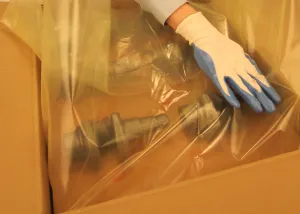

VCI packaging for corroded parts helps slow further corrosion, but it does not remove rust that already exists. When parts with visible corrosion are enclosed in properly selected ZERUST® VCI products, the vapor corrosion inhibitors protect exposed metal surfaces by interrupting the electrochemical corrosion process. This protection stabilizes the condition of the part and helps prevent corrosion from spreading or worsening during storage or shipment.

How VCI Works on Already Corroded Metal

Vapor Corrosion Inhibitor Technology (VCI) works by releasing corrosion-inhibiting vapor molecules into a sealed enclosure. These molecules are attracted to metal surfaces, where they form a microscopic protective layer. On corroded parts, this layer:

- Protects areas that are not yet rusted

- Slows corrosion activity at the edges of existing rust

- Helps prevent new corrosion from forming on adjacent surfaces

However, VCI molecules do not chemically convert, dissolve, or remove existing corrosion. The rust remains in its current state unless it is mechanically or chemically removed beforehand.

What VCI Packaging Will Not Do

It is important to understand the limitations of VCI packaging for corroded parts:

- VCI does not clean or remove rust

- VCI does not restore pitted or damaged metal

- VCI does not reverse corrosion that has already formed

VCI should be viewed as a corrosion control and prevention solution, not a rust removal method.

Best Practices Before Using VCI Packaging on Corroded Parts

To achieve the best results when packaging already corroded components, consider the following steps:

- Assess the severity of corrosion: Light surface rust may be stabilized, while heavy corrosion should be treated first.

- Remove rust when possible: Mechanical cleaning or rust removers can restore metal surfaces before packaging.

- Ensure parts are dry and free of corrosive residues: Trapped moisture or salts can continue to drive corrosion even inside packaging.

- Select the correct ZERUST® VCI product: Film, paper, emitters, or combinations may be recommended depending on storage duration and environment.

Following these steps allows VCI packaging to protect clean metal surfaces more effectively after rust treatment.

When VCI Packaging for Corroded Parts Is Most Useful

VCI packaging is especially valuable when:

- Parts must be shipped or stored before rust removal is possible

- Corrosion has been stabilized but not fully remediated

- Cleaned components need protection after rust removal

- Temporary storage is required between processing steps

In these situations, VCI helps prevent additional corrosion damage while preserving the current condition of the part.

Should Rust Be Removed Before Packaging?

In most cases, yes. Removing rust before applying VCI packaging delivers the highest level of corrosion protection and extends part life. After rust removal, VCI packaging protects freshly exposed metal surfaces without leaving oils, greases, or residues.

If rust removal is not immediately possible, VCI packaging can still provide value by slowing further corrosion until proper treatment can be performed.

Learn More About Rust Removal and Corrosion Protection

If you are dealing with parts that already show signs of corrosion, understanding when to remove rust and when to stabilize parts with VCI is critical. ZERUST® offers both corrosion prevention solutions and rust removal technologies to support the full metal protection process.

Need to remove rust before packaging?

ZERUST® rust removal products help eliminate existing corrosion so VCI packaging can protect clean metal surfaces more effectively.

Related Products

AxxaClean™ 2048 is a moderate-acting (nonhazardous) safe rust remover designed to eliminate medium rust and tarnish, even in the most hard-to-reach cracks and crevices. Additionally, it is mildly acidic (about 2.5 pH), similar to a soda drink that cleans and deoxidizes ferrous metals, brass, copper, and various alloys without leaving a gray residue.

AxxaClean™ 3048 is a rapid-acting industrial rust remover designed to eliminate heavy rust and tarnish, even in the most hard-to-reach cracks and crevices. Additionally, AxxaClean™ 3048 effectively cleans ferrous and yellow metals of rust and tarnish, and with a pH of around 1, it minimizes disposal concerns.