Rust inhibitors are designed to prevent new corrosion, not remove rust that has already formed. If rust develops before applying a rust inhibitor, proper surface preparation is critical to ensure long-term protection and avoid trapping corrosion under the protective layer.

Why Rust Must Be Removed First

Applying a rust inhibitor directly over existing rust can significantly reduce its effectiveness. Furthermore, rust is porous and often retains moisture, salts, and corrosive residues. If these contaminants are sealed in, corrosion may continue beneath the inhibitor and accelerate damage rather than prevent it.

This is why understanding what to do if rust develops before applying a rust inhibitor is essential for effective corrosion control.

Step 1: Remove Existing Rust Completely

If rust is present, it should be fully removed before any inhibitor is applied. Common rust removal methods include:

- Mechanical removal, such as wire brushing, sanding, or blasting

- Chemical rust removers that dissolve corrosion without damaging the base metal

- Rust cleaning solutionsare designed to penetrate cracks, seams, and crevices

Products in the ZERUST® AxxaClean™ series are specifically formulated to remove rust and corrosion residues, even in hard-to-reach areas, helping restore the metal surface for proper protection.

Review how to correctly prepare metal surfaces using ZERUST® rust removers before applying corrosion protection.

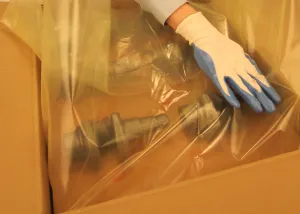

Step 2: Clean and Dry the Metal Surface

After rust removal, the metal must be thoroughly cleaned and visibly dry. Any remaining moisture, cleaner residue, or debris can interfere with inhibitor performance.

This step is critical because even trace moisture left behind can lead to flash rust or reduce the lifespan of the applied rust inhibitor.

Step 3: Apply the Correct ZERUST® Rust Inhibitor

Once the surface is clean and dry, apply a ZERUST® rust inhibitor that matches:

- The metal type

- The storage or operating environment

- The required protection duration

- Compatibility with packaging or downstream processes

At this stage, the inhibitor can form a continuous protective layer that blocks moisture and corrosive agents from reaching the metal surface.

Learn proper application techniques, surface preparation steps, and best practices to maximize protection using ZERUST® rust inhibiting coatings.

What to Do if Rust Appears Before Applying a Rust Inhibitor

If rust appears unexpectedly during storage, handling, or processing, do not apply a rust inhibitor immediately. Instead:

- Stop the corrosion process by removing rust first

- Clean and dry the surface thoroughly

- Reapply protection using a suitable ZERUST® rust inhibitor

Applying inhibitors directly to rusted surfaces can reduce their effectiveness and may trap moisture, actually accelerating corrosion instead of preventing it.

Get detailed guidance on rust removal methods, inhibitor chemistries, and how to choose the right ZERUST® solution for your application.