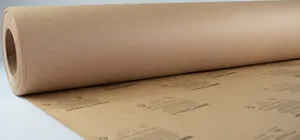

VCI Paper, also known as Vapor Corrosion Inhibitor paper, is a kraft packaging paper manufactured with integrated Vapor Corrosion Inhibitor Technology. VCI Paper releases inhibitor molecules that vaporize and move through the air space inside the package to protect metal parts. These molecules then form a thin, invisible, and protective molecular layer on metal surfaces. This layer interrupts the corrosion process caused by oxygen, moisture, and airborne contaminants.

Unlike traditional rust preventatives such as oils or greases, VCI Paper protects metals without leaving residues. After you remove the parts from the packaging, the protective molecules naturally dissipate. As a result, metal components are clean, dry, and ready for use.

VCI Paper is available in a wide range of sizes, basis weights, and corrosion inhibitor types to match different metals and environments. Manufacturers supply VCI Paper in rolls, pre-cut sheets, or custom printed formats. While most options use kraft paper, reinforced versions that are poly-coated or scrim-reinforced add strength and durability for demanding packaging applications.

How Does VCI Paper Work?

VCI Paper works through vapor-phase corrosion protection. When you enclose VCI Paper around or near metal parts, Vapor Corrosion Inhibitor molecules volatilize and fill the enclosed space. These molecules form a microscopic barrier on the metal surface, blocking moisture, oxygen, and corrosive ions from initiating electrochemical corrosion reactions.

Because the protection occurs in the vapor phase, VCI Paper can protect complex geometries, recessed areas, and internal cavities that are difficult to coat with traditional surface-applied rust preventatives.

VCI Poly vs Paper: Key Differences

VCI technology has evolved significantly since its early development in the 1940s. Early VCI chemistries applied to paper diffused rapidly, flaked off, and trapped moisture at the metal surface. These limitations led manufacturers to explore safer and more effective delivery methods.

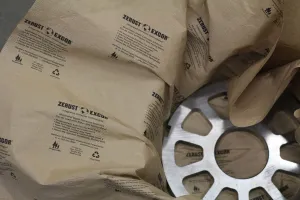

In the late 1970s, Northern Technologies International Corporation introduced major advancements by developing improved VCI chemistry and successfully impregnating it into polyethylene films. By the early 1980s, similar modern VCI technology was also applied to VCI Paper under the ZERUST® brand, giving users flexible packaging options and prompting a common question: when should you use VCI Paper versus VCI Poly?

Advantages of VCI Poly Film

VCI Poly film offers several performance benefits, particularly in high-moisture or long-term storage environments:

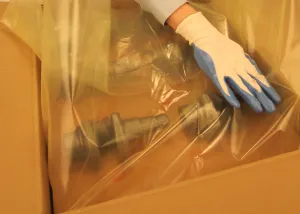

- It provides a superior moisture barrier, reducing water vapor transmission and limiting humidity exposure.

- It simplifies handling, as parts can be placed directly into bags or liners that are easy to seal and reopen.

- It protects against dust and airborne contaminants during storage and transit.

- It delivers long shelf life and extended corrosion protection when stored and applied correctly.

Advantages of VCI Kraft Paper

VCI Kraft Paper continues to play an important role in many packaging programs due to its unique benefits:

- It allows fast diffusion of VCI molecules, helping corrosion protection reach metal surfaces quickly.

- It typically offers a lower material cost compared to VCI Poly.

- It is easy to form, wrap, and conform around parts with irregular shapes.

- When crumpled, it provides cushioning and stabilization during shipping.

Learn When to Use VCI Paper vs VCI Poly

Choosing the right VCI packaging can improve corrosion protection and reduce overall costs.

When to Use VCI Paper

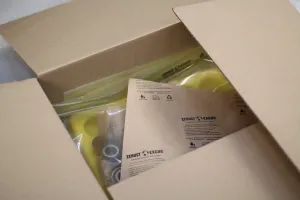

VCI Paper is commonly used for interleaving, wrapping, and cushioning metal parts during storage or shipment. It works well for short- to medium-term protection, indoor storage, and applications where ease of handling is important. Many packaging programs combine VCI Paper with Poly products to maximize corrosion protection while improving part stability and packaging efficiency.

For example, a container may be lined with a gusset bag while individual parts are wrapped in VCI Paper. Interleaving layers of paper or poly sheeting helps increase Vapor Corrosion Inhibitor saturation inside the package and ensures protection reaches all internal spaces.

Choosing the Right VCI Packaging Solution

Both VCI Paper and Poly offer proven corrosion protection when applied correctly. The best solution depends on factors such as storage duration, humidity levels, shipping conditions, part geometry, and handling requirements. In many applications, combining both materials delivers the most effective and cost-efficient results.

Whichever option you choose, ZERUST® can help evaluate your corrosion risks and design a packaging program tailored to your operation. ZERUST® specialists analyze your current processes, perform packaging and fluid audits, and recommend the right products, procedures, and protection strategies to help you achieve reliable, long-term corrosion control.

Need Help Selecting the Right Product?

ZERUST® experts can evaluate your corrosion risks and recommend the most effective VCI packaging solution.