FProtecting metal parts in high-humidity and coastal environments requires a coordinated, system-based approach. Moisture, salt, and airborne contaminants significantly accelerate corrosion, especially in coastal plants and marine-adjacent facilities. Furthermore, to protect metal parts in high-humidity and coastal environments, ZERUST® recommends combining surface preparation, environmental control, and VCI technology as part of its proven Z-CIS® Corrosion Inhibiting System methodology.

This layered strategy reduces corrosion risk by addressing both direct surface exposure and hidden or hard-to-reach areas that are vulnerable to moisture and salt intrusion.

Surface preparation is the foundation to protect metal parts in high-humidity and coastal environments

Before storage, parts must be clean and free of salts, fingerprints, machining residues, and coolant films. As a result, these contaminants attract moisture and accelerate corrosion in humid and coastal conditions.

ZERUST® AxxaWash™ industrial cleaners remove corrosive residues without leaving behind harmful films. In coastal plants where salt fog or airborne chlorides are present, periodic cleaning helps prevent salt buildup on exposed surfaces. After cleaning, parts should be thoroughly dried before protective measures are applied to reduce the risk of flash rust.

Apply rust preventative coatings to protect metal parts in high-humidity and coastal environments

After cleaning, apply a ZERUST® Axxanol™ rust preventative coating selected based on storage duration and environmental severity. These coatings create a physical barrier that blocks moisture and corrosive contaminants.

Light- to medium-duty oils such as Axxanol™ 33, 750-NV, 758-NV, 46-BIO, A35-30, or A35-8030 provide reliable humidity resistance for indoor storage. For prolonged exposure, outdoor layup, or severe coastal environments, heavy-duty coatings such as Axxanol™ Spray-G or Axxanol™ Z-Maxx deliver extended protection and superior moisture resistance.

Apply rust preventative coatings to protect metal parts

Explore ZERUST® rust inhibitor coatings engineered to deliver reliable protection in humid, coastal, and corrosion-prone storage and operating environments.

Use VCI packaging to protect metal parts in high-humidity and coastal environments

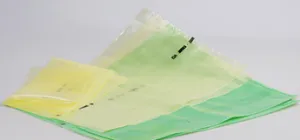

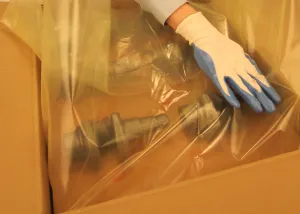

VCI packaging protects areas that coatings may not fully reach, including internal cavities, recessed features, and uncoated surfaces. ZERUST® ICT® VCI films, bags, and shrink films release corrosion-inhibiting molecules that form a protective molecular layer on exposed metal surfaces inside a sealed enclosure.

For stacked or nested components, interleave parts with ZERUST® ICT® VCI Paper to ensure consistent vapor coverage. Additionally, in outdoor or extreme coastal conditions, ZERUST® ICT®510-OPS Outdoor Preservation VCI Film provides enhanced durability and weather resistance.

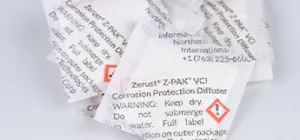

Adding ZERUST® ActivDri™ PWA Moisture-Control Packets inside sealed packaging helps stabilize the microenvironment by absorbing excess humidity while simultaneously releasing VCI protection. For crates, totes, and large enclosures, ZERUST® VCI emitters such as Vapor Capsules, ActivPak®, or Z-PAK® distribute corrosion protection throughout the enclosed space.

Environmental controls help protect metal parts in high-humidity and coastal environments

Environmental management plays a critical role in corrosion prevention. Whenever possible, maintain storage areas below 50 percent relative humidity and ensure steady airflow to minimize condensation cycles.

Avoid placing metal parts directly on wood pallets or shelving. Wood can emit organic acids and retain moisture, increasing corrosion risk. Use ZERUST® VCI film or paper as a barrier layer between metal and wood surfaces. In coastal plants with salt fog exposure, periodic rinsing with AxxaWash™ cleaners followed by reapplication of protective coatings helps remove accumulated salt deposits.

Inspection and maintenance are essential

Corrosion protection is not a one-time activity. Stored parts should be inspected every three to six months for signs of condensation, packaging damage, or coating degradation. Furthermore, replace VCI packaging and moisture-control products as needed, and reapply coatings to maintain continuous protection.

By combining AxxaWash™ cleaning, Axxanol™ rust preventative coatings, ICT® VCI packaging, ActivDri™ moisture control, and proper environmental management, ZERUST® delivers a robust and scalable solution to protect metal parts in high-humidity and coastal environments. Additionally, for application-specific guidance, contact ZERUST® to speak with a technical service representative.

Need help protecting metal parts in high-humidity and coastal environments?

ZERUST® corrosion experts can help you select the right combination of cleaners,

rust preventative coatings, VCI packaging, and moisture control for your

specific storage or operating conditions.