VCI bags, or vapor corrosion inhibitor bags, protect metal parts from rust and corrosion by releasing vapor corrosion inhibitor molecules into a sealed environment. If you’re wondering how do VCI bags work, these molecules disperse throughout the enclosed air space, and once they reach the metal, they form an invisible, molecular-level protective layer that interrupts the electrochemical reactions responsible for corrosion.

Unlike oils, greases, or coatings, VCI bags protect metals without direct contact or affecting the metal surface. When the bag is opened, the protective molecules dissipate, leaving metal parts clean, dry, and ready for immediate use.

How VCI Bags Prevent Rust and Corrosion

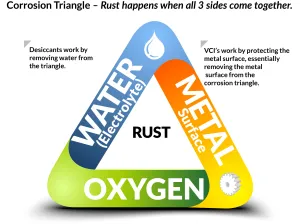

To understand how VCI bags work, it helps to look at what causes corrosion. Rust and other forms of corrosion require three elements: metal, oxygen, and moisture or other contaminants. VCI bags work by disrupting this process.

To understand how VCI bags work, it helps to look at what causes corrosion. Rust and other forms of corrosion require three elements: metal, oxygen, and moisture or other contaminants. VCI bags work by disrupting this process.

Inside a sealed VCI bag, corrosion inhibitor vapors bond to the metal surface and create a temporary molecular barrier. This barrier blocks moisture, oxygen, and airborne contaminants from initiating the electrochemical corrosion cycle. Moreover, as long as the enclosure remains sealed, the protective environment stays active.

What Happens Inside a Sealed VCI Bag?

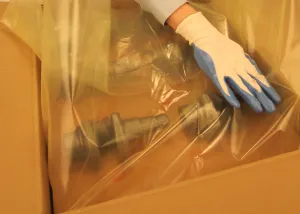

Once metal parts are placed inside a VCI bag and the bag is properly sealed, the corrosion-inhibiting molecules activate. These molecules distribute evenly throughout the package. Furthermore, the vapor fills void spaces, reaches recessed areas, and protects complex geometries. Traditional coatings often miss these areas.

Because the protection occurs in the vapor phase, VCI bags can safeguard internal surfaces, threads, cavities, and assembled components. There is no need to clean or perform additional labor after parts are removed from the packaging.

Metal Protection Types

VCI bags can protect a wide range of metals, including ferrous and non-ferrous materials. Depending on the formulation, they are commonly used to protect carbon steel, cast iron, stainless steel, aluminum, copper, brass, and multimetal assemblies.

Multimetal VCI bags are especially useful for assemblies that combine different alloys, helping reduce the risk of corrosion during storage or shipment.

|

Now choose the right protection.

|

|

When Should You Use VCI Bags?

VCI bags are ideal for corrosion protection during storage, transportation, and export packaging. Manufacturers often use them to protect metal parts between production steps, during long-term warehousing, or when shipping components through humid or corrosive environments.

They are also widely used for spare parts, maintenance kits, and tooling where clean, residue-free protection is required at the point of use.

Best Practices

To get the most protection from VCI bags, always select the correct bag size and type for your application and seal the bag tightly. Parts should be visibly dry and free of standing water before packaging. Minimizing unnecessary openings helps maintain vapor concentration and long-term corrosion protection.

In more demanding environments, VCI bags can be combined with desiccants or other Vapor Corrosion Inhibitor products to enhance performance.

Want to apply these best practices correctly?

Then review our step-by-step guide to using ZERUST® VCI products for maximum corrosion protection.

Why Choose VCI Bags Instead of Traditional Rust Preventatives?

Traditional rust preventatives, such as oils or coatings, require additional application, removal, and disposal steps. VCI bags simplify corrosion protection by eliminating these extra processes. They reduce labor, minimize waste, and help improve overall efficiency while still providing reliable protection against rust and corrosion.

ZERUST® manufactures VCI bags to support clean manufacturing, streamlined logistics, and consistent corrosion control across global supply chains.

|

Need expert guidance for your application? |

Contact ZERUST® |

Based on the metals you need to protect, select the appropriate ZERUST® VCI film.

Based on the metals you need to protect, select the appropriate ZERUST® VCI film.