To protect steel components in an unheated warehouse, manufacturers need a corrosion control strategy that accounts for moisture, condensation cycles, and temperature swings. Even though parts are stored indoors, unheated warehouses frequently experience dew point fluctuations that allow condensation to form on steel surfaces. Furthermore. without proper protection, this moisture can quickly initiate corrosion.

ZERUST® addresses these risks with a system-based approach that combines environmental control, rust preventative coatings, and ICT® Vapor Corrosion Inhibitor packaging to protect steel throughout storage.

Why it is difficult to protect steel components in an unheated warehouse

Unheated warehouses are especially challenging environments for steel storage. Consequently, temperature changes between day and night can cause warm, moist air to condense on cooler metal surfaces. Over time, these repeated condensation cycles accelerate oxidation.

Common risk factors include:

- Seasonal humidity swings

- Poor air circulation

- Cold floors and exterior walls

- Contaminants such as dust, salts, and acids

These conditions make it essential to protect steel components in an unheated warehouse using more than a single corrosion prevention method.

Environmental controls to help protect

Environmental controls are the first line of defense. While they cannot eliminate corrosion risk on their own, they significantly improve overall protection.

Best practices include:

- Increase airflow to reduce stagnant air pockets

- Store components off the floor using racks or pallets

- Avoid placing steel directly against exterior walls

- Minimize rapid temperature changes when possible

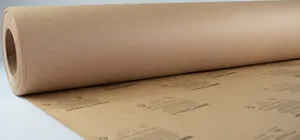

Wooden pallets can introduce additional risk because they emit acids and retain moisture. When steel must be stored on wood, always isolate it using ZERUST® ICT® VCI paper or sealed ICT® VCI bags.

If relative humidity regularly exceeds 50%, place an ActivDri™ PWA Packet inside the VCI enclosure to absorb excess moisture and reduce condensation risk.

Learn how wood and pallets can accelerate corrosion

Wooden pallets and dunnage can emit acids and retain moisture that increase corrosion risk during indoor storage. Learn how ZERUST® VCI packaging helps isolate steel components and eliminate corrosion caused by wood-based materials.

Rust preventative coatings to protect steel components in an unheated warehouse

Applying a rust preventative coating creates a physical barrier between steel and moisture. Furthermore, the correct coating depends on storage duration and environmental severity.

Recommended options include:

- Short-term indoor storage: Axxanol™ 33 provides a thin, water-repellent oil film that resists humidity-driven corrosion.

- Medium to long-term storage: Axxanol™ Spray-G and Axxanol™ Z-Maxx offer grease-based protection for extended exposure and fluctuating humidity.

These coatings remain stable during temperature swings and can be removed easily with ZERUST® AxxaWash™ industrial cleaners or standard alkaline wash systems.

Explore ZERUST® rust preventative coatings

ZERUST® rust preventative coatings are engineered to protect steel components stored in unheated warehouses where condensation and humidity fluctuations increase corrosion risk. Find oil-based, grease-based, and water-based solutions designed for short- and long-term indoor storage.

Using VCI packaging to enhance protection

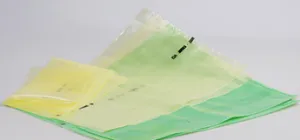

Vapor Corrosion Inhibitor (VCI) packaging technologies add a critical layer of protection in environments where condensation cannot be fully controlled. ZERUST® ICT® VCI paper and VCI film release corrosion-inhibiting molecules that migrate through the enclosed airspace and form an invisible protective layer on metal surfaces.

Key advantages include:

- Protection of exposed and hard-to-reach areas

- Continued corrosion inhibition during humidity fluctuations

- No residue on metal surfaces

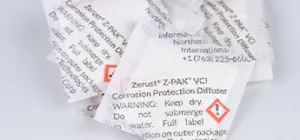

For large enclosures or packaged equipment, ZERUST® VCI emitters such as Vapor Capsules, ActivPak®, or Z-PAK® help maintain a corrosion-inhibiting atmosphere throughout the space.

Always use ZERUST® ICT® VCI film or bags instead of conventional plastic wrap. Standard plastic can trap moisture and worsen corrosion.

Best system-based approach to protect steel components in an unheated warehouse

For maximum reliability, ZERUST® recommends a layered approach:

- Apply an Axxanol™ rust preventative coating when extended storage is expected

- Enclose the component in ZERUST® ICT® VCI packaging

- Add ActivDri™ PWA moisture control if the humidity is high

- Seal packaging tightly to retain VCI molecules

When parts will be painted, welded, or assembled later, VCI-only protection is ideal. ZERUST® VCI products leave no residue and allow components to move directly into production.

Inspection and maintenance for unheated warehouses

Long-term storage requires routine inspection. Check components every one to three months for:

- Signs of condensation

- Coating degradation

- Package integrity

Reapply rust preventatives as needed and document inspection intervals to maintain consistency and traceability.

Proven solution to protect steel components in an unheated warehouse

By combining Axxanol™ rust preventative coatings, ICT® VCI packaging, AxxaWash™ cleaners, and environmental controls, ZERUST® delivers a proven corrosion management system. This approach follows the ZERUST® Z-CIS® Corrosion Inhibiting System methodology and helps reduce rework, downtime, and asset loss.

For application-specific guidance, contact ZERUST® to speak with a technical service representative.

Need help protecting steel components in an unheated warehouse?

Every storage environment presents unique corrosion risks. ZERUST® technical

experts can help you select the right combination of rust preventative coatings,

VCI packaging, and moisture control solutions to protect your steel components

and reduce long-term corrosion costs.