ZERUST® VCI for Shipbuilding Industry

VCI for shipbuilding plays a critical role in preventing corrosion across all phases of vessel development. Marine environments expose ships to salt-laden air, moisture, and extreme humidity, which quickly leads to metal degradation. If left unprotected, this can lead to costly repairs and reduced structural integrity.

Shipbuilders must apply reliable corrosion protection throughout fabrication, storage, global transport, and assembly. Common high-risk areas include void spaces, electrical enclosures, piping systems, engines, and heat exchangers. These components are particularly vulnerable if not adequately protected during critical stages of construction.

ZERUST® understands these challenges and offers solutions that meet the unique needs of shipbuilders. Our products help maintain quality, reduce maintenance costs, and ensure that vessels are operationally ready at every stage.

VCI for Shipbuilding – Engineered Corrosion Protection Solutions

ZERUST® provides the best VCI solutions for corrosion protection in the shipbuilding industry. We design these solutions to address the specific challenges shipbuilders, component manufacturers, and marine engineers encounter. Our advanced Vapor Corrosion Inhibitor (VCI) products safeguard critical metal assets throughout the shipbuilding lifecycle. This includes fabrication, assembly, and commissioning.

We tailor our corrosion protection strategies to deliver long-term, residue-free performance. This approach reduces downtime, maintenance costs, and component failures in marine environments.

Shipboard Void Protection

Shipbuilders can apply VCI emitters and powders in enclosed areas like ballast tanks, compartments, and storage cavities. These products create a protective molecular layer on metal surfaces. As a result, the VCI molecules adsorb onto bare metal surfaces. This forms an invisible shield that prevents the onset of corrosion. ZERUST® products protect void spaces effectively during lay-up, transit, and commissioning. They eliminate the need for disassembly or cleaning after application.

Storage and Shipping

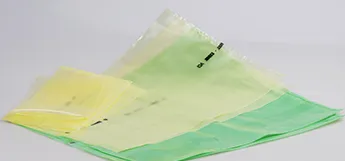

Shipbuilders often store or ship components, like engines, gear assemblies, and electrical boxes, without protection, exposing them to corrosion during transit or storage in shipyards. VCIs integrated into packaging materials such as films, papers, and foam offer passive protection throughout the storage and shipping process. ZERUST® packaging products provide reliable corrosion protection while optimizing logistical efficiency.

Seaworthy Packaging

Marine shipping exposes vessels to extreme environmental conditions, including salt spray, fluctuating humidity, and high condensation levels. ZERUST® offers VCI packaging solutions engineered for harsh environments, providing enhanced barrier properties to safeguard parts during overseas transport or long-term outdoor storage. Whether wrapping entire assemblies or individual components, our VCI for shipbuilding ensures these materials withstand exposure to marine environments, helping prevent corrosion-related damage before final installation.

Maintenance and Repair

Maintenance crews often remove or expose metal parts during both scheduled and emergency services. If stored temporarily, these parts face a high risk of corrosion. ZERUST® provides targeted anti-corrosion solutions for maintenance and repair scenarios, including emitters, sprays, and flexible packaging that ensure in-process and spare components remain corrosion-free. These solutions help maintain the integrity of parts and reduce delays during dry dock operations or system overhauls.

Partner with ZERUST® for Proven Shipbuilding Corrosion Solutions

With decades of expertise in corrosion prevention and a track record of success across global marine industries, ZERUST®/EXCOR® is a trusted partner for shipbuilders seeking reliable, cost-effective protection. Our VCI solutions are engineered to meet the unique demands of the shipbuilding environment—whether for enclosed void spaces, long-distance transport, or in-field maintenance. When you work with ZERUST®/EXCOR®, you gain more than just high-performance products; you gain a team committed to helping you identify the most effective corrosion control strategies for your operations. Contact us today to discover how ZERUST® VCI for shipbuilding can protect your metal assets at every stage of the vessel lifecycle, from assembly to overseas transport.

- Proven rust prevention for ferrous and non-ferrous metals

- Easy-to-apply solutions requiring no surface cleaning after removal

- Non-toxic, residue-free protection is safe for personnel and equipment

- Reduces labor and material costs associated with traditional coatings

- Ensures the reliability of critical components during construction and shipment

- Extends the lifespan of ship components and minimizes downtime

- Compatible with international packaging and transport regulations

- Custom-engineered solutions for unique shipyard and offshore needs