Who?

What?

Corrosion prevention for CKD shipments

Why?

Low-cost packaging film failed to protect parts

How?

Switching to ZERUST® ICT®510-C VCI Film saved $200,000 per month in corrosion costs

Corrosion prevention for CKD shipments

Low-cost packaging film failed to protect parts

Switching to ZERUST® ICT®510-C VCI Film saved $200,000 per month in corrosion costs

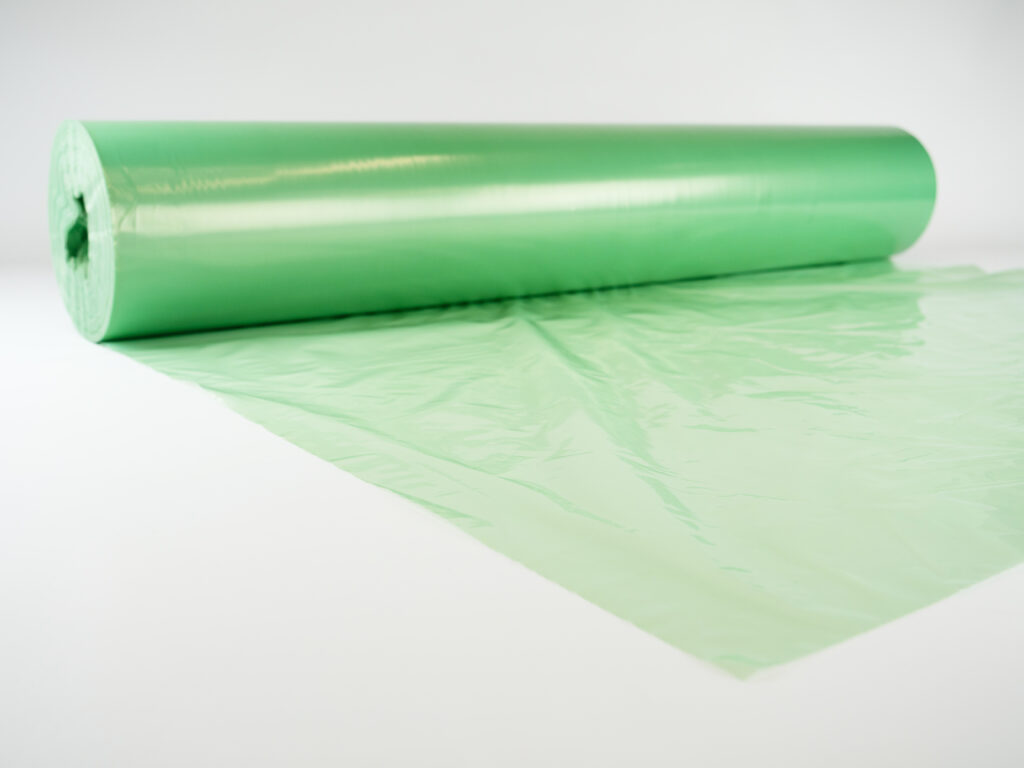

When a major international automobile manufacturer switched to a cheaper corrosion-inhibiting solution for overseas CKD shipments, it didn’t anticipate the cost-cutting decision to cause a negative effect on its bottom line. Prior to reducing spending, the company used ZERUST® VCI corrosion-inhibiting packaging film and had no corrosion problems. However, soon after switching to a generic product, the company learned the true costs of preventable corrosion. It wasn’t long before complaints of corrosion were reported by customer plants in the US. While promoted as “similar” to ZERUST® VCI film, the lower-cost corrosion-inhibiting products performed less effectively than plain polyethylene packaging that contained no corrosion inhibitors! Complaints and part replacements cost the company over $200,000 USD—with no end in sight.

The company decided to reevaluate ZERUST® products and used ZERUST® ICT®510-C Ferrous and Multimetal VCI Film to protect shipments. Parts packaged with the ZERUST® VCI film arrived in good condition with no corrosion—even in critical areas, such as welding points. The auto manufacturer decided to change back to using only ZERUST® corrosion-inhibiting products. Corrosion complaints decreased significantly, and the manufacturer learned the actual bottom-line value of proven corrosion control.

Automotive parts protection from rust & corrosion

For years‡

Amount saved by switching to ZERUST®

Over $200,000 a month

Customer Satisfaction

100%

The customer has been pleased with their corrosion-free results and now relies on ZERUST® for all their work-in-process, storage, and shipping VCI needs for their facilities across the US. Contact a ZERUST® Representative for a comprehensive corrosion management solution most effective for your metal assets.