Selecting the right rust preventative for heavy castings in warehouse storage is critical. This is because large steel and cast-iron components face elevated corrosion risk during long idle periods. Their mass, complex geometries, and extended exposure to fluctuating warehouse humidity make them especially vulnerable to moisture accumulation and oxygen-driven corrosion.

When heavy castings or large machinery remain in warehouse storage for 12 months or longer, manufacturers should treat corrosion prevention as a system rather than relying on a single product. Furthermore, ZERUST® recommends combining Axxanol™ rust preventative coatings with proper surface preparation and Vapor Corrosion Inhibitor (VCI) technology. This delivers reliable, long-term protection.

Long-term rust preventative coatings for heavy castings in warehouse environments

For these applications, the most effective rust preventative for heavy castings in warehouse storage is a long-term, indoor-rated coating designed to withstand humidity for 6 to 12 months or longer. In addition, ZERUST® Axxanol™ A35-8030 is a proven solution for large castings and industrial machinery. It offers up to 5 years‡ of corrosion protection in controlled indoor environments.

This oil-based rust preventative forms a thin, water-repellent barrier that isolates metal surfaces from moisture and oxygen. Despite its durability, the coating remains easy to remove prior to machining, assembly, or commissioning. When removal is required, it can be efficiently cleaned using ZERUST® AxxaWash™ industrial cleaning products or standard commercial alkaline or solvent cleaners.

Long-Term Rust Preventative for Heavy Castings

ZERUST® Axxanol™ A35-8030 provides up to 5 years‡ of indoor corrosion protection for heavy castings and machinery stored in warehouse environments.

Application best practices for rust preventative performance on heavy castings

Proper application directly impacts performance and service life. Before applying any rust preventative, all metal surfaces should be clean, dry, and free of rust, machining fluids, or debris. Consequently, residual contaminants can trap moisture and reduce protection effectiveness.

Apply the rust preventative by brushing, spraying, or dipping, ensuring full coverage of all exposed surfaces. Additionally, pay special attention to crevices, threads, bolt holes, internal cavities, and machined faces. For large or complex castings where direct coating contact may be limited, ZERUST® also offers VCI-enhanced rust preventative oils. Examples are Axxanol™ 750 and Axxanol™ 758. Furthermore, these products provide dual protection by combining a contact barrier with vapor-phase corrosion inhibitors. These inhibitors migrate into recessed or hard-to-reach areas.

VCI-Enhanced Rust Preventative for Heavy Castings

ZERUST® Axxanol™ 758 combines a protective oil barrier with Vapor Corrosion Inhibitor technology to protect heavy castings and complex machinery in warehouse storage, including hard-to-reach internal surfaces.

Using VCI packaging to enhance rust preventative protection for heavy castings

In warehouse environments with variable humidity, airborne contaminants, or seasonal temperature swings, additional packaging measures further reduce corrosion risk. After coating, heavy castings or machinery can be wrapped or enclosed in ZERUST® ICT® VCI film or bags. This helps protect uncoated surfaces and maintains a corrosion-inhibiting atmosphere around the component.

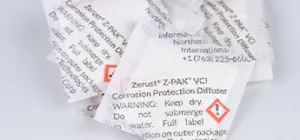

For extended storage or sensitive equipment, protection can be enhanced by adding ZERUST® ActivPak® or Z-PAK® emitters, and ZERUST® ActivDri™ PWA Moisture Control Packets inside the enclosure. These components actively control residual humidity. In addition, they reinforce vapor-phase corrosion protection throughout the storage period.

System-based corrosion protection for warehouse storage

By integrating Axxanol™ rust preventative coatings, AxxaWash™ cleaning solutions, and ICT® VCI packaging technologies, ZERUST® delivers a comprehensive corrosion protection system for heavy castings and machinery in indoor warehouse storage. This system-based approach is supported by the Z-CIS® (Corrosion Inhibiting System) methodology. As a result, it minimizes rework, reduces maintenance costs, and keeps equipment ready for future use or shipment.

For application-specific guidance, manufacturers can contact ZERUST®/EXCOR® to speak with a technical service representative and identify the most effective rust preventative for heavy castings in warehouse storage.

Speak with a Corrosion Protection Expert

Every storage environment presents unique corrosion risks. Contact ZERUST® to discuss your heavy castings, warehouse conditions, and storage duration with a corrosion expert who can recommend a system-based solution.