Yes. ZERUST® provides a broad selection of water-based rust inhibitors under the Axxatec™ portfolio. These products are specifically formulated for use in rinse tanks and final-stage rinse applications following metal part washing.

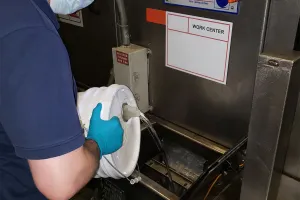

A properly selected product for rinse tanks plays a critical role in preventing flash rust and short-term corrosion immediately after parts leave the wash stage. At this point in the process, freshly cleaned metal surfaces are highly reactive and vulnerable to oxidation. This is due to residual moisture, temperature fluctuations, and ambient humidity. ZERUST® Axxatec™ inhibitors are engineered to address this risk directly within aqueous systems.

When selecting a water-based rust inhibitor for rinse tanks, products such as Axxatec™ 80C, 30C, and 48C deliver reliable corrosion protection while maintaining compatibility with automated and manual rinse operations. These inhibitors form a thin, uniform protective film on metal surfaces that actively interrupts the corrosion process without leaving oily residues or interfering with downstream operations such as coating, painting, or assembly.

Need Help Preventing Flash Rust in Your Rinse Process?

ZERUST® technical experts can help you select the right water-based rust inhibitor for your rinse tanks based on your metals, soils, and protection requirements.

Dual-Action Water-Based Rust Inhibitor for Rinse Tanks

In addition to dedicated inhibitors, ZERUST® offers dual-action water-based rust inhibitors that also function as cleaners, allowing manufacturers to streamline their production processes by combining cleaning and corrosion protection into a single step.

The Axxatec™ Dual-Action Products, including DA-23C, DA-24C, and DA-40AL, remove light soils and contaminants while simultaneously depositing a corrosion-inhibiting layer. This approach reduces chemical handling, lowers water consumption, and improves overall process efficiency while maintaining consistent corrosion protection in rinse tanks.

Selecting the Water-Based Rust Inhibitor for Your Rinse Tank

The optimal solution depends on several key factors, including:

- The type and amount of soil being removed

- The metal composition of the parts

- Desired protection duration

- Rinse tank design and operating conditions

- Compatibility with downstream processes

ZERUST® engineers its Axxatec™ portfolio to support a wide range of metals and operating environments, making it easier to integrate corrosion protection without disrupting existing workflows.

Explore ZERUST® Corrosion Inhibitor Solutions

For deeper technical details, product comparisons, and application guidance, explore the ZERUST® Corrosion Inhibitor Liquids, Additives, and Rust Removers Brochure.

Get expert support for your application

If you need help selecting the best water-based rust inhibitor for rinse tanks in your facility, ZERUST®/EXCOR® technical service representatives can evaluate your process and recommend a tailored solution that aligns with your corrosion risks, production goals, and sustainability objectives.