Are rust inhibitors safe for ferrous and non-ferrous metals?

Yes, selecting the correct rust inhibitor formulation allows safe protection of both ferrous and non-ferrous metals. ZERUST® rust inhibitors are designed to protect a wide range of metals, including:

- Carbon steel and cast iron

- Aluminum and aluminum alloys

- Copper and copper alloys

- Brass

- Zinc and galvanized surfaces

However, are rust inhibitors safe for all metal types in every situation? The answer depends on the inhibitor chemistry and the metal being protected. Some inhibitors optimized for steel may not be suitable for yellow metals or sensitive aluminum alloys.

Explore ZERUST® rust inhibitors for your metal and process

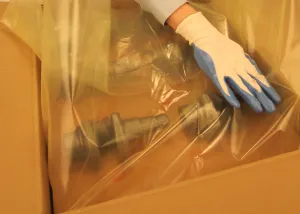

Compare oil based, water based, solvent based, and other rust preventatives and coatings designed to protect ferrous and non ferrous metals.

Rust inhibitors for multimetal assemblies

Multimetal assemblies present a higher corrosion risk due to galvanic interactions between dissimilar metals. In these cases, using a rust inhibitor for multimetal assemblies is essential.

Multimetal-compatible rust inhibitors protect dissimilar metals within the same enclosure, container, or shipment. These solutions help reduce galvanic corrosion while maintaining surface integrity across all components.

Why not all rust inhibitors are safe for every metal

Although rust inhibitors are highly effective, not every product works across all metals. Using an incompatible inhibitor can lead to:

- Reduced corrosion protection

- Surface staining or discoloration

- Chemical incompatibility with certain alloys

- Long-term surface degradation

This reinforces why “are rust inhibitors safe for all metal types” is a question that should be answered on a product-by-product basis.

How to choose the right rust inhibitor for your metal type

To ensure safe and effective corrosion protection:

- Identify the specific metal or metals you are protecting

- Evaluate exposure conditions such as humidity, storage duration, and shipment environment

- Review Technical Data Sheets for metal compatibility

- Consult corrosion experts for multimetal or critical applications

Selecting the correct rust inhibitor ensures compatibility, performance, and long-term protection.

So, are rust inhibitors safe for all metal types?

They can be, but only when the proper formulation is selected. Choosing a rust inhibitor specifically designed for your metal or combination of metals is the best way to achieve reliable corrosion protection without unintended side effects.

Get expert help choosing the right rust inhibitor

Work directly with ZERUST® corrosion specialists to select the most effective rust inhibitor for your metal type, application, and exposure conditions.