Protecting large equipment and metal assets stored outdoors or in extreme environments requires a proven outdoor equipment corrosion protection system. As a result, exposure to rain, UV radiation, temperature swings, salt air, and airborne contaminants can quickly degrade unprotected surfaces. For this reason, ZERUST® addresses these challenges with a system-based approach that combines VCI shrink films, long-term rust preventative coatings, and active moisture control technologies.

Outdoor equipment corrosion protection using VCI shrink film systems

A core component of outdoor equipment corrosion protection is ZERUST® ICT®510-OPS Outdoor Preservation VCI Shrink Film. Therefore, this 8-mil, high-strength shrink film integrates vapor corrosion inhibitor technology with UV stabilizers designed for long-term outdoor exposure.

When heat-shrunk, ICT®510-OPS conforms tightly around large equipment, vehicles, and fabricated structures. The film creates a durable physical barrier that repels rain, snow, dust, and contaminants while saturating the enclosed space with corrosion-inhibiting vapor molecules. These vapors protect exposed metal surfaces as well as internal cavities, seams, and recessed areas that are difficult to coat directly.

To maintain a sealed corrosion-inhibiting environment, installers should seal overlaps, seams, and penetrations using ZERUST® OPS Preservation Tape. Furthermore, proper sealing minimizes air exchange and helps maintain consistent protection throughout extended outdoor storage or lay-up periods.

Long-term outdoor equipment corrosion protection with contact rust preventative coatings

For direct metal surface protection, ZERUST® recommends pairing VCI shrink film with long-term rust preventative coatings as part of a complete outdoor equipment corrosion protection strategy. Products from the Axxanol™ and AxxaCoat™ portfolios provide durable barrier films that protect exposed steel, cast iron, and other ferrous metals.

Axxanol™ Spray-G and the Axxanol™ Z-Maxx Series are sprayable and brushable rust preventative greases designed for long-term outdoor storage. Furthermore, these coatings form robust, water-resistant films that protect flanges, fasteners, welds, shafts, and machined surfaces.

For more demanding outdoor applications, AxxaCoat™ 90B HFS provides a high-flash, corrosion-inhibiting coating engineered to replace traditional hot-melt or heavy wax systems. It delivers strong protection while improving application safety and ease of removal.

Applying these coatings before shrink wrapping ensures that both direct-contact and vapor-phase corrosion protection work together to safeguard critical surfaces.

Enhancing outdoor equipment corrosion protection in extreme and coastal environments

In highly aggressive environments, such as coastal or high-humidity regions, ZERUST® recommends reinforcing outdoor equipment corrosion protection with supplemental vapor and moisture control technologies.

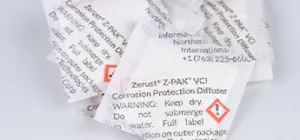

ActivPak® or Z-PAK® VCI emitters increase vapor-phase corrosion protection inside large enclosures, voids, and complex geometries. These emitters continuously release corrosion-inhibiting molecules to maintain protection over extended storage durations.

To control internal humidity, ActivDri™ PWA moisture-control packets actively absorb residual moisture trapped inside the enclosure. Managing humidity reduces the risk of condensation and corrosion caused by temperature fluctuations.

Boost vapor-phase protection in extreme environments

VCI emitters and diffusers enhance corrosion protection by delivering continuous VCI protection inside enclosed and complex geometries.

Surface preparation best practices

Effective outdoor equipment corrosion protection begins with proper surface preparation. Before coating or wrapping, all surfaces should be thoroughly cleaned and dried to remove contaminants that accelerate corrosion.

Use ZERUST® AxxaWash™ industrial cleaners to remove salts, dirt, oils, and residues. After cleaning, allow surfaces to dry completely. Apply the selected Axxanol™ or AxxaCoat™ product according to ZERUST® guidelines and allow coatings to cure as required before wrapping.

Once coated, wrap the asset with ICT®510-OPS shrink film and seal all seams and penetrations to create a tight, weather-resistant enclosure.

Start corrosion protection with proper surface preparation

Industrial cleaners and degreasers remove salts, oils, and contaminants that compromise outdoor equipment corrosion protection before coatings or packaging are applied.

Inspection and maintenance during long-term outdoor storage

Long-term outdoor equipment corrosion protection also depends on periodic inspections. For assets in extended lay-up or mothballing programs, visually inspect the shrink film, seams, and tape for damage. Promptly repair any punctures or compromised areas to maintain the integrity of the corrosion-inhibiting environment.

Complete outdoor equipment corrosion protection with ZERUST®

By combining ICT®510-OPS Outdoor Preservation VCI Shrink Film, Axxanol™ and AxxaCoat™ rust preventative coatings, ActivPak® VCI emitters, ActivDri™ moisture-control packets, and proper surface preparation, ZERUST® delivers a comprehensive outdoor equipment corrosion protection system for large equipment and metal assets exposed to harsh or extreme environments.

This integrated approach reduces corrosion-related rework, preserves asset value, and helps ensure equipment remains ready for service when removed from storage. For help selecting the right solution for your application, contact ZERUST®/EXCOR® to speak with a technical service representative.

Get expert help

ZERUST® technical service experts can help you design a complete corrosion protection system for large equipment and metal assets stored outdoors or in extreme environments.