In today’s industrial landscape, the pressure to meet operational standards while adhering to evolving environmental regulations has never been greater. As a result, manufacturers and facility managers reassess their cleaning processes. One critical comparison has emerged: Water-Based Degreasers vs Solvent-Based. Which option delivers the best results while maintaining compliance, safety, and sustainability?

In today’s industrial landscape, the pressure to meet operational standards while adhering to evolving environmental regulations has never been greater. As a result, manufacturers and facility managers reassess their cleaning processes. One critical comparison has emerged: Water-Based Degreasers vs Solvent-Based. Which option delivers the best results while maintaining compliance, safety, and sustainability?

In this blog, we’ll first break down the key differences between water-based and solvent-based degreasers. Then, we’ll examine why water-based solutions have surged in popularity. Finally, we’ll introduce ZERUST® AxxaWash™, a line of water-based cleaners and degreasers engineered for superior industrial performance.

Understanding the Fundamentals: Water-Based Degreasers vs Solvent-Based

What Are Solvent-Based Degreasers?

Solvent-based degreasers rely on petroleum or chlorinated solvents to dissolve organic contaminants such as heavy oils, greases, and adhesives. As a result, their non-polar chemical structure makes them highly effective at dissolving hydrocarbons quickly.

|

Common Applications:

|

Key Characteristics:

|

However, it’s important to note that solvent-based degreasers do not effectively remove inorganic soils such as rust, oxides, and scale because their chemistry targets organic contaminants. Consequently, these substances do not dissolve in solvents. In contrast, many water-based cleaners break down both hydrocarbon and inorganic soils, which makes them a more versatile solution for industrial cleaning applications with mixed contaminants.

What Are Water-Based Degreasers?

In contrast, Water-based degreasers utilize water as the primary carrier, combined with surfactants, detergents, builders, and corrosion inhibitors to lift and emulsify soils. Additionally, modern formulations are often tailored to match the performance of solvents with improved safety and environmental compatibility.

|

Common Applications:

|

Key Characteristics:

|

Water-Based Degreasers vs Solvent-Based: A Side-by-Side Comparison

| Criteria | Water-Based Degreasers | Solvent-Based Degreasers |

|---|---|---|

| Cleaning Strength | Effective on light to moderate oils and particulates | Highly effective on heavy hydrocarbons, adhesives, and waxes |

| Environmental Impact | Low VOCs, biodegradable, and easier wastewater treatment | High VOCs, hazardous disposal requirements |

| Worker Safety | Non-flammable, low odor, fewer respiratory risks | Flammable, toxic vapors, requires strict PPE use |

| Cost Considerations | Lower chemical costs | Higher chemical cost |

| Surface Compatibility | Safe for metals, plastics, and painted surfaces | May damage sensitive materials; solvent residue risk |

| Regulatory Compliance | More likely to comply with VOC, REACH, and EPA regulations | Increasing restrictions in many regions |

Why Water-Based Degreasers Are Gaining Momentum

The shift toward water-based degreasing is more than a trend; it’s a response to tightening regulations, corporate sustainability goals, and advances in chemical technology. As a result, here’s why industries are making the switch:

- Environmental Sustainability: Water-based degreasers contain little to no volatile organic compounds (VOCs), significantly reducing air pollution and improving workplace air quality. Therefore, they support both regulatory compliance and long-term sustainability initiatives.

- Safer Work Environments: Without the fire hazards, strong odors, or skin/eye irritation risks associated with solvent-based chemicals, water-based products enhance employee safety. Moreover, they reduce the burden of compliance with hazardous material handling regulations.

- Cost-Effective Over Time: Although aqueous systems may require heating or agitation, the reduced chemical usage, easier disposal, and extended equipment life can lower long-term costs. Consequently, many operations experience a positive return on investment.

- Modern Chemical Formulations:Today’s water-based degreasers, such as those in ZERUST’s AxxaWash™ line, deliver cleaning performance that rivals many solvent-based options. In particular, they excel in removing light to moderate hydrocarbon soils without compromising safety.

When to Choose Solvent-Based Degreasers

Solvent-based degreasers still hold an advantage in niche applications where:

- Cleaning speed is critical

- Moisture exposure must be avoided (e.g., electronics)

- Heavily carbonized or baked-on soils are present

However, solvent use demands greater precautions due to flammability, VOC emissions, and regulatory constraints.

ZERUST® AxxaWash™: Comprehensive Water-Based Cleaning & Inhibition

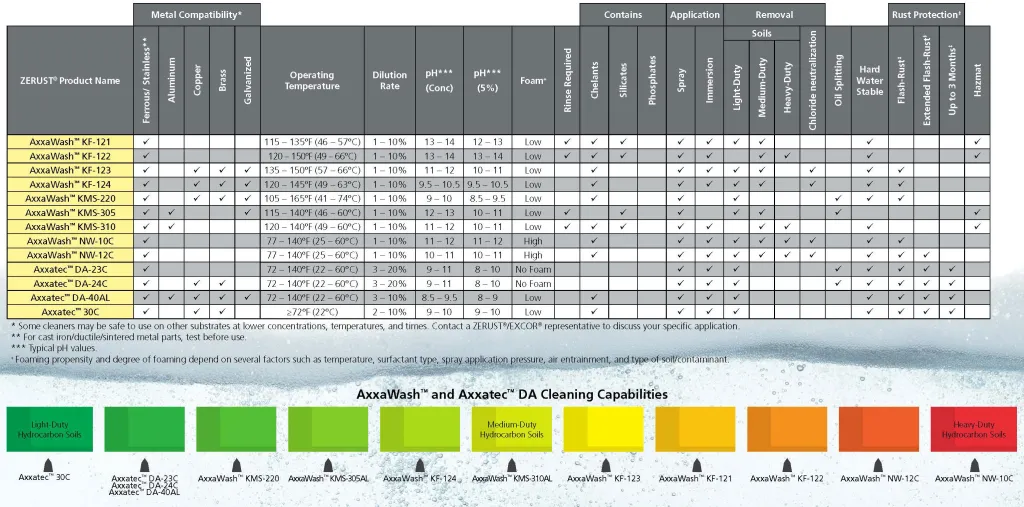

Specifically, ZERUST’s AxxaWash™ product family offers a wide range of water-based industrial degreasers engineered for various cleaning systems, soil types, and substrates. Each solution is carefully formulated to deliver powerful cleaning action while protecting against flash rust and ensuring downstream corrosion control compatibility.

Key Benefits Across the AxxaWash™ Line

- Effective cleaning of oils, greases, and particulates

- Low-VOC, non-flammable, biodegradable formulations

- Surface-safe for aluminum, steel, ferrous & non-ferrous metals

- Integrated flash-rust inhibition

- Compliant with global environmental and safety regulations

ZERUST® AxxaWash™ Product Line Overview

KF‑123

- Low foam above 135°F (57°C)

- Mild alkaline cleaner

- Hard-water compatible

- Reduces flash-rust

- Removes light to medium-duty hydrocarbon soils on ferrous substrates while offering chloride mitigation

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, silicates, or solvent

- Can be used in immersion, ultrasonic, spray, and drum washer processes

KMS‑220

- Low foam above 105°F (41°C)

- Mild alkaline cleaner

- Low application temperature 105 – 165°F (41 –74°C)

- Excellent oil-splitting capabilities and flash-rust inhibition

- Removes light-duty hydrocarbon soils and particulates on ferrous substrate

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, silicates, or solvent

- Can be used in spray processes. Do not use in immersion processes

KF‑124

- Low foam above 120°F (49°C)

- Mild alkaline cleaner

- Low application temperature 120 – 145°F (49 – 63°C)

- Hard-water compatible and flash-rust inhibition

- Removes light to medium-duty hydrocarbon soils on ferrous substrates while offering chloride mitigation

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, silicates, or solvent

- Can be used in immersion, ultrasonic, spray, and drum washer processes

NW‑10C

- Hard-water compatible

- Mild alkaline cleaner

- Wide application temperature range 77 – 140°F (25 – 60°C)

- Flash-rust inhibition

- Removes sources of corrosion such as chlorides, oils, and contaminants on ferrous substrates

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, or silicates

- Can be used in immersion, ultrasonic, and spray processes. Product foams when used in spray mode. Contact your ZERUST® for recommendations on suitable defoaming agents.

KF‑121

- Low foam above 115°F (46°C)

- Heavy-duty alkaline cleaner

- Hard water-compatible

- Low operating temperatures 115 – 135°F (46 – 57°C)

- Removes light to medium-duty hydrocarbon soils on ferrous substrates

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, or solvent

- Can be used in immersion, ultrasonic, spray, and drum washer processes

NW‑12C

- Hard-water compatible

- Mild alkaline cleaner

- Wide application temperature range 77 – 140°F (25 – 60°C)

- Flash-rust inhibition

- Removes oily contaminants and deactivates corrosion-inducing inorganic anions on ferrous substrates

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, or silicate

- Can be used in immersion, ultrasonic, and spray processes.

KMS‑305AL

- Low foam above 115°F (46°C)

- Alkaline cleaner

- Superb oil-splitting capabilities

- Low operating temperatures 115 – 135°F (46 – 57°C)

- Removes light to medium-duty hydrocarbon soils and particulates on aluminum, ferrous, and galvanized substrates.

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, or solvent

- Can be used in spray processes. Do not use in immersion processes.

KF‑122

- Low foam above 120°F (49°C)

- Heavy-duty alkaline cleaner

- Hard-water compatible

- Wide application temperature range 120 – 150°F (49 – 66°C)

- Removes medium to heavy-duty hydrocarbon soils on ferrous substrates

- Does not contain solvents or phosphate

- Can be used in immersion, ultrasonic, spray, and drum washer processes

KMS‑310AL

- Low foam above 120°F (49°C)

- Alkaline cleaner

- Hard-water compatible

- Low application temperature 120 – 140°F (49 – 60°C)

- Remove medium to heavy-duty soils from aluminum and ferrous alloys

- Does not contain alkylphenol ethoxylates, boron salts, phosphates, solvents, or VOC

- Can be used in immersion, ultrasonic, spray, and drum washer processes.

AxxaWash™ Product Selection Guide

Water-Based Degreasers vs Solvent-Based: Which Cleaner Is Right for You?

The choice between water-based degreasers vs solvent-based solutions depends on your specific application, compliance requirements, and environmental strategy. While solvents still serve limited, critical-use cases, modern water-based degreasers, especially ZERUST® AxxaWash™ products, are rapidly becoming the industry standard.

With AxxaWash™, you gain:

- Proven industrial cleaning performance

- Safer workplace conditions

- Streamlined environmental compliance

- Seamless integration with corrosion protection protocols

Request a Product Match or On-Site Demo

Ready to replace or upgrade your current cleaning system? Contact ZERUST® today to identify the optimal AxxaWash™ solution for your metalworking, preservation, or general industrial cleaning needs.