Yes. Our internationally recognized scientists and corrosion engineers work closely with customers to design and implement comprehensive corrosion management systems. As part of the process, customer parts along with proposed rust preventative solutions can be subjected to accelerated corrosion testing in the various climate stress simulation chambers available at our technical support laboratories that are strategically located in major industrialized regions around the world.

What Is Accelerated Corrosion Testing?

Accelerated corrosion testing uses specialized environmental chambers to simulate harsh conditions over a shorter timeframe, enabling engineers to assess how metals, coatings, rust preventatives, packaging, and corrosion solutions perform under stress. These tests accelerate the appearance of corrosion and provide data that helps engineers validate protection strategies before actual field exposure or long-term storage.

ZERUST’s global technical support labs are designed to address complex corrosion challenges through controlled, repeatable testing methods, including salt spray, humidity, cyclic temperature/humidity cycles, and other climate simulations.

Available Corrosion Test Methods and Simulations

ZERUST®/EXCOR® can tailor laboratory corrosion testing to your needs. Common tests include:

Salt Spray (Fog) Testing

Salt Spray (Fog) Testing

A widely used accelerated corrosion method that exposes components or coatings to a fine mist of salt-laden air, helping predict how protective systems resist corrosion in marine or high-salt environments. Results often indicate the time to first corrosion appearance under aggressive conditions.

Humidity Chamber Testing

Humidity Chamber Testing

This test exposes materials to controlled, high-humidity conditions to simulate tropical or moisture-rich environments and evaluate how well rust preventatives or packaging protect against condensation-related corrosion.

Cyclic Temperature and Humidity Testing

Cyclic Temperature and Humidity Testing

This method alternates between hot, humid conditions and cooler conditions to simulate real-world thermal cycling, which can stress materials and coatings. Alternating conditions reveal performance differences that a single constant environment may not show.

Gas Corrosion Testing (e.g., Hydrogen Sulfide, Sulfur Dioxide)

Gas Corrosion Testing (e.g., Hydrogen Sulfide, Sulfur Dioxide)

Chambers can test the effects of corrosive gases that metals may encounter in industrial or polluted environments, providing accelerated insight into corrosion risk and corrosion resistance.

Benefits of Accelerated Corrosion Evaluation

Accelerated corrosion testing helps manufacturers and corrosion engineers:

- Validate protective coatings and rust inhibitors before large-scale deployment

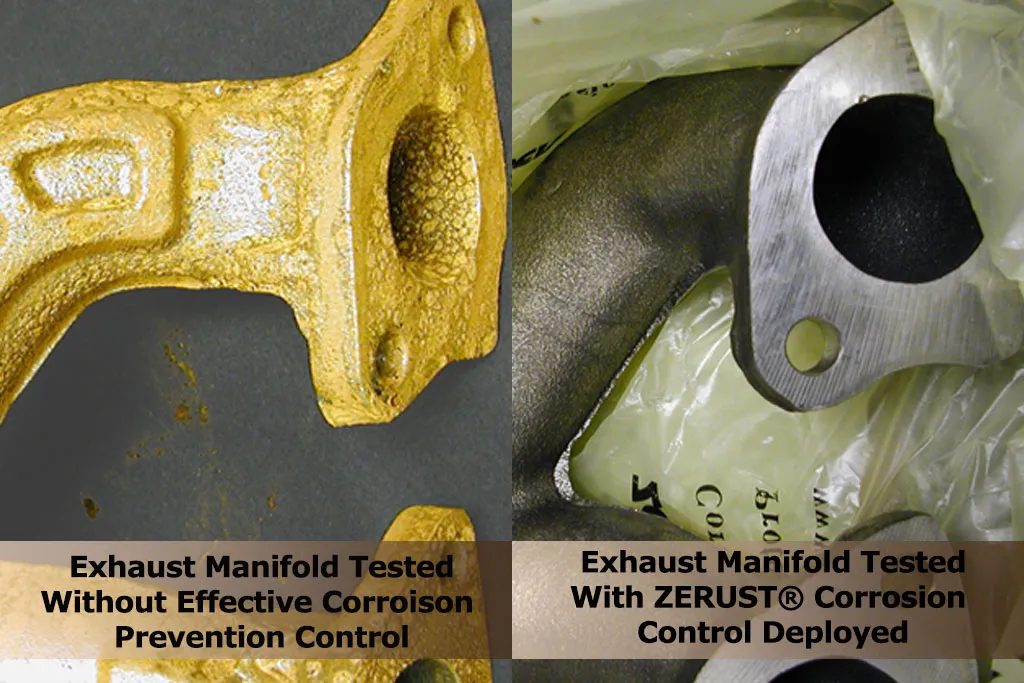

- Compare different corrosion solutions under identical stress conditions

- Estimate relative corrosion rates for components, coatings, fluids, or packaging materials

- Support design decisions with quantitative test data

- Reduce risk by identifying weaknesses before shipping, storage, or field service

These tests can inform decisions on materials, coatings, packaging design, and corrosion-control strategies well before real-world corrosion occurs.

Need Accelerated Corrosion Testing for Your Application?

ZERUST® corrosion engineers work with customers to design corrosion testing programs that validate coatings, packaging, fluids, and corrosion protection systems under simulated environmental conditions.

Laboratory Capabilities and Technical Approach

ZERUST®/EXCOR® operates multiple laboratories and test facilities worldwide as part of its global support network for technical services. Additionally, these facilities are equipped with advanced corrosion test chambers that simulate a wide range of environmental conditions. Scientists and corrosion engineers work directly with customers to:

- Define testing objectives

- Select appropriate test protocols (e.g., ASTM, IEC standards)

- Prepare and condition test specimens

- Execute accelerated chamber testing

- Analyze results and interpret corrosion performance

- Report findings in a clear technical format

In many cases, ZERUST® labs also support VCI standard tests, humidity evaluations, mechanical analysis, and chemical characterization as part of a holistic corrosion management approach.

Common Applications and Use Cases

Accelerated corrosion testing is especially valuable when:

- A new product design requires corrosion performance verification

- You’re selecting between multiple rust preventatives or coatings

- Packaging systems (including VCI solutions) must be validated for export or long-term storage

- Environmental exposure conditions are severe or unknown

- Regulatory or quality standards demand performance documentation

Working with ZERUST® early in the design or process development phase often yields the most actionable insights.

What Happens After Testing?

What Happens After Testing?

Once accelerated corrosion testing is completed, you will typically receive:

- A detailed test report summarizing conditions and outcomes

- Photographs and visual documentation of corrosion results, if applicable

- Comparative performance data across test specimens

- Recommendations for corrosion protection solutions based on observed behavior

The data generated helps guide corrosion mitigation strategies with confidence.

Explore Accelerated Corrosion Testing for Your Application

From salt spray and humidity testing to cyclic climate simulations, ZERUST® laboratories

help customers validate corrosion protection strategies before products ship or enter

long-term storage.

Request Technical Support or Lab Services

If you’re considering accelerated corrosion testing for parts, coatings, packaging materials, or corrosion solutions, ZERUST®’s corrosion specialists can help design the appropriate protocol and interpret the results.

Reach out to your local ZERUST® representative or technical support team to discuss your testing requirements.