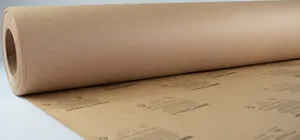

How to use VCI paper correctly is essential for achieving reliable, residue-free corrosion protection during storage and shipment. When applied properly, ZERUST ICT® VCI paper releases corrosion-inhibiting vapors that form a protective molecular layer on metal surfaces, shielding them from moisture, oxygen, and other corrosive elements.

Below is a step-by-step guide and best practices to ensure optimal results.

|

|

|

|

|

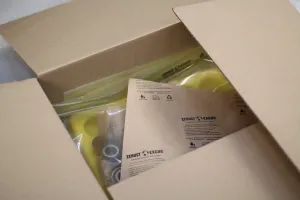

Use a Fully Enclosed PackageVCI paper works best inside a sealed environment. After wrapping or interleaving parts, place them inside a fully enclosed poly bag, box, crate, or container. Sealing the enclosure helps maintain the proper vapor concentration needed for effective corrosion protection. |

|

|

Start With Clean, Dry Metal PartsBefore using, always ensure metal parts are clean and visibly dry. Dirt, machining residues, salts, or standing water can interfere with corrosion protection. However, parts coated with compatible oil-based rust preventatives may still be packaged with VCI paper, as these products work together to enhance protection. |

|

|

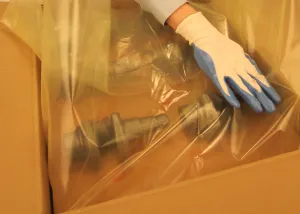

Handle Parts With Clean, Dry GlovesAlways wear clean, dry gloves when handling metal components. Fingerprints can transfer salts and moisture onto metal surfaces, which may lead to corrosion even inside protected packaging. |

|

|

Never Reuse Damaged or Contaminated VCI PaperFor best results, avoid reusing old, torn, dirty, or contaminated VCI paper. Once compromised, the paper may no longer release sufficient inhibitors to protect metal surfaces. |

|

|

Wrap or Interleave PartsWrap each metal component directly with VCI paper or, for stacked parts, interleave one sheet between every layer. This placement allows corrosion-inhibiting vapors to reach all exposed metal surfaces evenly. For complex shapes or tightly nested parts, ensure the paper maintains close proximity to the metal for faster vapor activation. |

|

|

Avoid Blocking VCI Vapor FlowDo not place non-VCI materials, such as plastic sheets, foams, or liners, between the VCI paper and the metal. These materials can block vapor contact and reduce protection effectiveness. |

Best Practices for Long-Term Protection

To maximize performance:

- Seal packages tightly to prevent vapor loss

- Store packaged parts in a covered, dry area

- Minimize package openings

- Match the VCI paper type to the metal being protected

Download ZERUST®’s How to Use VCI Paper Correctly guide to ensure proper application and maximum corrosion protection.

Why Proper Use Matters

Using VCI paper correctly helps prevent flash rust, reduces rework, and keeps metal parts clean and ready for use, without oils, greases, or cleanup. As a result, manufacturers gain reliable corrosion protection while maintaining efficient packaging and handling processes.

Contact ZERUST® to get personalized recommendations on corrosion protection solutions tailored to your metals, environment, and storage or shipping requirements.