Problem

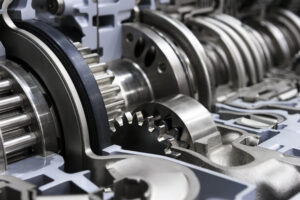

A large steel roll supplier that recently shut down their facility contacted ZERUST®, as they were looking for a corrosion control company to assist with preserving their assets. In addition, they were looking to protect these assets in case the facility opens again or should they need to transfer equipment to their other plants across the US. They were concerned about preserving the working and backup rolls, large gearboxes, and electrical boxes along the manufacturing line.

Solution

A local ZERUST® representative visited the customer’s facility to inspect further the assets they were looking to preserve and find the best solution for each application. After analyzing the facility and discussing it with upper management, it was determined that Axxanol™ 707C would provide the best solution to protect the large gearboxes as 707C’s volatile corrosion inhibitors (VCI) migrate to protect hard-to-reach internal surfaces of the gearbox for up to 2 years‡ from rust and corrosion.

The working and backup rolls would be protected by Axxanol™ Z-Maxx LV corrosion preventative grease in conjunction with large ICT®510-C VCI volatile corrosion inhibitor bags. Axxanol™ Z-Maxx LV provides an easy-to-use rust preventative grease that protects against rust and corrosion for up to 3 years‡. The customer was concerned that a corrosion prevention grease would be difficult to remove when they were back in service. However, Z-Maxx™ LV allows easy removal with an alkaline cleaner when the rollers are back up and running.

Lastly, ZERUST® VC6-2 Vapor Capsule diffusers provided the perfect solution for the electrical boxes along the manufacturing line, as the Vapor Capsules also contain patented ZERUST® VCI technology that protects metal from rust in hard-to-reach areas of control panels, electrical cabinets, and other enclosed spaces, even when they are in operation for up to 2 years‡.