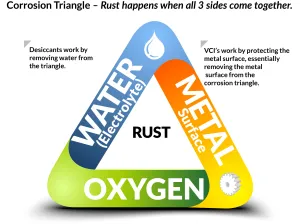

Correctly sealing VCI packaging is critical to achieving maximum corrosion protection. The tighter and more complete the seal, the more effectively the vapor corrosion inhibitor chemistry remains concentrated around the metal surface. This enclosed environment allows ZERUST® VCI molecules to continuously protect exposed metal from corrosion.

Proper sealing does not require vacuuming out air. Instead, the goal is to minimize air exchange and prevent water intrusion while maintaining a stable, enclosed space for vapor-phase protection.

Why sealing matters when asking how do you correctly seal VCI packaging

When learning how do you correctly seal VCI packaging, it is important to understand how VCI technology works. ZERUST® VCI molecules vaporize inside the enclosure and adsorb onto metal surfaces, forming an invisible corrosion-inhibiting layer.

If the package is loosely sealed, outside air, humidity, and contaminants can enter. This reduces VCI concentration and weakens corrosion protection. A well-sealed package keeps the protective atmosphere intact throughout storage or shipment.

How do you correctly seal VCI packaging using common closure methods

Several closure methods can be used effectively when sealing VCI packaging, depending on the application and packaging material.

Folding and taping

A simple and reliable method is to fold the VCI film or bag opening over itself and secure it tightly with packaging tape. This method reduces air exchange and helps block moisture entry.

Staples with tape coverage

Staples can be used to close VCI bags or films. When stapling, always apply tape over the staple holes. This step is essential to prevent air and moisture from entering through the punctures.

Zip ties or banding

Zip ties or banding can be used for larger packages or bundled components. After cinching the closure, fold excess film inward and tape it down to reduce airflow.

Heat sealing for maximum protection

Heat sealing provides the most airtight closure and delivers the highest level of corrosion protection. While heat sealing is not required for most applications, it is recommended for long-term storage, export shipments, or highly humid environments.

How do you correctly seal VCI packaging without removing air

It is not necessary to extract air from VCI packaging before sealing. Removing air does not improve corrosion protection and may even cause unnecessary handling issues.

Instead, focus on:

- Creating a tight, continuous seal

- Minimizing openings and gaps

- Preventing external airflow

VCI technology works effectively in the presence of air as long as the enclosure remains sealed.

Learn how to correctly use ZERUST® VCI products

Explore best practices for sealing, handling, and applying ZERUST® VCI packaging to achieve reliable corrosion protection in real-world conditions.

How do you correctly seal VCI packaging to prevent water intrusion

Water intrusion is one of the most common causes of corrosion inside otherwise protected packages. When sealing VCI packaging, always ensure water cannot pool or penetrate the enclosure.

Best practices include:

- Folding film openings downward to shed water

- Fully closing VCI gusset bags so water cannot collect in corners

- Avoiding upward-facing folds or openings

- Keeping sealed packages off wet floors or standing water

Preventing liquid water entry is just as important as minimizing air exchange.

Common mistakes to avoid when learning how do you correctly seal VCI packaging

Avoid these frequent sealing errors that can compromise corrosion protection:

- Leaving gaps or loose folds in the seal

- Failing to tape over staple holes

- Allowing water to pool on top of sealed bags

- Packaging wet or condensation-covered parts

- Reopening packages unnecessarily during storage

Each of these mistakes reduces VCI effectiveness and increases corrosion risk.

Best practices checklist for how do you correctly seal VCI packaging

Use this checklist to ensure consistent results:

- Ensure parts are clean and visibly dry before packaging

- Fully enclose parts with ZERUST® VCI film, bags, or paper

- Fold openings tightly and secure with tape, staples with tape, or heat seals

- Seal all punctures, seams, and closures

- Store packages in a way that prevents water exposure

Following these steps helps maintain a stable corrosion-inhibiting environment throughout storage and shipment.

Need help selecting the right VCI packaging system?

If you have questions about how do you correctly seal VCI packaging for your specific application, ZERUST® technical experts can help design a system-based solution. Proper sealing, combined with the right VCI materials, ensures reliable corrosion protection in real-world conditions.

Need help sealing VCI packaging correctly?

ZERUST® corrosion experts can help you select the right VCI packaging system and sealing method to protect your metal parts during storage and shipment.