Page 5 of 6

ZERUST® VCI Film Additives & Custom Options

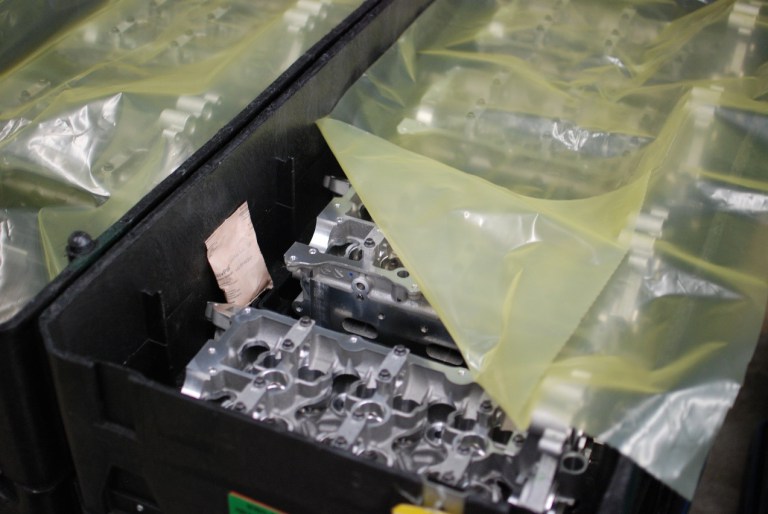

ZERUST®/EXCOR® (Vapor or Volatile Corrosion Inhibitor) VCI film, poly bags, and tubing are produced using a process known as blown film extrusion. The polyethylene is melted and extruded into sheeting which is then slit, folded, or sealed to the desired size and dimensions. With ZERUST’s vast manufacturing network, we have over 100 extrusion lines in

6 Straight Forward Steps to Get Rust Under Control

Opening up a container to discover corrosion on metal items is frustrating. It often means lost time, missed deadlines, and unhappy people in your supply chain. The loss or rework of the corroded items plus the impact on business all total up to a significant cost. Corrosion can be complicated and may be caused by

5 Best Practices for VCI Packaging Storage

Do you currently use Volatile Corrosion Inhibitor (VCI) packaging to protect metals from corrosion? Are you wondering about the best way to store VCI packaging, such as rolls of poly sheeting and VCI gusset bags, before use? Since VCI products are designed to diffuse their protective chemistry into open spaces, the key to preserving their effectiveness

RP Oils or VCIs: Which Protection Method is Best for Me?

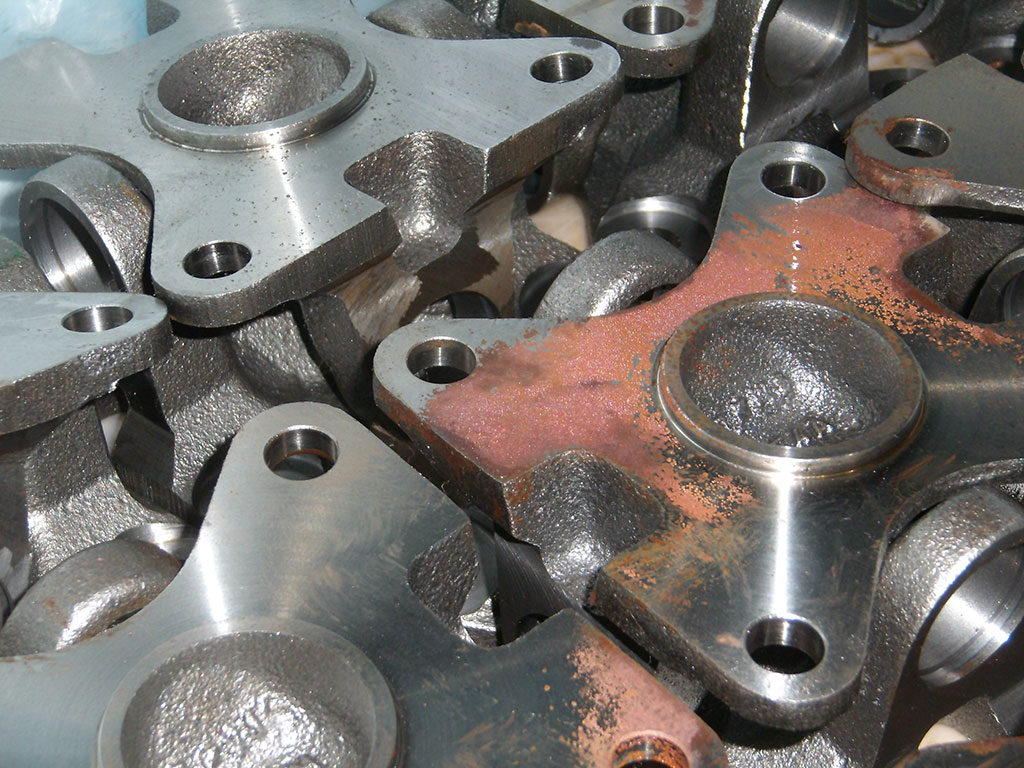

When considering corrosion protection methods, plenty of options are available. The two methods most used for protecting metals during the manufacturing processes of shipment and storage are corrosion inhibitor liquids and VCI (volatile corrosion inhibitor) packaging products. Corrosion inhibitor liquids, also known as “Rust Preventatives” (RPs) or oils, are available in a wide range of

Is There a Rust Season or is it Open Season for Rust?

When you mention the words “rust season” to someone in the metalworking industry, you may get a dry smile. Their immediate answer is typically summer, when high heat and humidity create the perfect conditions for corrosion. Unfortunately, that answer is usually quickly followed by reasons why their metals can corrode the rest of the year.

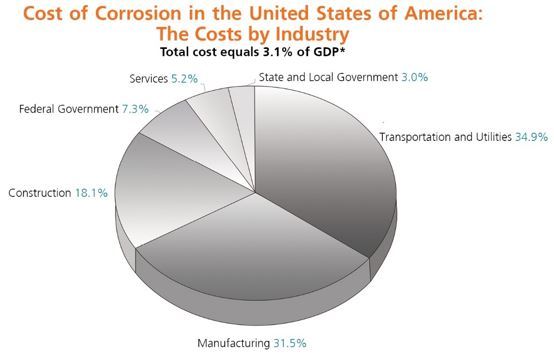

What Does Corrosion Really Cost You and The Environment?

April was Earth Month, but did you know Corrosion Awareness Day also occurred during April? While this date isn’t as well-known, preventing corrosion is a crucial way to help the environment and conserve natural resources. Corrosion affects you, whether you are a civil engineer overseeing infrastructure, a quality-control manager at a metalworking facility, or have

What is the Difference Between VCI Shrink and VCI Stretch Wrap?

Often people interchange the product names VCI Shrink Film and VCI Stretch Wrap, but they are two distinct packaging films. Both Vapor Corrosion Inhibitor (VCI) protection-infused films possess different mechanical properties. Vapor Corrosion Inhibitor (VCI) stretch film VCI stretch film tightly bundles items such as pallets. It’s similar to plastic wrap and has a sticky quality

Does Corrugated Affect Corrosion & What Can You Do About It?

When shipping metal parts in cardboard corrugated boxes, do you allow the unprotected parts to touch the box? If so, then the corrugated may be the source of the corrosion. When cardboard boxes are manufactured, the paper begins as pulp and is then dissolved using nitric acid. In order to neutralize the acid before forming

Corrosion Prevention: When to Use VCI Diffusers with VCI Packaging

Volatile Corrosion Inhibitor (VCI) Packaging is an effective way to prevent corrosion on metals. When packed correctly, VCI packaging can protect clean metals for years in shipping and storage. Typical VCI packaging products are VCI poly sheeting, VCI bags, VCI Kraft paper, and other VCI wraps. These packaging products are used to line containers or create

VCI Poly vs VCI Paper? The Advantages and Disadvantages Explained

Volatile Corrosion Inhibitors (VCIs) have been around since the 1940’s, when a product named Dichan was introduced into market. Dichan consisted of dicyclohexylamine-nitrite, which was described as a vapor phase corrosion inhibitor that had sufficient vapor pressure to release corrosion inhibiting molecules into the surrounding area. Eventually, this chemistry began to be coated onto paper,