In short, rust inhibitors prevent corrosion, while rust converters treat existing rust.

Rust Inhibitor vs Rust Converter

When comparing a rust inhibitor vs rust converter, the most important factor is the condition of the metal.

- Rust inhibitors are ideal for clean, dry, or freshly processed metal parts. They are commonly used during manufacturing, storage, and shipment to prevent rust from forming in the first place.

- Rust converters are best suited for heavily corroded surfaces that cannot be fully cleaned. They stabilize rust but do not restore the original metal surface.

Because of this, rust inhibitors are preferred in controlled industrial environments, while rust converters are typically used in maintenance or restoration scenarios.

Rust Inhibitor vs Rust Remover

The comparison between rust inhibitor vs rust remover highlights another key distinction.

- A rust remover eliminates rust by dissolving it using acidic or chelating chemistry. This process removes corrosion but also exposes bare metal, which can quickly flash rust if left unprotected.

- Rust inhibitors, on the other hand, do not remove rust. Instead, they protect metal surfaces before corrosion begins and help maintain surface integrity over time.

As a result, rust removers are often followed by a rust inhibitor to prevent corrosion from returning.

Rust Converter vs Rust Remover

The difference between a rust converter vs rust remover lies in how each product treats corrosion.

Rust removers physically remove rust from the metal surface. This leaves clean metal that typically requires immediate protection.

Rust converters chemically change rust into a stable layer that remains on the surface. While this slows further corrosion, it does not provide long-term protection on its own.

Neither option replaces the need for a rust inhibitor when long-term corrosion prevention is required.

Remove Existing Rust Effectively

When rust is already present, ZERUST rust removers help eliminate corrosion and prepare metal surfaces for proper protection and finishing.

When Should You Use a Rust Inhibitor?

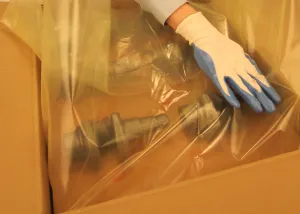

Rust inhibitors are best used when metal parts are clean and corrosion-free. They are commonly applied:

• After machining or washing

• Before storage or shipment

• During work in progress, manufacturing stages

• Inside enclosed spaces where moisture control is needed

Products such as ZERUST® Axxanol™, Axxatec™, and AxxaCoat™ solutions use proven corrosion-inhibiting technology to protect metal surfaces before rust can form.

Choosing the Right Rust Protection Solution

Understanding the difference between rust inhibitor and rust converter helps ensure the correct product is used for each application.

If rust is already present, a rust remover or converter may be needed first. However, once the metal surface is restored or cleaned, a rust inhibitor is essential to prevent corrosion from returning.

For best results, many industrial corrosion strategies combine cleaning, rust removal if needed, and preventative rust inhibitors as the final protection step.

Prevent Rust Before It Starts

For long-term corrosion prevention, ZERUST® Axxanol™, Axxatec™, and AxxaCoat™ rust inhibitors protect metal surfaces before rust can form and help maintain part quality during storage, processing, and shipment.

Axxanol™ 33 is a rust preventative oil that forms a light oily film, providing powerful corrosion protection against aggressive environments such as salt air and humidity.

Axxanol™ 34CD is a solvent-based coating that forms a very light, oily, near dry-to-touch rust preventative film that provides powerful corrosion protection against aggressive environments.

Axxanol™ A35CD-32 is a solvent-based, non-staining rust preventative that forms a clear, thin, near dry-to-touch RP film. As a result, it provides powerful corrosion protection against aggressive environments, such as salt air and humidity.

Axxanol™ Spray-G is a sprayable rust preventative grease that provides the protection of a grease in the convenience of a sprayable form. It’s designed to protect metal parts, equipment, and assemblies during long-term indoor and outdoor storage and challenging overseas shipping applications where a removable coating is essential.

Axxanol™ Z-Maxx Anti-Corrosion Grease Series consists of two products, Axxanol™ Z-Maxx and Z-Maxx LV. Z-Maxx is a thick NLGI 2 grease and is also offered as a lower viscosity (LV) NLGI 0 grease that is designed for spreadability and light lubrication properties.

Axxatec™ 30C is a water-based rust Inhibitor designed to provide short-term indoor storage and in-transit protection. In addition to the corrosion protection offered, Axxatec™ 30C may also be used as a light-duty cleaner-rust preventative combination product.

Axxatec™ 80C is a water-based liquid concentrate rust preventative designed to provide long-lasting protection during indoor storage, shipping, and assembly.

AxxaCoat™ 90B HFS is a sprayable high-flash outdoor rust preventative coating designed to protect metal parts and assemblies during long-term indoor and outdoor storage and challenging overseas shipping applications.