What to Do When Rust Prevention Fails?

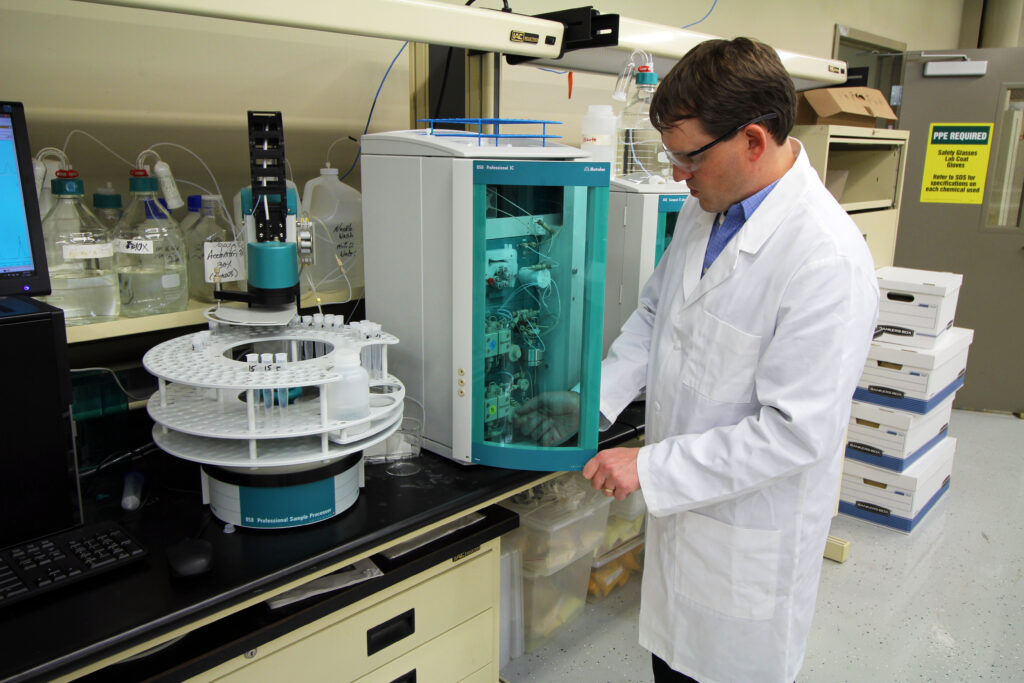

In the manufacturing world, many companies go to great lengths to select products and processes to prevent rust and corrosion from forming on their valuable metal assets during transit and storage. They will probably incorporate volatile corrosion inhibitor (VCI) packaging, rust preventative (RP) coatings, desiccants, or some combination of them. But what happens when their

Using Electrochemical Impedance Spectroscopy (EIS) Method for a Better Understanding of the Corrosion System

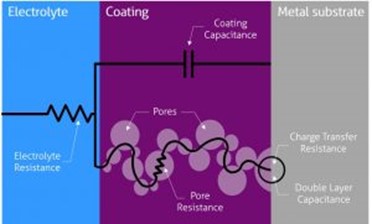

The corrosion rate is controlled by different factors such as pH, temperature, electrochemical potential, electrolyte, and as well as the applied corrosion control method. Those factors together make the corrosion control method evaluation complex and time-consuming. As we all know, corrosion is an electrochemical procedure. The concept of electrical resistance tells us the higher the