Flash rust is a common challenge immediately after parts washing, especially when freshly cleaned metal surfaces are exposed to moisture, humidity, or residual rinse water. Without protection, bare metal can begin oxidizing within minutes. To prevent flash rust after washing, corrosion protection must be integrated directly into the cleaning process rather than applied later.

ZERUST® offers a proven solution through its AxxaWash™ line of part washing fluids with built-in rust inhibitors. These cleaners remove oils, machining fluids, and soils while actively preventing flash rust during the critical transition from washing to drying.

How Integrated Cleaners Help Prevent Flash Rust After Washing

Unlike conventional alkaline or neutral cleaners that leave metal surfaces unprotected, ZERUST® AxxaWash™ formulations deposit a light, temporary corrosion-inhibiting layer on the metal surface as part of the wash cycle. This protection begins immediately and helps prevent flash rust after washing, even during staging, handling, or short-term storage.

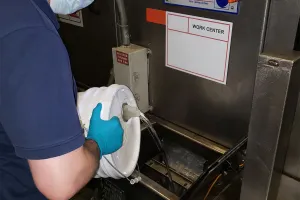

AxxaWash™ KF-123, KF-124, and KMS-220 are low to very low foaming cleaners designed for spray washers, immersion systems, and ultrasonic cleaning equipment. These products effectively remove light to heavy hydrocarbon soils, including oils and greases, while reducing the risk of flash rust formation once parts exit the washer.

Reducing Process Steps While Improving Corrosion Control

Manufacturers often attempt to prevent flash rust after washing by adding secondary inhibitors, post-wash sprays, or accelerated drying steps. ZERUST® AxxaWash™ products eliminate the need for many of these extra steps by combining cleaning and corrosion protection in a single operation. This approach helps improve process efficiency while delivering consistent rust prevention results.

Depending on the metal type, soil load, water quality, and required protection window, ZERUST® offers multiple AxxaWash™ formulations to meet specific operational needs. These solutions are suitable for steel and other ferrous components that are especially vulnerable to flash rust after washing.

Explore ZERUST® Industrial Cleaners and Degreasers

Learn how ZERUST® AxxaWash™ cleaners combine effective soil removal with built-in corrosion protection to help prevent flash rust after washing.

Selecting the Right Solution to Stop Flash Rust

The most effective way to prevent flash rust after washing depends on factors such as washer design, rinse stages, part geometry, and downstream handling time. ZERUST® technical service representatives can help evaluate your process and recommend the appropriate AxxaWash™ cleaner and inhibitor level to match your application.

For expert guidance on your specific operation, you can contact ZERUST®/EXCOR® to speak directly with a technical service representative.

Need Help Stopping Flash Rust After Washing?

Speak with a ZERUST® technical service representative to identify the right cleaning and corrosion protection solution for your process, equipment, and metals.