Who?

High-volume contract manufacturer

What?

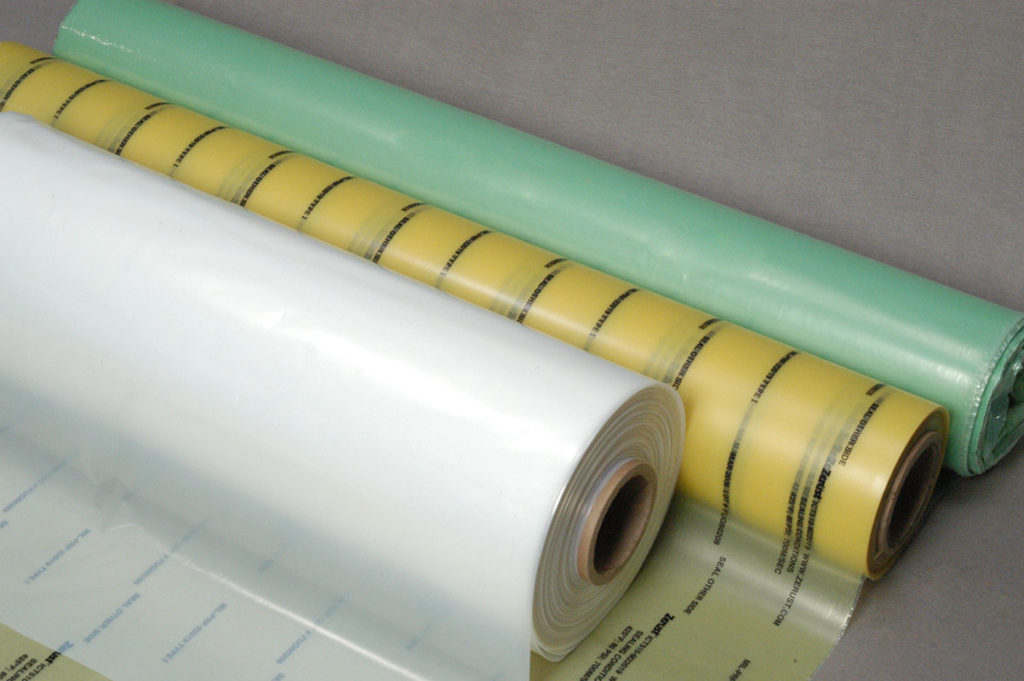

Corrosion prevention for finished parts

Why?

Streamline VCI packaging operations and reduce corrosion

How?

ZERUST® ICT®510-CHLD High-Density VCI Film reduces VCI packaging time and cost and provides superior corrosion protection