While it is possible to use ActivDri™ packets with non-ZERUST® VCI bags, we do not recommend doing so due to concerns about the compatibility between VCI chemistries. Always test before use if you intend to use ActivDri™ packets with other non-ZERUST® VCI products. We would also highly recommend using both ActivDri™ packets and ZERUST® VCI bags concurrently, providing more robust corrosion protection for the metal components. Note that the ActivDri™ packets are a long-term (up to 12 months‡ depending on application and humidity levels) fast-acting corrosion prevention and moisture control product, while the ZERUST® VCI bag provides longer-term protection (for many months to years‡). If your company decides to use non-VCI bags, such as plain LDPE bags, with ActivDri™ packets, be sure to check the usage level and increase the number of ActivDri™ packets whenever necessary to ensure ample corrosion protection for your application.

ZERUST® ActivDri™ PWA Packets

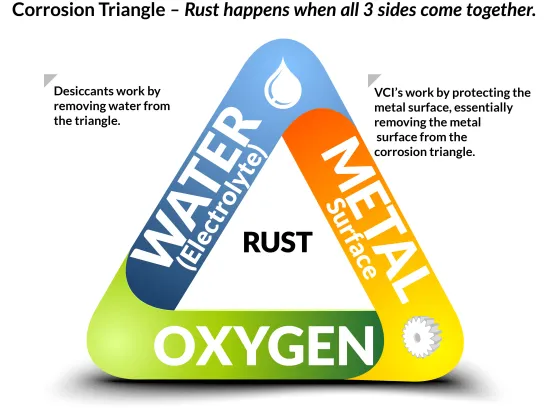

ZERUST®/EXCOR® ActivDri™ PWA Packets are patent-pending, economical, effective, and easy-to-use dual-action, moisture control Vapor Corrosion Inhibitor (VCI) packets that protect against environmental contaminants and humidity that aggressively corrode metal parts, components, electronics, and electrical components/equipment.

Features

- Protects metal parts and electrical components from corrosion

- Reduces the risk of delays, shutdowns, etc., due to electrical failures that result in power outages

- Extend the service life of expensive electrical equipment and components

- Prevents moisture condensation

- Prevents sulfur corrosion in high-humidity environments that contain SOx

- Minimal user training is required

- Easy to apply, as well as use

- Effective in mitigating corrosion issues through a dual mechanism of desiccation and VCI emission

- Safe to dispose of in industrial landfills, as well as incineration

Product Description

Use ActivDri™ PWA dual-acting moisture and corrosion control packets to protect highly sensitive metal parts and electrical components from corrosion damage during operation, shipping, and storage.

ActivDri™ PWA Packets diffuse invisible, odorless, and non-toxic ZERUST® Vapor Corrosion Inhibitors (VCI) that settle onto exposed metal surfaces inside the packaging or enclosure. Once removed from the packaging, the VCI will dissipate from the metal surfaces, allowing immediate painting, welding, or further processing. ActivDri™ PWA Packets ferrous metals and aluminum surfaces for up to 12 months‡ in a sealed enclosure and is compatible with yellow metals and silver. Additionally, ActivDri™ PWA Packets comply with Global Automotive Declarable Substance, TSCA, REACH, RoHS, and TRGS615 requirements.

Why Choose ZERUST®?

For over 50 years, beginning with the invention of Vapor Corrosion Inhibiting (VCI) film, ZERUST® has led the market in quality corrosion solution products. Furthermore, we dedicate ourselves to providing expert corrosion management services and further adding solutions for our customers. In addition, ZERUST® users have access to on-site support from ZERUST®/EXCOR® representatives in more than 70 countries. As a result, our customers have peace of mind when they choose ZERUST® for corrosion control management.

Resources

Availability

ZERUST®/EXCOR® ActivDri™ PWA Corrosion Prevention and Moisture Control Packets are in stock and sold in cases. For further ordering information, contact your ZERUST®/EXCOR® representative.

| Part Number | Model | Volume of protection (Up to)‡ | Quantity | |

|---|---|---|---|---|

| 375-M-00212 | PWA5 | 3.5 ft³ (0.1 m³)‡ | 1,000/Case | |

| 375-M-00213 | PWA10 | 7 ft³ (0.2 m³)‡ | 500/Case | |

| 375-M-00214 | PWA25 | 17.5 ft³ (0.5 m³)‡ | 200/Case | |

| 375-M-00215 | PWA50 | 35 ft³ (1.0 m³)‡ | 100/Case | |

| 375-M-00210 | PWA100 | 53 ft³ (1.5 m³)‡ | 50/Case |