Page 5 of 7

What Should You Consider When Choosing a VCI Supplier?

Are you in search of a VCI supplier due to company specifications? Currently experiencing corrosion issues at your facility? or just unhappy with the products and services provided by your current VCI supplier? No matter the reason for your search, when choosing a VCI supplier, you should consider this. Is the VCI supplier reputable (ISO

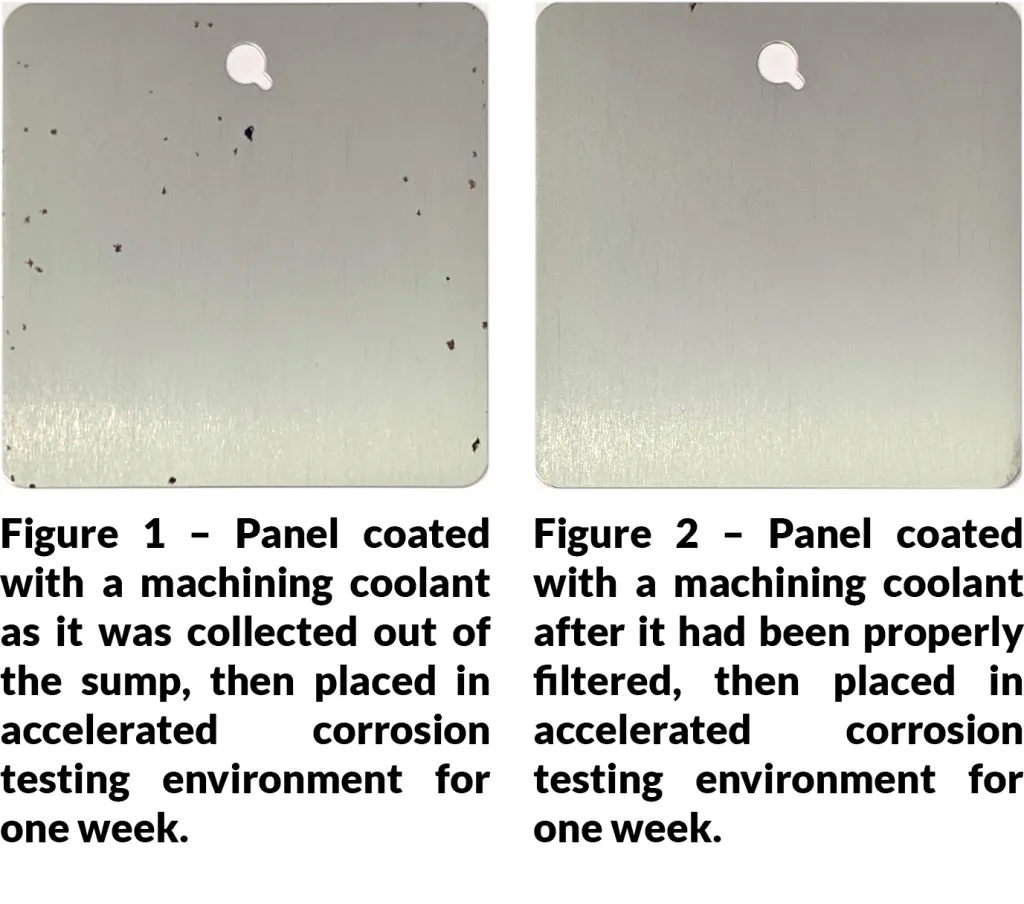

Metalworking Fluids Maintenance: Proper Filtration

Washes, rinses, machining coolants, lubricants, rust preventatives, and other metalworking fluids (MWFs) are frequently used in industrial manufacturing facilities. Proper maintenance of metalworking fluids is required to preserve the fluid’s health, increase the fluid’s lifetime, minimize corrosion risk, and even reduce wear and tear on tools and machines. Unfortunately, proper filtration is one of the

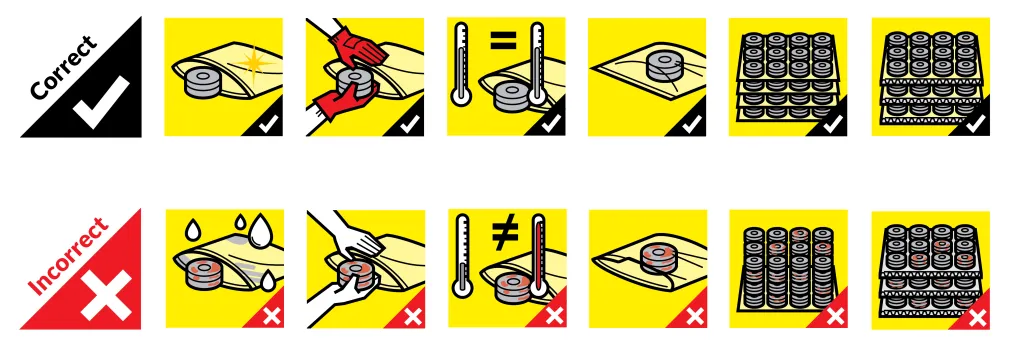

How to use ZERUST® VCI Products Correctly

For nearly 5 decades now, manufacturers and OEMs across the globe have been incorporating ZERUST® Vapor Corrosion Inhibitor (VCI) products into their packaging applications to prevent rust and corrosion during shipping and storage of their metal goods. However, despite years of experience, not everyone fully understands how VCI works and how to use it correctly

AxxaVis™ HST-10 – An Environmentally Friendly and Effective Hydrostatic Testing Additive

Industry professionals widely perform hydrostatic testing as a standard method to verify the structural integrity and leak-tightness of pressure vessels. These include pipelines, plumbing systems, gas cylinders, boilers, above-ground storage tanks (ASTs), and fuel tanks. Testing these vessels is critical, especially when they are intended to transport or store gases. This is because failure under

The Various Official Flavors of the Jar Test: Evaluating the Efficacy of Volatile Corrosion Inhibitors (VCI)

The use of anti-corrosive packaging materials functionalized with volatile corrosion inhibitors (VCI) to preserve processed metal parts is critical for any good corrosion management program. Evaluating the efficacy of VCI packaging to provide off-contact protection of steel surfaces is commonly performed in the laboratory using the Vapor-phase Inhibition Ability (VIA) test, also known as the

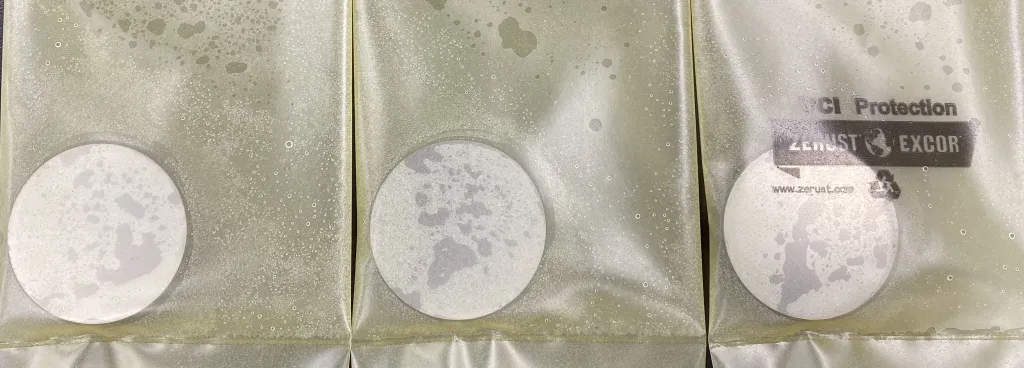

When VCI Jar Testing Is Not Enough

While the NACE Standard TM0208 Vapor Inhibition Ability (VIA) test, also known as the VCI jar test, is a powerful tool for rapid analysis of VCI packaging and chemistry, it isn’t always robust enough to evaluate the complete protection of VCI packaging. In addition, it is even more limited in its capabilities for testing things

Corrosion Considerations Regarding the Concentration Effect in Metalworking Fluids

What is the concentration effect? We have all seen the concentration effect occur in our daily lives. With a kitchen sink full of soapy water used to wash dishes, the more dishes you wash in the water, the dirtier the water gets, and the less effective it becomes at cleaning dishes. As the water in

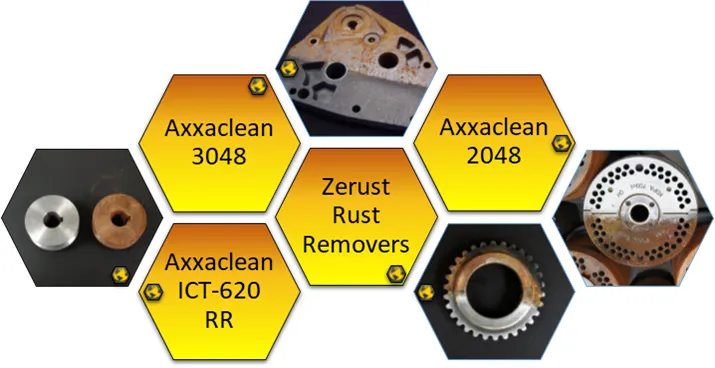

What Is the Best Rust Remover?

Globally, rust is a significant problem. The United States Navy alone calls it a $6 billion problem. The National Association of Corrosion Engineers (NACE) put the cost at 276 billion dollars annually. It affects governments, businesses, and consumers alike. The best approach is to stop rust before it starts using one or multiple approaches such

The Cost of Corrosion

Rust can be an ugly sight. But when it comes to the industries that rely on non-corroded metal to run, rust can also lead to some nasty consequences that aren’t always quite so visible: lack of productivity, accidents, and a significant financial loss. Companies are leaching billions of dollars out of their business each year