Problem

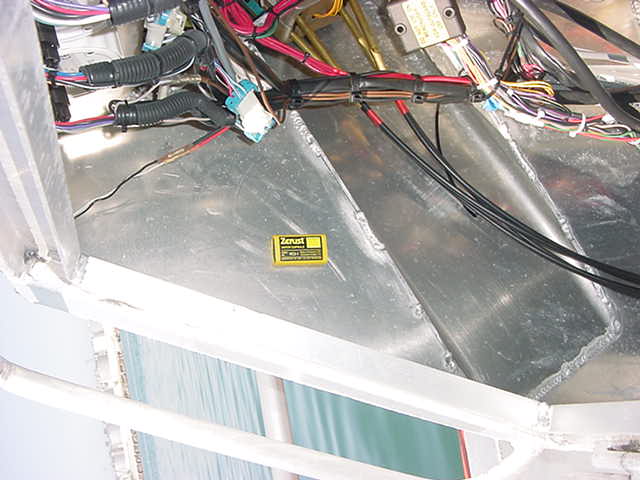

Corrosion damage is especially prevalent in marine environments, where salty air, often combined with high temperatures and humidity levels, makes corrosion prevention challenging. For example, a major naval organization faced serious corrosion issues on ship aids to navigation, bail-out pump motors, and small engines. Corrosion in these areas causes malfunctions and reliability problems that are costly to repair, maintain, or replace and put the people who rely on this equipment at risk. The naval organization’s efforts to combat corrosion included methods such as oiling, scraping, and painting. All of these methods were inefficient, ineffective, and costly.

Marine Equipment Corrosion Solution

They needed a solution that would help mission-critical equipment stay operational and reliable. At the recommendation of ZERUST®, the organization decided to use ZERUST® Vapor Capsules and ZERUST® ICT®510-C Ferrous VCI Bags and Sheeting to protect their aids to navigation, bail-out pump motors, and small engines for a six-month trial period. The tests were extremely successful! No new corrosion was found on any of the equipment. ZERUST® products proved to be an effective solution against corrosion by improving boat operational readiness, equipment reliability and saving critical resources such as time, workforce, and money.