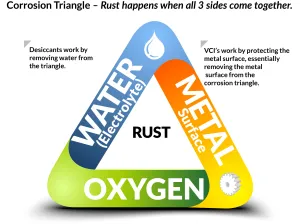

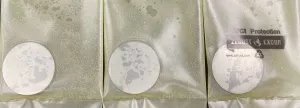

Can VCI bags be used with oil coatings is a common question, and in many applications, the answer is yes when the oil coating is applied correctly. A light oil coating on the metal surface is generally compatible with ZERUST® VCI bags and VCI film. However, heavy or excessive oil coatings can reduce the effectiveness of vapor corrosion inhibitor technology. The excessive coating limits how VCI molecules interact with the metal surface.

Understanding how oil thickness, application method, and storage conditions interact with VCI technology helps ensure reliable corrosion protection.

Selecting the right rust preventative coating

Heavy oil coatings can impact VCI performance. Explore ZERUST® rust inhibitors and preventative coatings designed to work with VCI packaging systems.

Can VCI bags be used with oil coatings if the oil layer is heavy?

In these cases, performance may be reduced. Thick oil films can act as a physical barrier, preventing VCI molecules from reaching the metal surface. When this occurs, the vapor phase protection may be incomplete or uneven.

Heavy oil coatings are more likely to cause issues in long-term storage, export packaging, or high-humidity environments where uniform vapor coverage is critical.

Best practices when combining protection types

Maximize protection by following these best practices when using VCI bags with oil coatings:

- Apply oil in a thin, even layer and avoid pooling or overcoating

- Allow excess oil to drain before packaging

- Ensure the part surface is clean and free of corrosive residues

- Fully seal the VCI bag to maintain an enclosed vapor environment

- Match the oil type and VCI material to the metal and exposure conditions

These steps help ensure both the oil and the VCI technology work together rather than interfering with one another.

When should you consult ZERUST®?

Because oils vary widely in formulation, viscosity, and additives, using VCI bags with oil coatings is not always a one-size-fits-all answer. Certain oils, especially those with strong polar additives or heavy wax components, may affect vapor migration differently.

For this reason, ZERUST® recommends contacting a corrosion expert to evaluate the specific oil, application thickness, metal type, and storage environment. Product testing or alternative protection strategies may be recommended to ensure long-term corrosion control.

In summary, VCI bags can be used with oil coatings when the oil is applied lightly and correctly. Light oil films generally work well alongside ZERUST® VCI technology, while heavy coatings may limit vapor access to the metal surface. Proper application, sealing, and product selection are key to achieving reliable corrosion protection.

For application-specific guidance, ZERUST® technical experts can help determine the best combination of oil coatings and VCI packaging for your operation.

Need help selecting the right VCI and coating solution?

ZERUST® corrosion experts can help you determine the best combination of VCI bags, oil coatings, and rust preventatives for your application and environment.