During seasonal shutdowns or equipment lay-up, exposed metal surfaces are at increased risk of corrosion from moisture, contaminants, and temperature fluctuations. Selecting the right lay-up rust preventative is critical. This ensures equipment remains protected and ready for a smooth return to service. The ideal solution depends on equipment type and lay-up duration. It also depends on environmental exposure, such as humidity, salt air, or outdoor storage.

ZERUST® offers a comprehensive range of lay-up rust preventative coatings and Vapor Corrosion Inhibitor technologies engineered specifically for idle equipment, seasonal shutdowns, and long-term lay-up conditions.

Explore ZERUST® Corrosion Protection Products

Find the right lay-up rust preventative coatings, VCI solutions, and corrosion protection systems for your equipment.

How does a lay-up rust preventative protect idle equipment?

A lay-up rust preventative works by forming a protective barrier that interrupts the corrosion process before rust can form. Depending on the formulation, this protection may occur through surface contact barriers, vapor-phase migration, or a combination of both. Selecting the proper approach helps protect both exposed and hard-to-reach metal surfaces during extended idle periods.

Lay-up rust preventative coatings for external metal surfaces

For most lay-up applications, rust preventative coatings provide the first line of defense. These coatings shield exposed metal from moisture, oxygen, and contaminants that drive corrosion during shutdowns.

VCI coatings for internal surfaces

Coatings containing Vapor Corrosion Inhibitors, such as ZERUST® Axxanol™ 750 and ZERUST® Axxanol™ 758, release corrosion-inhibiting molecules that form an invisible protective layer on metal surfaces. This vapor-phase protection is especially effective for internal cavities, crevices, and enclosed geometries that are difficult to coat directly.

Oil-based lay-up coatings

For accessible components such as shafts, bearings, flanges, and machined surfaces, oil-based lay-up rust preventative coatings, including Axxanol™ 33, 46-Bio, A35-30, and A35-8030, create a thin oil film that repels moisture. These products can deliver protection lasting up to several years‡, depending on environmental conditions.

Grease-based coatings for severe environments

In severe environments such as high humidity, outdoor storage, or coastal exposure, grease-based lay-up rust preventative options like Axxanol™ Spray-G and Z-Maxx provide a thicker, more durable barrier. These coatings resist wash-off, withstand long-term exposure, and can still be removed efficiently before equipment returns to service.

Lay-up rust preventative solutions for enclosed equipment and electronics

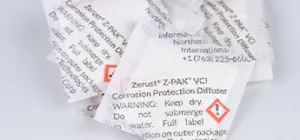

For enclosed systems such as control panels and electrical housings, corrosion protection can be enhanced using vapor-phase technologies. ZERUST® VCI emitters, including Vapor Capsules, ActivPak®, and Z-PAK®, continuously release corrosion-inhibiting vapors that migrate throughout the enclosure, protecting all internal metal surfaces.

Moisture control for lay-up rust preventative systems

To manage moisture during lay-up, ZERUST® ActivDri™ PWA packets combine desiccant action with VCI protection. This dual-action approach helps prevent condensation and corrosion. It also helps prevent electrical failures during idle periods caused by temperature cycling.

Learn More About ZERUST® Moisture Control Solutions

Explore how ZERUST® ActivDri™ moisture control products help prevent condensation, corrosion, and electrical issues during lay-up and seasonal shutdowns.

Surface preparation for effective protection

Proper surface preparation is essential for maximizing the effectiveness of any lay-up rust preventative. Before application, metal surfaces should be cleaned to remove dirt, process oils, salts, and existing residues. Surfaces must then be thoroughly dried. This step is necessary to eliminate trapped moisture that could undermine corrosion protection.

Lay-up rust preventative coatings can be applied by spray, brush, or dip, depending on part size and geometry. When equipment is ready to return to service, most ZERUST® rust preventative coatings can be removed using ZERUST® AxxaWash™ industrial cleaners. Alternatively, use commercial alkaline washes or approved solvent-based cleaning systems.

A complete system for seasonal shutdowns

By combining Axxanol™ lay-up rust preventative coatings, VCI emitter technologies, moisture control solutions, and proper surface preparation, ZERUST® delivers a complete corrosion protection system for seasonal shutdowns and long-term lay-up. This integrated approach follows the ZERUST® Z-CIS® Corrosion Inhibiting System methodology to help extend equipment service life, reduce maintenance costs, and minimize downtime.

For application-specific guidance, equipment owners can contact ZERUST®/EXCOR® to speak with a technical service representative and identify the most effective lay-up rust preventative strategy for their operation.

Get Expert Guidance for Seasonal Shutdown Protection

Work with ZERUST® technical service experts to design a complete system tailored to your equipment, environment, and shutdown duration.