Page 2 of 3

5 Reasons the Steel Coil Industry Prefers VCI Paper and Poly for Optimal Steel Coil Corrosion Protection

Corrosion is a significant challenge in the steel coil industry, causing damage to steel coils and resulting in decreased productivity and profitability. As a result, rust-preventative coatings have commonly been used by steel coil suppliers and manufacturers to provide steel coil corrosion protection during storage and transportation. However, one solution in the steel coil industry has

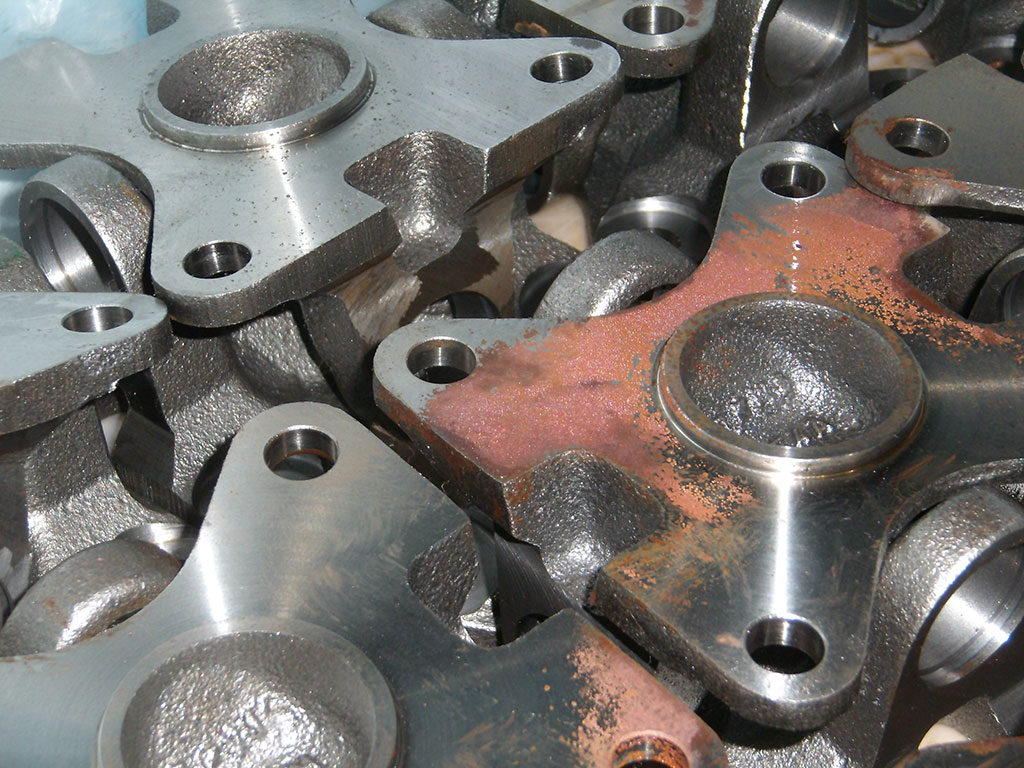

What to Do When Rust Prevention Fails?

In the manufacturing world, many companies go to great lengths to select products and processes to prevent rust and corrosion from forming on their valuable metal assets during transit and storage. They will probably incorporate volatile corrosion inhibitor (VCI) packaging, rust preventative (RP) coatings, desiccants, or some combination of them. But what happens when their

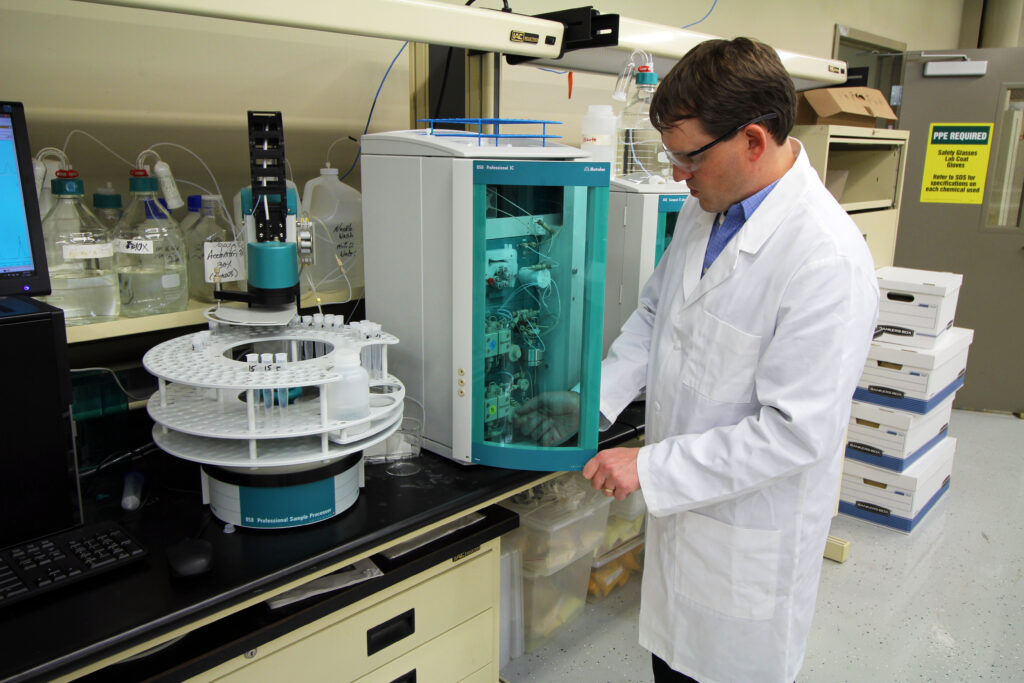

How to use ZERUST® VCI Products Correctly

For nearly 5 decades now, manufacturers and OEMs across the globe have been incorporating ZERUST® Vapor Corrosion Inhibitor (VCI) products into their packaging applications to prevent rust and corrosion during shipping and storage of their metal goods. However, despite years of experience, not everyone fully understands how VCI works and how to use it correctly

ZERUST® VCI Film Additives & Custom Options

ZERUST®/EXCOR® (Vapor or Volatile Corrosion Inhibitor) VCI film, poly bags, and tubing are produced using a process known as blown film extrusion. The polyethylene is melted and extruded into sheeting which is then slit, folded, or sealed to the desired size and dimensions. With ZERUST’s vast manufacturing network, we have over 100 extrusion lines in

6 Straight Forward Steps to Get Rust Under Control

Opening up a container to discover corrosion on metal items is frustrating. It often means lost time, missed deadlines, and unhappy people in your supply chain. The loss or rework of the corroded items plus the impact on business all total up to a significant cost. Corrosion can be complicated and may be caused by

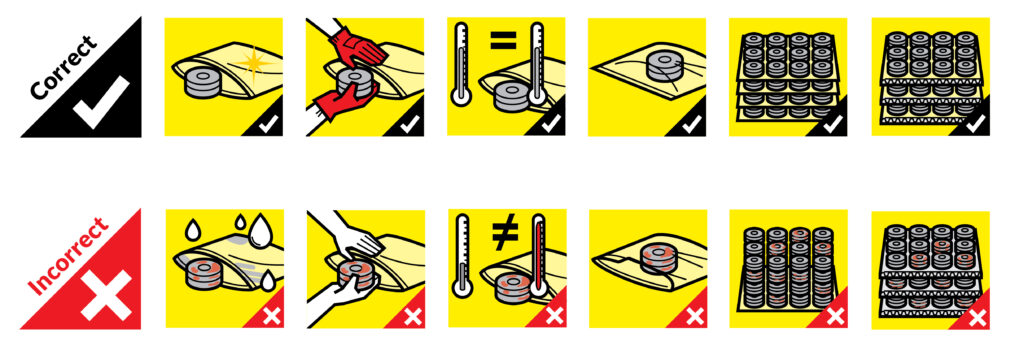

5 Best Practices for VCI Packaging Storage

Do you currently use Volatile Corrosion Inhibitor (VCI) packaging to protect metals from corrosion? Are you wondering about the best way to store VCI packaging, such as rolls of poly sheeting and VCI gusset bags, before use? Since VCI products are designed to diffuse their protective chemistry into open spaces, the key to preserving their effectiveness

RP Oils or VCIs: Which Protection Method is Best for Me?

When considering corrosion protection methods, plenty of options are available. The two methods most used for protecting metals during the manufacturing processes of shipment and storage are corrosion inhibitor liquids and VCI (volatile corrosion inhibitor) packaging products. Corrosion inhibitor liquids, also known as “Rust Preventatives” (RPs) or oils, are available in a wide range of

What is the Difference Between VCI Shrink and VCI Stretch Wrap?

Often people interchange the product names VCI Shrink Film and VCI Stretch Wrap, but they are two distinct packaging films. Both Vapor Corrosion Inhibitor (VCI) protection-infused films possess different mechanical properties. Vapor Corrosion Inhibitor (VCI) stretch film VCI stretch film tightly bundles items such as pallets. It’s similar to plastic wrap and has a sticky quality

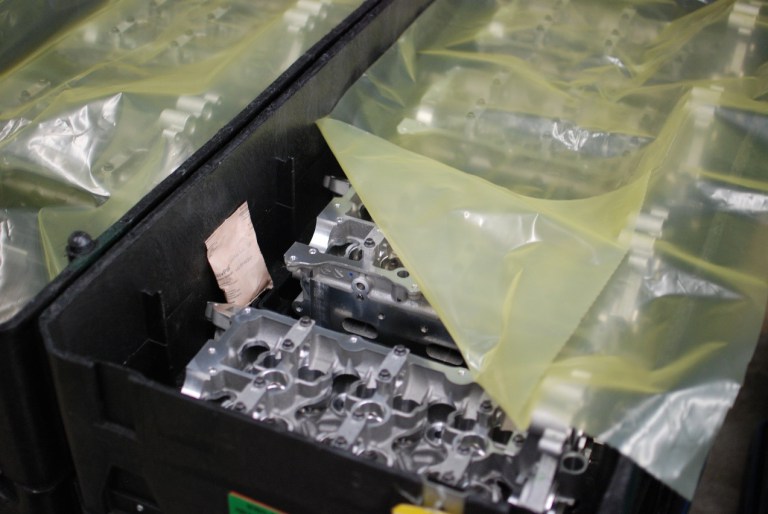

Corrosion Prevention: When to Use VCI Diffusers with VCI Packaging

Volatile Corrosion Inhibitor (VCI) Packaging is an effective way to prevent corrosion on metals. When packed correctly, VCI packaging can protect clean metals for years in shipping and storage. Typical VCI packaging products are VCI poly sheeting, VCI bags, VCI Kraft paper, and other VCI wraps. These packaging products are used to line containers or create