How is corrosion prevented is a common question for manufacturers, shippers, and maintenance teams looking to protect metal assets throughout storage, transportation, and work-in-progress. Furthermore, corrosion prevention focuses on interrupting the conditions that allow metal to deteriorate. As a result, most strategies do this by limiting moisture, oxygen, or corrosive contaminants from reaching the metal surface.

At its core, corrosion prevention works by creating a protective barrier between metal and its environment. Consequently, this barrier slows or stops the electrochemical reactions that cause rust and other forms of corrosion.

Common Methods Used to Prevent Corrosion

Several proven approaches prevent corrosion, depending on the application, environment, and required duration of protection.

Environmental control

One way to prevent corrosion is to modify the surrounding atmosphere. Techniques such as dehumidification, nitrogen purging, or evacuation reduce the amount of moisture and oxygen available to react with metal. These methods work well in enclosed spaces but often require continuous monitoring and energy input.

Surface barriers and coatings

Another approach is applying a physical barrier directly to the metal surface. Oils, greases, waxes, or protective coatings block moisture from contacting the metal. While effective, these methods may require additional labor to apply and remove, and can leave residues that interfere with downstream processes.

Vapor Corrosion Inhibitor protection

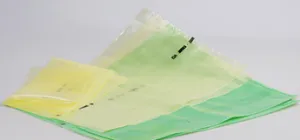

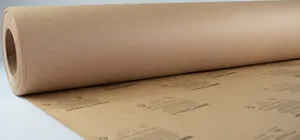

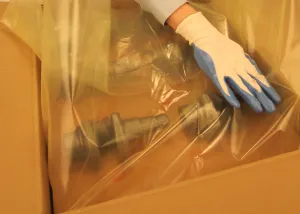

A more efficient way to prevent corrosion is to use Vapor Corrosion Inhibitor Technology (VCI). VCI products release corrosion-inhibiting molecules into a sealed environment. These molecules travel through the air and bond to metal surfaces, forming an invisible protective layer that shields the metal from moisture, oxygen, and corrosive contaminants.

How Corrosion is Prevented using Vapor Corrosion Inhibitors

Vapor Corrosion Inhibitors prevent corrosion by diffusing protective molecules from a source such as VCI film or paper to exposed metal surfaces. Once the enclosure is sealed, these molecules disperse evenly throughout the airspace and settle on the metal.

This molecular layer disrupts the electrochemical reactions responsible for corrosion formation. As a result, metal remains protected even in challenging environments such as high humidity, long-term storage, or overseas shipment. When the packaging is opened, the molecules naturally dissipate, leaving the metal surface clean and residue-free.

ZERUST® Corrosion Prevention Solutions

ZERUST® combines vapor corrosion inhibitor technology with material science expertise and process management to deliver comprehensive corrosion prevention solutions. This integrated approach is known as ZERUST®/EXCOR® Integrated Corrosion Technologies (ICT®).

Rather than offering a one-size-fits-all product, ZERUST® evaluates the full supply chain, including manufacturing processes, packaging, logistics, storage conditions, and end use. This allows corrosion prevention strategies to be tailored to specific metals, environments, and durations.

With global technical support in over 70 countries, ZERUST® helps organizations reduce corrosion-related damage, rework, and costs across industries.

Ready to Strengthen Your Corrosion Prevention Strategy?

Instead of relying on generic solutions, work directly with ZERUST® specialists to design a corrosion prevention program tailored to your metals, environments, and supply chain.

Choosing the Right Approach to Prevent Corrosion

How corrosion is prevented depends on factors such as exposure time, humidity, transportation distance, and metal type. For short-term protection, surface coatings may be sufficient. For long-term storage, export shipping, or corrosive environments, combining VCI packaging with environmental controls often delivers the most reliable results.

If you face a challenging corrosion prevention requirement, such as overseas shipping or long-term storage in harsh conditions, working with corrosion specialists can help ensure your metals remain protected throughout their lifecycle.

Need Help Choosing the Right Corrosion Prevention Method?

When conditions become more demanding, ZERUST® can help you select the right combination of VCI packaging, environmental controls, and process improvements to protect metal throughout its lifecycle.