Choosing the correct VCI packaging depends on the type of metal being protected. Different metals react differently to corrosion inhibitors, so selecting the right formulation is critical for effective protection. This guide explains which VCI packaging you should use for your metal type and how ZERUST® solutions are designed for ferrous, non-ferrous, multimetal, and silver applications.

Which VCI packaging should I use for ferrous metals?

Ferrous metals such as iron, carbon steel, and cast iron are highly susceptible to rust when exposed to moisture and oxygen.

ZERUST®/EXCOR® Ferrous VCI Packaging is specifically formulated to protect these metals by releasing corrosion-inhibiting vapor that forms a protective molecular layer on metal surfaces.

Ferrous VCI packaging is recommended for:

- Carbon steel components

- Cast iron parts

- Machined steel assemblies

- Stamped or fabricated steel parts

Using the correct ferrous formulation ensures long-term protection during storage, shipment, and export.

Choose the right ZERUST® ferrous VCI film

Protect steel, iron, and cast iron parts with ICT®510-C Ferrous VCI Film for reliable corrosion protection during storage and shipment.

Which VCI packaging should I use for non-ferrous metals?

Non-ferrous metals require a different inhibitor chemistry to avoid staining, tarnishing, or surface reactions.

ZERUST®/EXCOR® Non-Ferrous VCI Packaging is designed to protect metals such as aluminum and copper alloys without causing discoloration.

Non-ferrous VCI packaging is ideal for:

- Aluminum and aluminum alloys containing copper or manganese

- Copper components

- Brass and bronze parts

- Fully galvanized steel

When deciding which VCI packaging to use for my metal, non-ferrous formulations, appearance-critical and precision components require essential VCI packaging.

Choose the right ZERUST® non-ferrous VCI film

Protect aluminum, copper, brass, bronze, and galvanized steel with ICT®510-C Non-Ferrous VCI Film without staining or discoloration.

Which VCI packaging should I use for multimetal assemblies?

Many modern products contain both ferrous and non-ferrous metals in a single assembly. These combinations increase the risk of galvanic corrosion if not properly protected.

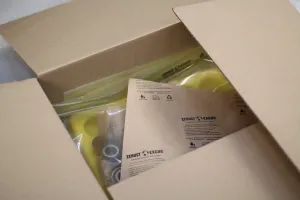

ZERUST®/EXCOR® Multimetal VCI Packaging provides balanced corrosion protection for multimetal parts using a formulation compatible with both metal types.

Multimetal VCI packaging is recommended for:

- Assemblies containing steel and aluminum

- Components with copper and steel interfaces

- Complex fabricated parts with mulitple materials

- Electrical and mechanical assemblies

If your product contains more than one metal, multimetal packaging is often the safest answer to which VCI packaging should I use for my metal.

Choose the right ZERUST® multimetal VCI film

Protect multimetal assemblies with ZERUST® ICT®510-C Multimetal VCI Film for balanced corrosion protection across ferrous and non-ferrous surfaces.

Which VCI packaging should I use for silver and precious metals?

Silver and silver-plated components are vulnerable to tarnishing caused by sulfur compounds and acidic gases rather than traditional rust.

ZERUST®/EXCOR® Anti-Tarnish VCI Packaging protects silver by combining corrosion inhibitors with acid-gas scavenger additives that neutralize tarnish-causing contaminants.

Anti-tarnish VCI packaging is commonly used for:

- Silver electrical contacts

- Silver-plated connectors

- Precision instruments

- Decorative or appearance-critical components

Selecting the correct anti-tarnish solution ensures silver parts remain clean and functional.

CTA FOR https://www.zerust.com/products/vci-packaging-films/zerust-ict520-cb1-anti-tarnish-film/

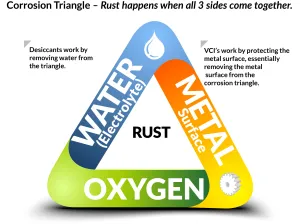

Why metal type matters when deciding which VCI packaging to use

VCI chemistry must match the metal surface to be effective. Using the wrong formulation can result in:

- Reduced corrosion protection

- Surface staining or discoloration

- Tarnishing of sensitive metals

- Shortened protection life

That is why identifying the metal type is the first step in determining which VCI packaging should I use for my metal.

How to identify which VCI packaging to use

Before selecting VCI packaging, confirm:

- The base metal or metals in the part

- Whether alloys contain copper or manganese

- If multiple metals are in contact

- Appearance or cleanliness requirements

When metal composition is uncertain, ZERUST® corrosion experts can help evaluate the application and recommend the correct solution.

Summary: Which VCI packaging should I use for my metal?

- Ferrous metals use ZERUST®/EXCOR® Ferrous VCI Packaging

- Non-ferrous metals use ZERUST®/EXCOR® Non-Ferrous VCI Packaging

- Multimetals use ZERUST®/EXCOR® Multimetal VCI Packaging

- Silver uses ZERUST®/EXCOR® Anti-Tarnish VCI Packaging

Selecting the correct packaging ensures reliable corrosion protection and prevents costly damage during storage and shipment.

Need help choosing the right VCI packaging?

ZERUST® corrosion experts can help you select the correct product for your application, environment, and protection duration.