We are commonly asked, does VCI work on wet parts? This question often comes up after machining, washing, or rinsing operations where parts still have light moisture or water-based coolant residue on the surface. ZERUST® VCI technology can protect metal parts in these situations when moisture levels are controlled and corrosive residues are removed. However, VCI does not displace standing water, so parts should be clean and surface dry before being sealed in VCI packaging to ensure reliable corrosion protection.

VCI technology works by releasing corrosion-inhibiting vapor inside the sealed enclosure. These vapor molecules migrate to exposed metal surfaces and form a protective barrier. When excess liquid remains on the part, the vapor cannot fully interact with the metal, which may limit protection.

How coolant chemistry affects whether VCI works on wet parts

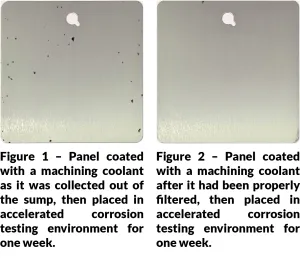

Whether VCI works on wet parts depends heavily on the chemistry of the coolant or machining fluid. Some water-based coolants are compatible with VCI protection, while others contain salts, chlorides, or additives that promote corrosion.

If corrosive residues remain on the part, moisture trapped inside the package can accelerate rust. Evaluating coolant formulation and cleanliness is essential before relying on VCI protection.

Best practices to ensure VCI works on wet parts

To improve performance when packaging wet or freshly machined components, follow these best practices:

- Drain or rinse off excess coolant

- Remove corrosive residues using appropriate cleaners

- Allow parts to reach a visibly surface-dry condition

- Avoid sealing standing water inside the package

Following these steps helps ensure VCI works by allowing vapor to distribute evenly throughout the enclosure.

Need help ensuring VCI works on wet parts?

ZERUST® corrosion experts can evaluate your process, coolant chemistry, and packaging conditions to help ensure your parts remain corrosion free during storage and shipment.

Does VCI work on wet parts to prevent flash rust?

VCI helps prevent corrosion once parts are surface dry and enclosed. However, it does not stop flash rust if active moisture and corrosive residues remain on the metal.

For applications with high humidity or freshly washed parts, ZERUST® recommends combining VCI packaging with rust preventative liquids or moisture control products to enhance protection.

When additional protection is needed for wet parts

In demanding environments, relying on VCI alone may not be sufficient. ZERUST® offers complementary solutions to ensure corrosion protection when wet parts are involved, including water-based rust inhibitors, oil-based protectants, and VCI emitters for enclosed spaces.

Using a layered approach improves consistency and long-term performance.

Talk to a ZERUST® Corrosion Expert

Not sure if VCI is right for your wet parts, coolant conditions, or storage environment? ZERUST® specialists can help you select the right corrosion protection solution for your process.

ICT®510-C VCI Film provides cost-effective and versatile protection against rust and corrosion damage for metal assets in shipping and storage. Additionally, it’s available in ferrous, non-ferrous, and multimetal formulations, as well as various-sized rolls, sheets, tubing, and bags.

ICT®420 is an acid-free, pH-neutral, and non-abrasive VCI kraft paper that merges the practicality and cost-efficiency of paper-based packaging with advanced corrosion protection. Consequently, it streamlines the preservation of metals during work-in-progress, shipping, and storage.

ActivPak® is a versatile and powerful fast-acting VCI sachet designed to address flash rust and corrosion concerns in demanding scenarios, including overseas shipping and polluted factory environments.

ActivPak®(LS) Flash Corrosion VCI Emitters offer fast-acting corrosion protection in challenging conditions, such as factories, marine environments, waste treatment facilities, and power plants.

ActivDri™ PWA Packets are patent-pending, economical, effective, and easy-to-use dual-action, moisture control Vapor Corrosion Inhibitor (VCI) packets that protect against environmental contaminants and humidity that aggressively corrode metal parts, components, electronics, and electrical components/equipment