Page 3 of 3

What is the Difference Between VCI Shrink and VCI Stretch Wrap?

Often people interchange the product names VCI Shrink Film and VCI Stretch Wrap, but they are two distinct packaging films. Both Vapor Corrosion Inhibitor (VCI) protection-infused films possess different mechanical properties. Vapor Corrosion Inhibitor (VCI) stretch film VCI stretch film tightly bundles items such as pallets. It’s similar to plastic wrap and has a sticky quality

Corrosion Prevention: When to Use VCI Diffusers with VCI Packaging

Volatile Corrosion Inhibitor (VCI) Packaging is an effective way to prevent corrosion on metals. When packed correctly, VCI packaging can protect clean metals for years in shipping and storage. Typical VCI packaging products are VCI poly sheeting, VCI bags, VCI Kraft paper, and other VCI wraps. These packaging products are used to line containers or create

VCI Poly vs VCI Paper? The Advantages and Disadvantages Explained

When comparing VCI Poly vs VCI Paper, it is important to understand how each material evolved and how performance differences affect real-world corrosion protection. Vapor Corrosion Inhibitors, or VCIs, have been used since the 1940s, but not all VCI delivery methods perform the same. This guide explains the advantages and disadvantages of VCI Poly vs

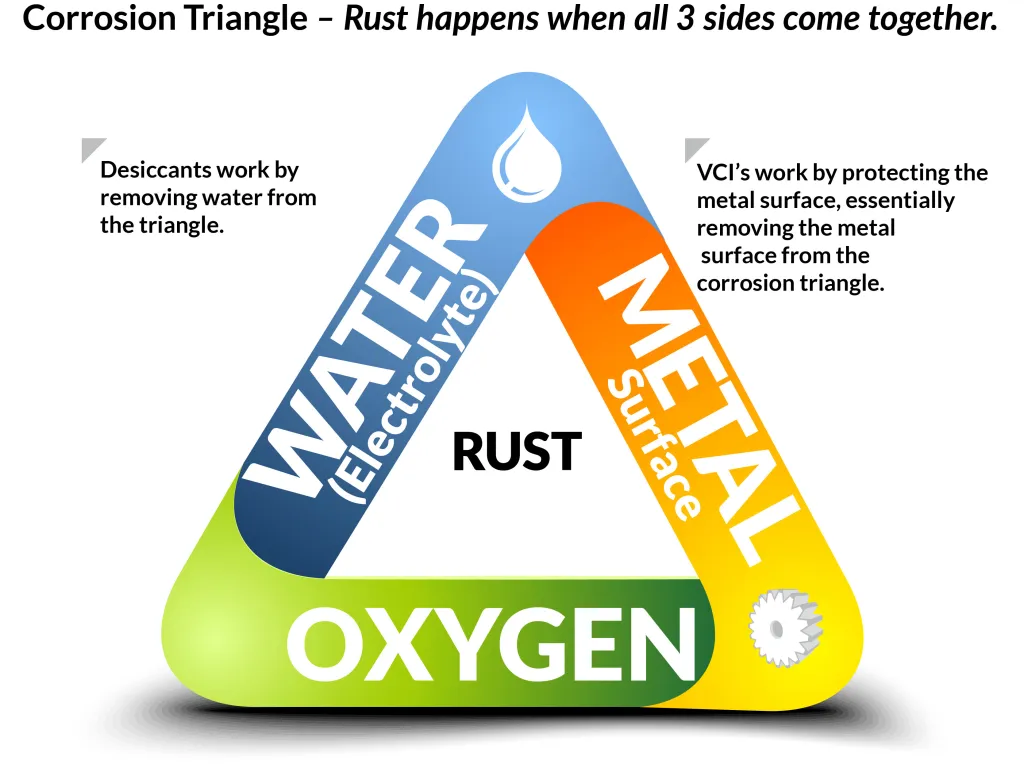

VCIs vs Desiccants. How do they Differ?

When evaluating VCI vs desiccants for corrosion protection, it’s important to understand that moisture control and corrosion inhibition are not the same thing. While desiccants absorb humidity, Vapor Corrosion Inhibitors (VCI) actively protect metal surfaces inside sealed packaging. Choosing the wrong method can lead to rust, warranty claims, or shipment delays. Let’s break down the