industries such as automotive, agricultural, aerospace, and mining. Furthermore, ZERUST®/EXCOR® offers on-site support and service in more than 70 countries via a network of 21 JV partnerships. Check with your ZERUST®/EXCOR® representative for a comprehensive corrosion management solution that is most effective for your metal assets.

Availability

ZERUST®/EXCOR® ICT®510-PCR30 post-consumer recycled (PCR) VCI Film is a made to order product available upon request with many options, subject to minimum order quantities. Furthermore, contact your ZERUST®/EXCOR® representative for ordering information.

Sizes and Mil Options:

| Thickness range: 2 – 6 mil. |

|

| Size ranges for 2 – 4 mil (width): Bags & Perforated Tubing: 4” – 88” (flat) 8” – 136” (gusset) Tubing (Non-Perforated): 4” – 100” (flat) Sheeting: 8” – 100” (single wound sheeting) 101” – 22’ (must be folded, e.g., centerfold) |

Size ranges for 5 – 6 mil (width): Bags & Perforated Tubing: 4” – 88” (flat) 8” – 120” (gusset) Tubing (Non-Perforated): 4” – 100” (flat) Sheeting: 8” – 100” (single wound sheeting) 101” – 20’ (must be folded, e.g., centerfold) |

| Part Number | |

|---|---|

| Custom Order |