VCI emitters, also called VCI diffusers, protect metal components by releasing vapor corrosion-inhibiting molecules

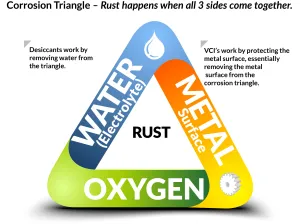

into a sealed or enclosed space. To understand how do VCI emitters work, it’s important to know that these molecules disperse through the air and bond to exposed metal surfaces, where they form an invisible molecular layer that interrupts the electrochemical reactions responsible for rust and corrosion.

Unlike oils, greases, or coatings, VCI emitters do not require direct contact with the metal. Instead, they work through vapor-phase corrosion inhibition, making them especially effective for enclosed environments where traditional rust preventatives are difficult to apply or maintain.

How Do VCI Emitters Protect Metal Surfaces?

Once placed inside an enclosure, VCI emitters continuously release corrosion-inhibiting vapors at a controlled rate. These vapors migrate throughout the space to the metal surfaces. When they settle, they form a temporary protective barrier that blocks moisture, oxygen, and other corrosive elements from interacting with the metal.

Because this protective layer is molecular and self-renewing, it continues to protect metal components as long as the enclosure remains closed and the emitter remains active. When you open the enclosure, the VCI molecules dissipate naturally and leave the metal clean, dry, and ready for immediate use.

Where Are VCI Emitters Most Effective?

VCI emitters provide targeted corrosion protection in hard-to-reach or partially sealed environments where packaging alone may not be sufficient. Common applications include:

- Electrical enclosures and control panels

- Electronics cabinets and junction boxes

- Tool chests, cabinets, and storage lockers

- Shipping containers and crates

- Enclosures with complex geometries or airflow restrictions

In many cases, VCI emitters work alongside VCI films, papers, or bags to provide an extra layer of corrosion protection in demanding environments.

How Long Do VCI Emitters Continue to Work?

The effective lifespan of a VCI emitter depends on the product type, enclosure volume, and environmental conditions. Most emitters are designed to provide continuous corrosion protection for months or even years when used in properly sealed spaces.

Because they release inhibitors gradually and consistently, VCI emitters maintain a protective atmosphere without requiring frequent maintenance or reapplication.

Benefits

VCI emitters offer several advantages over traditional rust prevention methods:

- No oils, greases, or coatings to apply or remove

- No residue left on metal surfaces

- Continuous protection in enclosed spaces

- Effective for complex assemblies and mixed-metal systems

- Reduced labor and maintenance requirements

These benefits make VCI emitters a practical solution for both short-term storage and long-term equipment preservation.

Ready to strengthen corrosion protection?

Learn how VCI emitters can enhance protection in enclosed spaces and complex assemblies.

Can VCI Emitters Be Used With Other Corrosion Protection Products?

Yes. VCI emitters are often used as a complementary solution alongside other corrosion protection methods. For example, they can enhance protection inside packaged assemblies or shipping containers that already use VCI packaging materials.

This layered approach helps ensure consistent corrosion protection in the most extreme environments.

When to Use

VCI emitters are ideal when corrosion protection is needed in enclosed spaces that cannot be fully wrapped, bagged, or coated. They are commonly used for electronics, stored equipment, spare parts, and critical components that must remain clean and immediately operational.

Need help choosing the right solution?

For guidance on selecting the right VCI emitter or determining proper placement, ZERUST® technical support can help ensure optimal corrosion protection for your specific application.