We are commonly asked what happens after VCI packaging is removed from metal parts. After opening ZERUST®/EXCOR® VCI packaging, the corrosion-inhibiting vapor molecules that were protecting the metal surface begin to disperse into the surrounding air. As a result, under normal ambient conditions, this dissipation typically occurs within one to two hours.

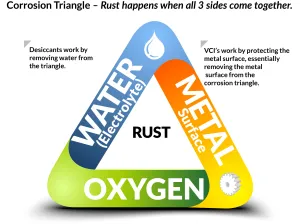

During storage, ZERUST®/EXCOR® VCI packaging continuously releases corrosion inhibitors that form a temporary, invisible protective layer on exposed metal surfaces. This layer interrupts the electrochemical reactions that cause corrosion while the part remains enclosed. Consequently, removing the packaging stops vapor replenishment, allowing the protection to dissipate naturally over time.

Explore ZERUST® VCI Packaging Films

Learn how ZERUST® VCI packaging films provide reliable, residue-free corrosion protection during storage and transport.

How long does VCI protection remain after packaging removal?

In the first one to two hours after removal, residual VCI molecules continue to provide short-term protection as they disperse. Furthermore, this brief window allows operators to inspect, assemble, or transfer parts without immediate corrosion risk in controlled environments.

The exact duration depends on airflow, temperature, and humidity. Higher airflow and elevated temperatures accelerate dissipation, while still indoor conditions may allow protection to persist slightly longer.

Does VCI leave residue on metal surfaces after removal?

After removing the VCI packaging, ZERUST® VCI technology does not leave oily films, sticky residues, or surface buildup. Once the vapor molecules dissipate, metal parts remain clean, dry, and ready for use, coating, or assembly.

VCI technology delivers a residue-free surface, eliminating the cleanup required by traditional rust preventative coatings before downstream processing.

What happens after VCI packaging is removed in humid environments?

Removing the packaging increases the influence of environmental exposure on corrosion performance. In high-humidity areas, coastal locations, or environments with corrosive contaminants, bare metal surfaces may begin to corrode quickly after VCI dissipates.

If parts remain exposed for extended periods after removal, use additional corrosion control measures such as re-packaging, controlled storage conditions, or supplemental rust preventatives.

What happens after VCI packaging is removed and parts are re-packaged?

When corrosion protection remains necessary, safely re-package parts with fresh or properly stored ZERUST®/EXCOR® VCI materials. Re-enclosing the part allows VCI vapor molecules to rebuild the protective atmosphere inside the package.

For best results, ensure parts are dry, free of corrosive residues, and fully enclosed before sealing the package again.

Best practices after VCI packaging is removed

To minimize corrosion risk after removal:

- Move parts promptly into service or controlled storage

- Avoid prolonged exposure to humid or outdoor environments

- Re-package with VCI if storage or shipment continues

- Combine VCI packaging with environmental controls for critical components

Following these practices helps maintain corrosion protection continuity and prevents unexpected surface degradation.

Talk to a ZERUST® Corrosion Expert

Have questions about VCI protection, post-removal handling, or selecting the right corrosion solution for your application? Our corrosion experts can help you choose the most effective ZERUST® system.