We are commonly asked, can VCI bags be reused? In many cases, the answer is yes when the bags remain dry, clean, and structurally sound. ZERUST®/EXCOR® VCI film and bags continue to release corrosion-inhibiting vapor as long as the material is intact and has not been contaminated or degraded.

Reusing VCI bags can help reduce packaging waste and costs, but proper inspection is critical to ensure continued corrosion protection.

When can VCI bags be reused safely?

VCI bags can be reused when they meet the following conditions:

- The bag is clean and free of dirt, oil buildup, or corrosive residues

- The bag is completely dry, with no trapped moisture or condensation

- The film remains flexible and has not become brittle

- There are no large holes, tears, or weakened seams

Small pinholes or minor punctures can often be sealed with adhesive tape without significantly reducing protection. Once resealed, the VCI environment inside the bag can still protect metal surfaces.

Can they be reused after damage or UV exposure?

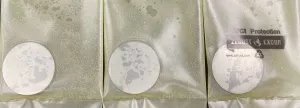

No. Not if the material has lost its integrity. VCI bags should not be reused if they show signs of:

- Large holes or tears that cannot be fully sealed

- Cracking or brittleness caused by prolonged exposure to direct sunlight

- Loss of strength or flexibility

- Heavy contamination from oils, salts, or chemicals

Damaged or degraded VCI bags allow excessive air exchange. This prevents VCI vapors from maintaining a protective concentration and significantly increases corrosion risk.

Not sure if your bags can be reused?

Speak with a ZERUST® corrosion expert to determine whether damaged or UV-exposed bags can still provide reliable corrosion protection.

How does reuse affect corrosion protection performance?

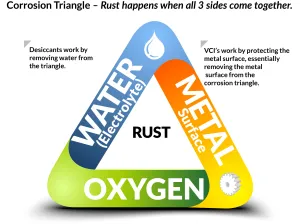

VCI technology works by creating a protective vapor-phase environment around metal surfaces. As long as the enclosure remains intact, reused VCI bags can continue to provide effective corrosion protection.

However, reused bags may offer reduced protection life compared to new packaging. Environmental conditions such as humidity, storage duration, and handling frequency also influence performance. For long-term storage, export shipments, or harsh environments, new VCI bags are typically recommended.

Best practices if you plan to reuse VCI bags

If you choose to reuse VCI bags, follow these best practices to maintain protection:

- Inspect each bag thoroughly before reuse

- Allow bags to fully dry before inserting metal parts

- Reseal all seams and small punctures tightly

- Avoid reusing bags that were stored outdoors or exposed to UV light

- Replace bags used in severe or high-humidity environments

For critical components, high-value parts, or extended storage periods, consult ZERUST® technical experts to confirm whether reuse is appropriate.

Need help selecting the right corrosion protection solution?

ZERUST® corrosion experts can help you determine whether VCI bags can be reused and recommend the best protection strategy for your storage or shipping conditions.