Protecting electrical or control-panel enclosures from corrosion requires controlling moisture and airborne contaminants inside the enclosure while using corrosion-inhibiting solutions that are safe for sensitive electrical components. When done correctly, it is possible to protect electrical enclosures from corrosion without affecting conductivity, insulation, or system performance.

ZERUST® offers corrosion solutions specifically engineered for electrical and electronic enclosures. These products rely on non-conductive, non-hardening protection methods that do not interfere with normal operation or require removal before service.

As a result, the most effective approach combines direct metal protection with vapor-phase corrosion inhibitors that work throughout the enclosure.

How ZERUST® solutions protect electrical enclosures from corrosion

To protect electrical enclosures from corrosion, ZERUST® solutions focus on two key mechanisms: thin-film surface protection and vapor corrosion inhibition.

Axxanol™ 718-ESS provides direct protection by forming a thin, water-displacing, non-staining, non-hardening film on exposed metal surfaces. This film shields terminals, connectors, bus bars, junction boxes, and cabinet interiors while maintaining electrical resistance and mechanical function.

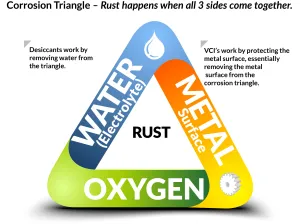

For enclosed or hard-to-reach areas, ZERUST® VCI emitters release corrosion-inhibiting molecules into the airspace. Furthermore, these molecules migrate throughout the enclosure and bond to metal surfaces without coating components or leaving residue.

Vapor corrosion inhibitors for protecting electrical enclosures from corrosion

VCI emitters are ideal when users need to protect electrical enclosures from corrosion without spraying or coating sensitive components. Common ZERUST® options include:

- Vapor Capsules and ZAK-M22 Capsules

- ActivDri™ moisture-control packets

- ICT® Plastabs®

- ActivTab™(LS) tablets

- ActivCapsule™ FAC1-1(S)

- Cor Tab® tablets

These products protect metal surfaces inside sealed or semi-sealed enclosures, including fasteners, mounting rails, hinges, and grounding points. Furthermore, they are safe for use around metals, plastics, elastomers, insulation materials, and painted surfaces commonly found in electrical equipment.

Vapor corrosion inhibitors for protecting electrical enclosures from corrosion

Explore ZERUST® VCI emitters designed to protect electrical enclosures from corrosion without affecting sensitive components or performance.

Best practices to protect electrical enclosures from corrosion

Following proper application steps ensures long-term performance and reliability.

Step 1: Clean and dry internal surfaces

Remove dust, oxidation, oils, and contaminants before applying any corrosion protection. Moisture and residues reduce protection effectiveness.

Step 2: Apply thin-film protection where needed

Apply only a thin, even layer of Axxanol™ 718-ESS to exposed metal surfaces. Avoid excess buildup near relays, sensors, or airflow paths.

Step 3: Install VCI emitters correctly

Mount or place VCI capsules or tablets according to ZERUST® installation guidance. Ensure vapor molecules can circulate freely throughout the enclosure.

Step 4: Maintain airflow and service access

Do not block cooling paths, vents, or moving components. Proper airflow supports both corrosion control and thermal management.

How often should electrical enclosures be inspected for corrosion?

Even when systems are protected, periodic inspection is recommended. In most environments, inspections every 6 to 12 months are sufficient. In harsh conditions such as coastal locations, chemical plants, wastewater facilities, or high-humidity areas, more frequent checks may be required.

Routine inspections help confirm that corrosion protection remains active and that VCI emitters are replaced at the recommended intervals.

Why a combined approach works best

The most reliable way to protect electrical enclosures from corrosion is to combine direct metal protection with vapor-phase corrosion inhibitors. Thin-film protection guards exposed surfaces, while VCI technology protects internal cavities and hidden metal areas.

This layered approach helps extend equipment life, reduce downtime, and maintain electrical reliability without altering system performance.

For application-specific guidance, users can contact ZERUST®/EXCOR® to speak with a technical service representative and develop a corrosion prevention strategy tailored to their environment.

Need help protecting against corrosion?

ZERUST® technical service experts can help you select the right vapor corrosion inhibitors and protective solutions for your electrical or control panel environment.