The most effective way to protect bare steel parts during sea freight is to use a system-based corrosion protection strategy. This strategy addresses moisture, salt exposure, and temperature fluctuations throughout the journey. Ocean shipping environments are extremely aggressive due to high humidity, salt-laden air, and rapid temperature swings inside containers. These conditions frequently lead to condensation, also known as container rain, which causes bare steel to rust quickly if not properly protected.

ZERUST®/EXCOR® provides an integrated corrosion control approach that combines temporary corrosion-preventive coatings, VCI packaging materials, and moisture-control technologies. When used together, these solutions help ensure bare steel parts arrive at their destination clean, dry, and corrosion-free.

Apply a corrosion preventive coating as the first layer of protection

A critical first step to protect bare steel parts during sea freight is applying a temporary corrosion preventive coating. ZERUST® Axxanol™ rust preventive coatings create a protective barrier that shields steel surfaces from moisture and corrosive contaminants.

Light oil-based coatings such as Axxanol™ 33, A35-8030, and A35-30 form thin, water-repellent films. These films protect machined steel components while remaining easy to remove before assembly. For longer voyages, outdoor exposure, or extended storage, heavier grease-type coatings such as Axxanol™ Spray-G and Axxanol™ Z-Maxx provide enhanced barrier protection.

When steel parts include complex geometries, internal cavities, threads, or enclosed spaces, VCI oils such as Axxanol™ 750 and 758 offer added protection. These products combine a surface film with vapor corrosion inhibitors that migrate into hard-to-reach areas where contact coatings cannot reach.

Use VCI packaging to maintain a protective atmosphere and protect bare steel parts during sea freight

The next line of defense is VCI packaging, which helps maintain a corrosion-inhibiting environment throughout transit. Use ZERUST® VCI films, bags, and papers to fully wrap bare steel parts, minimize air exchange, and trap protective VCI vapors around the metal surfaces.

Place ZERUST® ZDC® desiccants inside the packaging to absorb residual humidity and further reduce corrosion risk. Proper sealing is essential, as it allows the VCI molecules to remain concentrated and effective for the duration of the sea journey. When combined, VCI packaging and desiccants provide robust protection against corrosion during long-distance ocean transport.

Control moisture and condensation inside shipping containers to protect bare steel parts during sea freight

Even well-packaged parts can corrode when moisture inside the shipping container remains uncontrolled. Temperature changes during sea freight often cause condensation to form on container walls and ceilings, creating container rain that drips onto cargo.

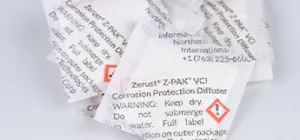

To mitigate this risk, ZERUST® ZDC® desiccants or ActivDri™ PWA moisture-control packets can be installed inside containers to absorb excess humidity. For enclosed spaces, crates, or electrical compartments, ZERUST® VCI emitters such as ActivPak® or Z-PAK® provide additional vapor-phase corrosion protection. Containers should always be loaded under dry conditions, with no standing water present before sealing.

Add Active Moisture Control with ActivDri™ PWA Packets

For added protection against condensation and container rain during ocean transit, ZERUST® ActivDri™ PWA moisture-control packets absorb excess humidity. They also provide vapor-phase corrosion protection inside shipping containers.

Example application for shipping bare steel by sea

For a typical shipment of machined bare steel components transported by sea for four to six weeks, ZERUST® recommends thoroughly cleaning and drying all parts to remove machining fluids and residues. A light coat of Axxanol™ rust preventative oil should then be applied. Each component can be wrapped in ZERUST® ICT® VCI paper or sealed in a VCI bag, packed into a wooden crate lined with ZERUST® VCI film, and supplemented with ZDC® desiccant packs before final closure.

A proven system to protect bare steel parts during sea freight

By combining Axxanol™ corrosion preventive coatings, ICT® VCI packaging, and moisture-control technologies, ZERUST® delivers a proven, system-based solution to protect bare steel parts during sea freight. This approach, supported by the ZERUST® Z-CIS® (Corrosion Inhibiting System) methodology, helps manufacturers reduce rust claims, avoid costly rework, and prevent shipping delays. For application-specific guidance, manufacturers can contact ZERUST®/EXCOR® to speak with a technical service representative.

Get Application-Specific Guidance from ZERUST®

Every shipment presents unique corrosion risks. ZERUST® technical service experts help you design a system-based solution to protect bare steel parts during sea freight based on transit time, packaging method, and environmental exposure.