Corrosion is a silent threat that plagues control rooms and electronics in industrial settings. As a result, it can cause circuitry failures, compromise equipment reliability, and ultimately lead to costly downtime. In this blog post, we’ll explore the challenges of corrosion control in control rooms and electronics and how innovative products like ZERUST® ActivDri™ Packets, Vapor Capsules, and Axxanol™ 718-ESS electrical corrosion inhibitor spray can be valuable allies in the battle against corrosion.

Corrosion is a silent threat that plagues control rooms and electronics in industrial settings. As a result, it can cause circuitry failures, compromise equipment reliability, and ultimately lead to costly downtime. In this blog post, we’ll explore the challenges of corrosion control in control rooms and electronics and how innovative products like ZERUST® ActivDri™ Packets, Vapor Capsules, and Axxanol™ 718-ESS electrical corrosion inhibitor spray can be valuable allies in the battle against corrosion.

The Corrosion Challenge

Corrosion of electronics due to ambient air pollution has been a long-standing issue, especially in heavy industrial environments such as paper mills, petrochemical refineries, and wastewater treatment plants. These facilities often produce sulfur-containing gases like hydrogen sulfide, sulfur dioxide, and mercaptans, which are corrosive to electronic components.

The European Union’s Restriction of Hazardous Substances (RoHS) Directive, enacted in 2003, has further exacerbated the corrosion problem. RoHS compliance led to changes in materials used in electronic equipment, making them more susceptible to gaseous corrosion. As a result, circuitry failures can occur rapidly, even in environments previously considered safe.

Types of Electronic Corrosion

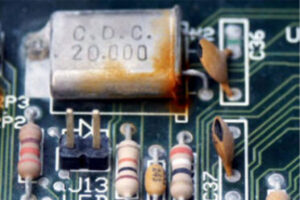

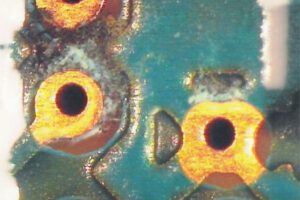

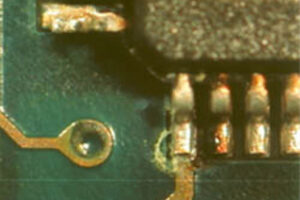

There are several forms of electronic corrosion, including whisker growth and creep corrosion. These corrosion types can impede the flow of electricity or create unintended circuit paths, ultimately leading to equipment failure.

|

|

|

For example, silver whisker growth on circuit boards is a clear indicator of sulfur contamination. It forms unintended circuit paths and serves as a warning sign for manufacturers.

Environmental Conditions for Control Rooms and Electronics

As electronics become smaller and denser, they generate more heat and require increased airflow to prevent overheating. This presents challenges in sealing and protecting electronic components from environmental conditions, including molecular contamination.

To address these issues, a standard was developed to classify control rooms and process control environments. Meeting the ISA G1 – Mild classification is often necessary for maintaining reliable communication networks in industrial settings. Achieving this classification often requires the use of chemical and particulate filtration.

Most electronics manufacturers require environments with a copper corrosion rate below 300 Angstroms per month and a silver corrosion rate below 200 Angstroms per month to ensure equipment reliability and uphold warranties.

Particulate Contamination and Control

Corrosion-related failures can also occur due to dust, which falls into three categories:

- Mechanical effects: Dust can obstruct cooling airflow, interfere with moving parts, and deform surfaces.

- Chemical effects: Dust containing sulfur and chlorine-bearing salts can corrode electrical components.

- Electrical effects: Fine dust particles can lead to impedance changes and circuit conductor bridging.

Dust particles, especially when moistened, contribute to corrosion and ion migration, accelerating equipment failures. Proper air filtration is essential, with MERV 8 filtration for recirculated air within computer rooms and MERV 11 or MERV 13 filtration for outside air.

Corrosion Control Products by ZERUST®

To combat corrosion effectively, ZERUST® offers a range of innovative products designed to protect control rooms and electronics.

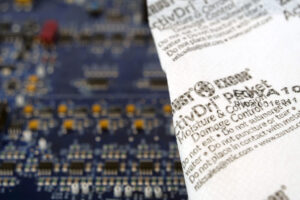

ZERUST® ActivDri™ Packets

ZERUST® ActivDri™ Packets are patent-pending moisture control vapor corrosion inhibitor (VCI) sachet products. These sachets protect against environmental contaminants and humidity, which aggressively corrode metal parts and electronic components. Corrosion of these components can lead to quality rejections, system reliability issues, malfunctions, and production stoppages.

The dual-action of ActivDri™ packets provides both moisture control and corrosion prevention. They are easy to use and offer effective protection during operation, shipping, and storage of metal parts and electrical components.

ZERUST® Axxanol™ 718-ESS Electrical Corrosion Inhibitor Spray

ZERUST® Axxanol™ 718-ESS is a versatile electrical corrosion inhibitor spray designed for challenging environments with acid gas vapors and humidity. This spray creates a thin, non-staining, non-hardening, soft film on metal surfaces, providing corrosion protection and lubrication.

Axxanol™ 718-ESS is suitable for various metal applications, including hinges, machinery, electronic components, electric cabinets, and junction boxes. It ensures that the conductivity of electronic components remains unaltered and adheres to key aspects of MIL-PRF-81309H standards. It is safe for use, free from CFCs, or 1,1,1-Trichloroethane.

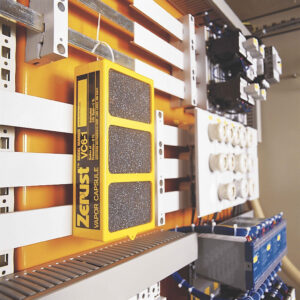

ZERUST® Vapor Capsules

ZERUST®/EXCOR® Vapor Capsules are portable capsules containing patented ZERUST® VCI technology. These capsules emit Vapor Corrosion Inhibitor Technology (VCI), preventing oxidation and rust formation on metal surfaces. Vapor Capsules are particularly useful for protecting metals in hard-to-reach areas within control panels, electrical cabinets, and other enclosed spaces.

Installing Vapor Capsules is a simple process. Just peel back the protective paper from the adhesive tape and secure the capsule in the desired location. When the enclosure is tightly sealed, metals remain protected from rust and tarnish for up to one or two years, depending on the capsule model and environment.

Benefits of ZERUST® Corrosion Control Products

- Reliable Protection: ZERUST® products are designed to offer reliable protection against corrosion, ensuring the longevity and reliability of electronic components and metal parts.

- Easy to Use: ZERUST® products are user-friendly, making them accessible to various industries and applications.

- Safety: These products are safe for use and conform to industry standards, assuring the safety of both equipment and personnel.

- Customization: ZERUST® offers customization options for specialized applications, allowing businesses to tailor corrosion control solutions to their specific needs.

Effective corrosion control is vital in control rooms and electronics to ensure equipment reliability and minimize downtime. ZERUST®’s range of innovative products, including ActivDri™ Packets, Axxanol™ 718-ESS Electrical Corrosion Inhibitor Spray, and Vapor Capsules, provide powerful tools to combat the corrosive effects of industrial environments. By incorporating these solutions into your maintenance and protection strategies, you can safeguard your electronics and metal components, reduce maintenance costs, and extend the operational life of critical equipment.